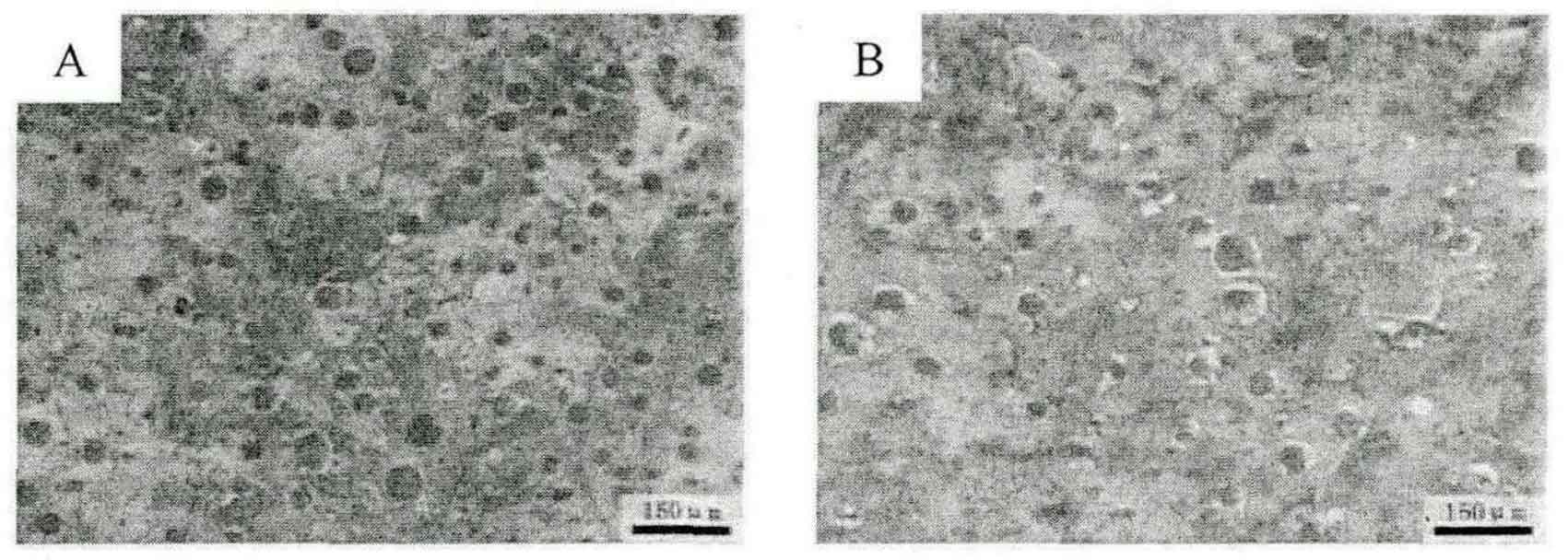

Using 340mm feldspar ink probe, add ultrasound into the spheroidizing bag, the action time is 1min, and the indication of current and output power are 1.5A and 80% respectively: then pour the molten iron into two cavities, continue to add ultrasonic treatment in one of them for 18S, and the current and output power are 1a and 50% respectively. The test piece with ultrasonic wave applied twice is a, the test piece with ultrasonic wave applied only once in the spheroidizing package is B, and the test piece without spheroidizing treatment is e. The gold phase is shown in the figure.

From the metallographic diagram, it can be clearly observed that the number of graphite balls in specimen a is significantly increased compared with specimen B. after calculation, the field of view range is 1.08mm2 as shown in the above figure. Calculate the number of graphite in multiple fields of view of specimens a and B, and take the average value. There are 93 graphite balls in specimen a, 41 graphite balls in specimen B and about 40 graphite balls in specimen a

1.8 times in B. At the same time, observe the shape of the graphite ball. The size of the graphite ball in a is all hooked, and the rounding rate is high. Using the software, it is analyzed that the ferrite content in a is 7.24%, the ferrite content in B is 10.60%, and the ferrite content in a is less than that in B. According to the metallographic test standard of nodular cast iron, the graphite in a is classified as grade 1 and that in B is grade 3; Ferrite is classified according to the ferrite map. Ferrite A is 5B and ferrite B is 10A. The specific ferrite content and mechanical properties are shown in the table. By testing the mechanical properties of the two specimens, it is found that there is little difference in tensile strength, impact toughness and hardness. The elongation of specimen a after fracture after two ultrasonic treatments is slightly larger than that of specimen B.

| Test piece No | Number of graphite balls | Ferrite content /% | Tensile strength / MPa | Elongation after fracture /% | Impact toughness / J | Hardness / HB |

| A | 93 | 7.24 | 823 | 7.3 | 34.3 | 245 |

| B | 41 | 10.60 | 822 | 6.6 | 35.7 | 249 |

Similarly, after ultrasonic treatment for 1min in the spheroidizing process, but a applied ultrasonic treatment for 18S in the mold, resulting in the difference of microstructure and mechanical properties between the two. Ultrasonic is applied in the solidification process. The ultrasonic cavitation effect and thermal effect make the nodular iron castings cool slowly. In this way, the carbon poor layer in the embassy body and the carbon in the solution can be balanced conditionally through diffusion. The carbon poor layer around the nodular graphite rarely appears. At this time, the graphite ball will grow freely alone in the flame for a long time, Therefore, the graphite in the is uniform in size, high in roundness and low in ferrite content.