In the process of gray cast iron cutting experiment, the measurement cycle is very short, the cutting length of the blade is small, and the impact on the tool wear is ignored. The experiment uses the installation of the same tool to complete the cutting force experiment with the same processing parameters. In the cutting process, the tool is not changed or reinstalled, so as to avoid the impact of the change of tool reinstallation angle on the cutting force in the same group of machining experiments. Cutting depth: 2.5 mm. The experimental data are substituted into the stress-strain relationship obtained by calibration, and the calculated three-dimensional gray cast iron cutting force is based on the formula:

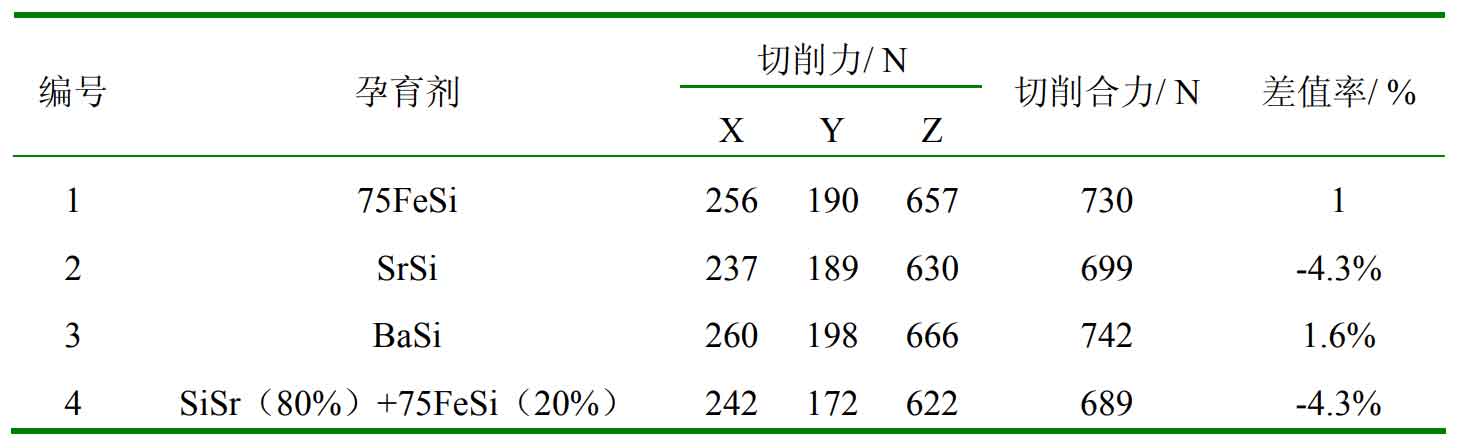

Calculate the three-way resultant force. The change of cutting force of the test sample is shown in the table.

It can be seen from the table that when the cutting depth is 2.5 mm, the three-dimensional cutting force and cutting force of the gray cast iron sample inoculated with basi are the largest, and the total force reaches 742 n; The cutting force of the sample treated by composite inoculation is the smallest. Under the same strength, the three-dimensional cutting force and cutting force of the gray cast iron sample inoculated with basi are significantly higher than those inoculated with SRSI. In the cutting process of the sample, the cutting force directly affects the generation of cutting heat, and further affects the tool wear and durability. Therefore, the cutting force can directly reflect the difficulty of cutting the material to a great extent. The smaller the cutting force is, the smaller the tool wear is, and the better the cutting performance of the material is.