As the nodular cast iron treated at 1560 ° C has been obviously white cast, it is not satisfied with the requirements of the matrix structure of nodular cast iron. Therefore, only nodular cast iron treated at 1510 ° C and 1460 ° C was selected as the research object for mechanical property test and fracture analysis.

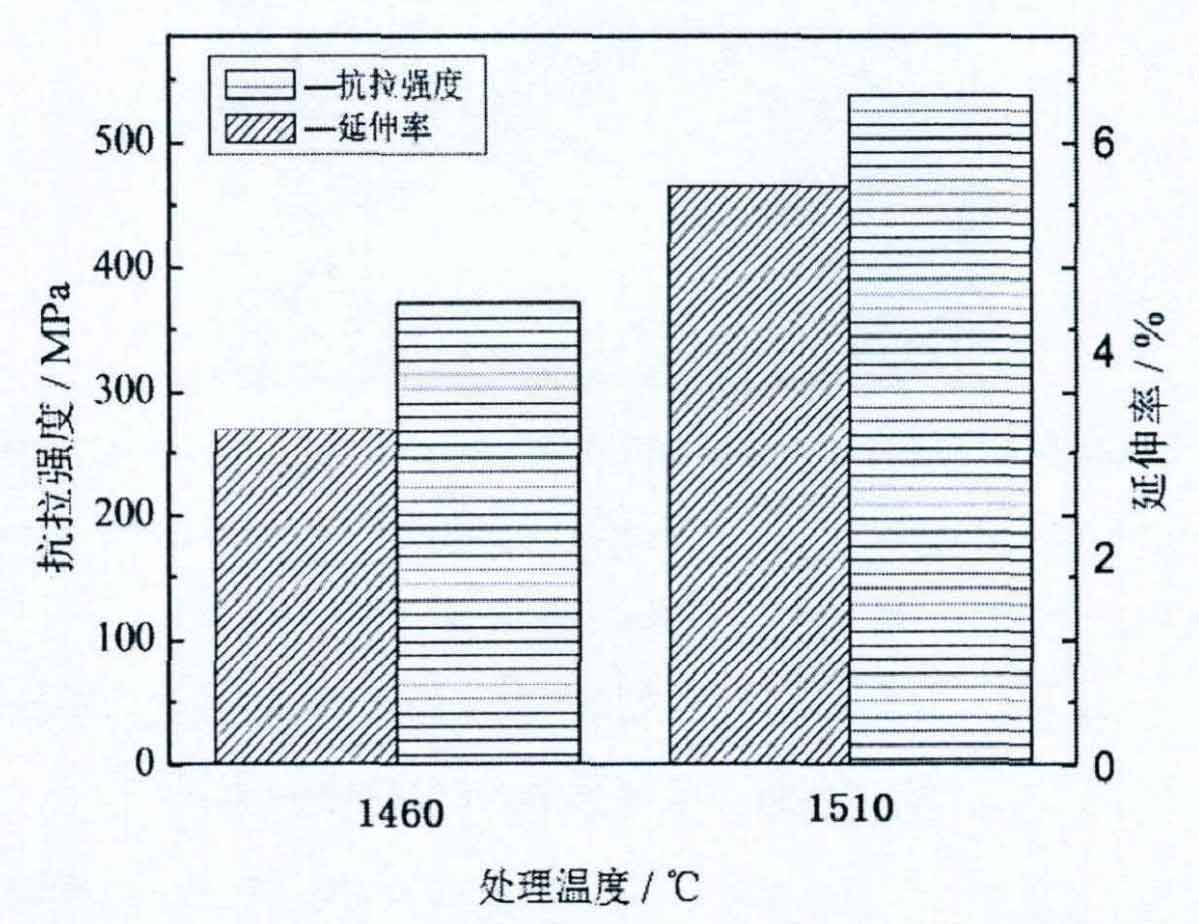

Figure 1 shows the mechanical properties of as cast ductile iron. It can be seen from Figure 1 that the tensile strength and elongation of nodular cast iron treated at 1510 ° C are higher. It can be seen from the above analysis that in the nodular cast iron with a treatment temperature of 1510 ° C, the nodularization rate of nodular cast iron is high, and the graphite balls are mostly spherical. In addition, the nodular cast iron matrix contains more pearlite and a small amount of carbides, and the pearlite matrix has high strength. In addition, the carbides contained in the cast iron further hinder the deformation of the metal. Therefore, Ductile iron has high tensile strength and elongation. In the nodular cast iron with a treatment temperature of 1460 ° C, the existence of agglomerate and flocculent graphite reduces the spheroidization rate of nodular cast iron, increases the cleavage effect on the matrix structure, and reduces the utilization rate of matrix strength. Therefore, the tensile strength of nodular cast iron is low.

