Tensile strength and Brinell hardness are two important indicators to evaluate the properties of nodular cast iron. The test results of mechanical properties of as cast ductile iron samples with different silicon content are shown in the table. It can be seen that the tensile strength, yield strength, elongation and hardness of QT450-10 ductile iron with silicon content of 2.92% are 441 MPa, 325 MPa, 17% and 128 HBW respectively; When the silicon content is 4.59%, the tensile strength of high silicon ductile iron is 683 MPa, the yield strength is 488 MPa, the elongation is 17.5%, and the highest hardness is 186.1 HBW. With the increase of silicon content, the mechanical properties of high silicon ductile iron are gradually enhanced.

| Sample No ω (Si) (%) | Tensile strength/MPa | Yield strength/MPa | Yield ratio | Elongation (%) | Hardness (HBW) |

| A(2.92) | 441 | 325 | 0.737 | 17 | 128 |

| B(3.68) | 527 | 425 | 0.806 | 18 | 149 |

| C(4.22) | 601 | 512 | 0.852 | 17 | 174.6 |

| D(4.59) | 683 | 588 | 0.861 | 17.5 | 186.1 |

With the increase of silicon content, the strength and hardness of high silicon ferrite ductile iron increase, and the yield ratio is also getting higher and higher. The yield ratio refers to the ratio of material yield strength to tensile strength. After yielding, the material changes from elastic deformation to plastic deformation. The material with high yield ratio has strong resistance to deformation, is not easy to plastic deformation, and can save materials and reduce costs; The size of spheroidal graphite decreases gradually, so that it has little effect on splitting the metal matrix. The increase of silicon content leads to the gradual increase of eutectic temperature of high silicon nodular cast iron, which increases the undercooling at the front of molten iron solidification, increases the nucleation rate of ferrite, refines the grains, increases the number of grain boundaries, increases the resistance to dislocation movement, and increases its strength, hardness and elongation; However, with the increase of silicon element, the solute atoms will form a Coriolis air mass near the dislocation, which reduces the plastic deformation ability of the material, so the elongation decreases. Under the combined effect of both, the elongation of the high silicon ductile iron sample is basically unchanged.

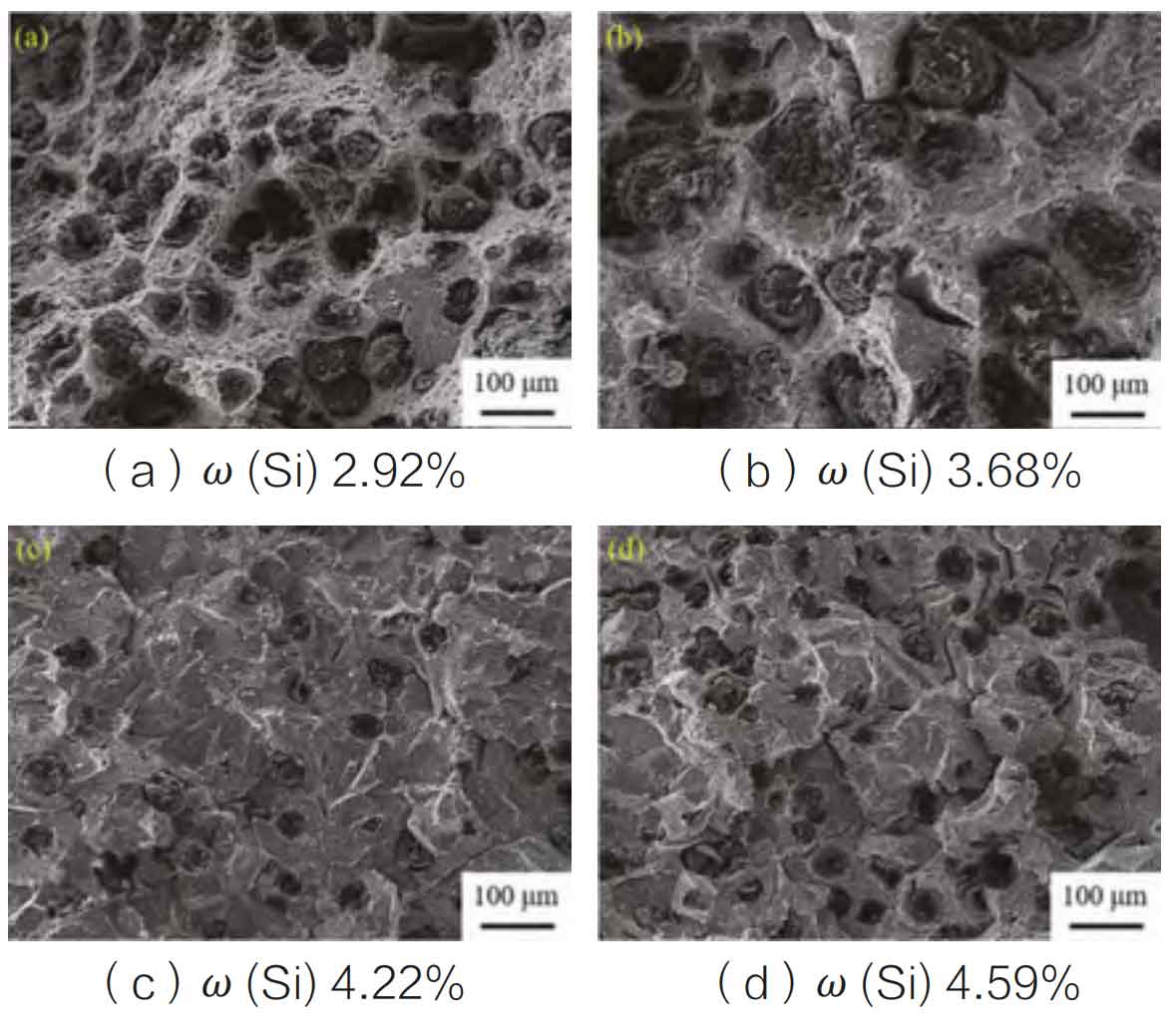

In order to study the fracture characteristics of high silicon ductile iron, the tensile fracture morphology was observed by SEM, as shown in the figure.

When the silicon content is 2.92%, the fracture morphology of QT450-10 sample is mainly composed of dimple morphology, which belongs to ductile fracture. Spherical graphite is distributed in the center of the dimple, and some graphite falls off from the dimple. The dimple depth is shallow. There are cleavage characteristics in some areas, but the cleavage area is small; When the silicon content is 3.68%, the number of dimples in the high silicon ductile iron sample decreases but the depth is deeper, which belongs to ductile fracture, but there is local transgranular fracture. The more dimples are, the deeper the depth is, the better the plasticity of the material is; When the silicon content is 4.22%, the fracture morphology of the high silicon ductile iron sample is a large area of cleavage surface, which belongs to brittle fracture; When the silicon content is 4.59%, the number of dimples in the fracture morphology of high silicon ductile iron sample is small, there are cleavage planes, and there are intergranular fractures. As silicon has a strong solid solution strengthening effect on ferrite, the ferrite lattice is distorted, and the plastic deformation ability of ferrite is weakened. Therefore, with the increase of silicon content, the dimple depth becomes shallow, and the fracture of ductile iron changes from ductile fracture to brittle fracture. However, since the matrix fabric is all ferrite matrix and the graphite is fine and uniform, the high silicon ductile iron still shows good macro plasticity.