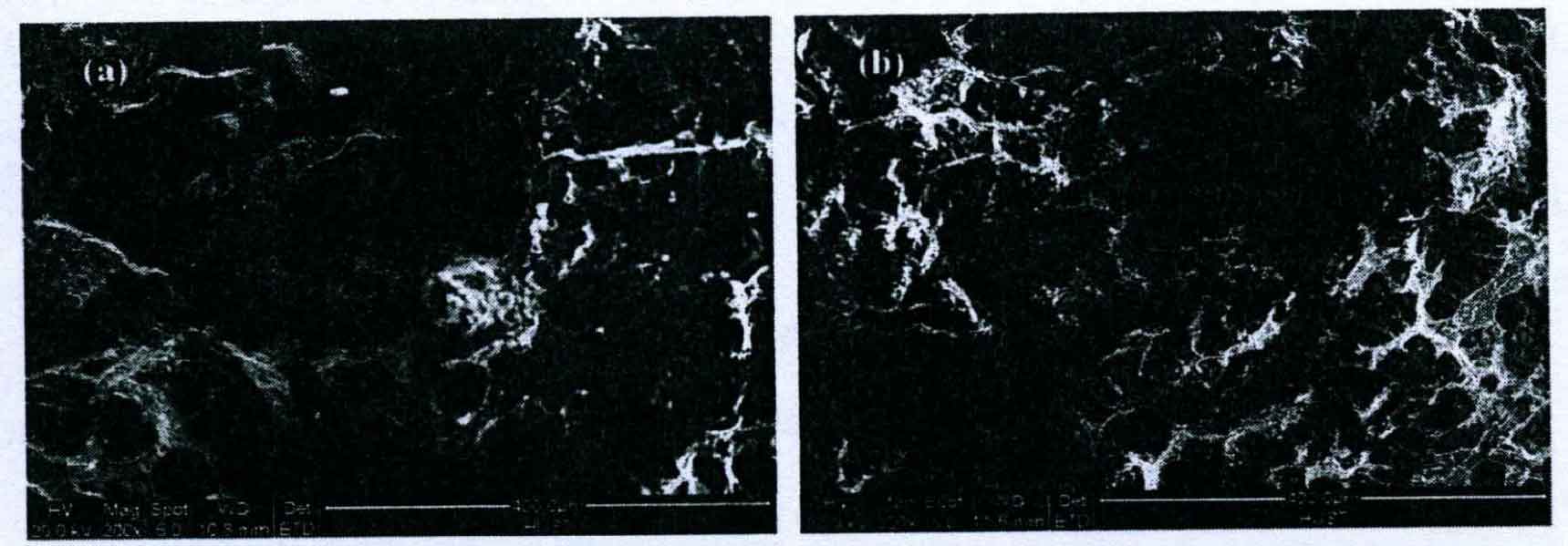

In order to investigate the fracture mechanism of nodular cast iron, the fracture morphology of nodular cast iron was studied and analyzed. Figure 2 shows the fracture morphology of as cast ductile iron.

It can be seen from figure 2A that the fracture surface of nodular cast iron with a treatment temperature of 1510 ° C has a river pattern of cleavage steps, which belongs to brittle fracture. However, there is a large distance between Shishu and tearing edge, which hinders the crack propagation during deformation and improves the tensile strength and elongation of nodular cast iron. Although there are many dimples on the fracture surface of nodular graphite cast iron treated at 1460 ° C, a large number of disorderly graphite are distributed on the fracture surface. These graphites weaken the utilization of matrix strength and reduce the tensile strength and elongation of nodular cast iron. Therefore, the tensile strength and elongation of nodular cast iron are low.