Abstract

The engine cylinder block, a critical component in automotive engines, has faced persistent challenges related to shrinkage porosity and leakage defects, particularly in high-stress regions such as bolt holes and thick-walled sections. This study investigates the root causes of these defects in HT300 engine cylinder blocks and proposes targeted solutions, including adjustments to molten iron chemistry, charge ratio optimization, application of tellurium powder coatings, and structural redesign. Through these interventions, the scrap rate due to leakage decreased from 6.3% to 0.8%, demonstrating significant improvements in production efficiency and product reliability.

1. Introduction

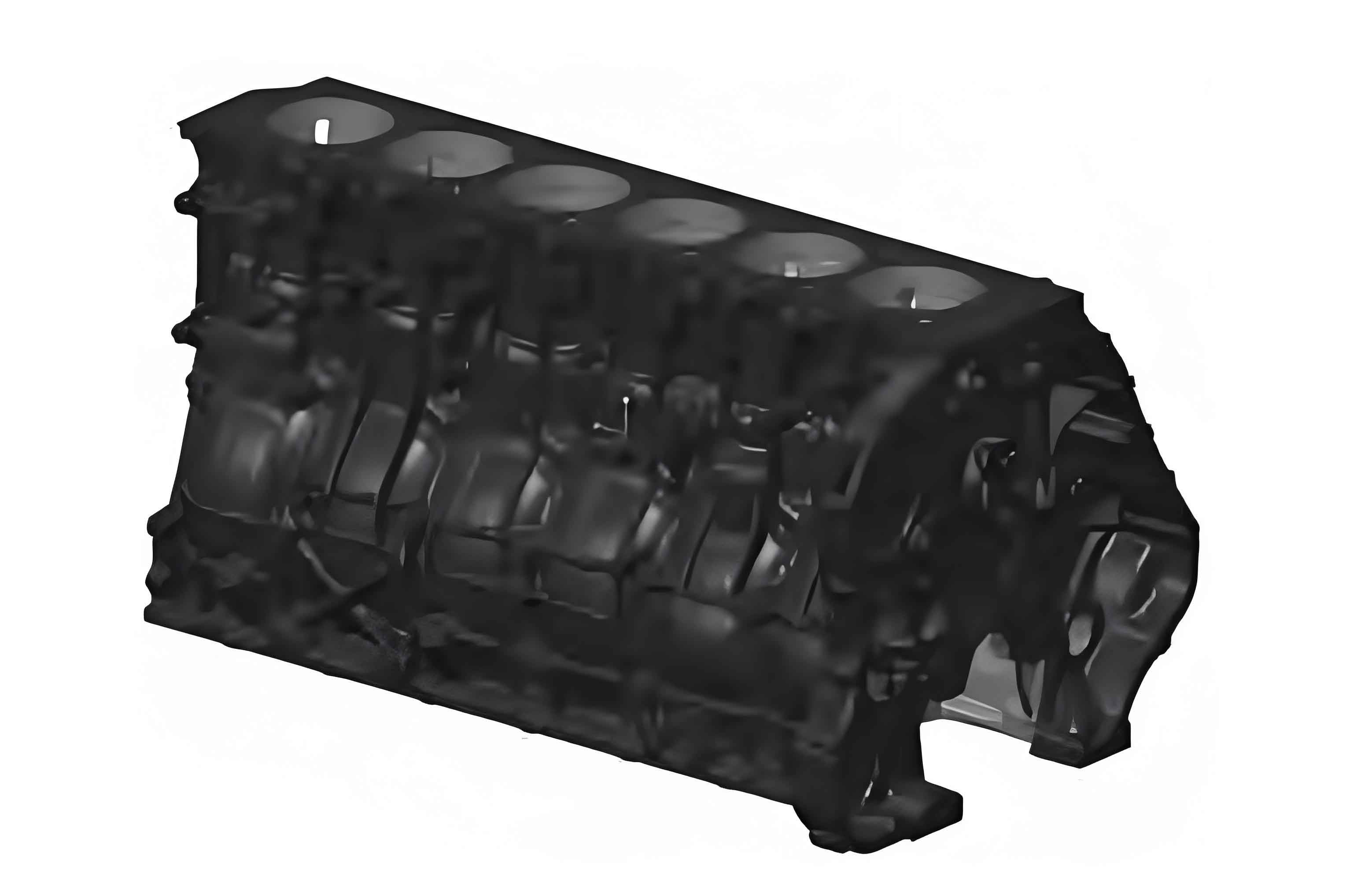

The engine cylinder block serves as the backbone of internal combustion engines, requiring exceptional mechanical strength, thermal stability, and dimensional precision. With the automotive industry’s shift toward lightweight designs and higher performance standards, manufacturers have progressively reduced wall thicknesses (from 5 mm to 3.5 mm) and upgraded materials from HT250 to HT300. However, these advancements inadvertently increased susceptibility to shrinkage porosity—a defect characterized by microvoids formed during solidification, leading to gas leakage in critical zones like bolt holes and oil passages.

This paper details a systematic approach to mitigating shrinkage-related defects in engine cylinder blocks, combining material science, process optimization, and design enhancements.

2. Problem Description

2.1 Defect Manifestation

Leakage defects in engine cylinder blocks were primarily observed in two scenarios:

- Bolt Hole Leakage: Shrinkage porosity near bolt holes caused unintended connections between high-pressure oil channels and bolt threads (Fig. 1a).

- Wall Penetration Leakage: Shrinkage cavities breached the outer walls of the cylinder block, linking internal passages to the exterior (Fig. 1b).

These defects compromised engine integrity during bench testing and real-world operation, leading to increased scrap rates.

2.2 Technical Specifications

Key requirements for the HT300 engine cylinder block included:

- Wall thickness: 3.8 mm (minimum 3.5 mm).

- Sand core process: Triethylamine cold-box cores (excluding water jacket cores).

- Melting: Electric furnace with semi-automatic pouring.

- Metallurgical standards:

- Graphite structure: ≥70% Type A, ≤20% Type B.

- Pearlite content: ≥90%.

- Mechanical properties: Tensile strength ≥220 MPa, hardness 187–241 HBW.

A summary of chemical composition requirements is provided in Table 1.

Table 1: Chemical Composition of HT300 Engine Cylinder Block (Mass Fraction, %)

| Element | C | Si | Mn | Cu | Cr | Sn | S | P |

|---|---|---|---|---|---|---|---|---|

| Range | 3.28–3.30 | 1.6–1.7 | 0.70–0.90 | 0.5–0.7 | 0.30–0.35 | 0.04–0.07 | 0.08–0.12 | ≤0.08 |

3. Root Cause Analysis

3.1 Shrinkage Porosity Mechanisms

Shrinkage porosity in engine cylinder blocks arises due to:

- Extended Solidification Time: Thick sections (e.g., bolt holes) solidify last, creating regions where molten metal cannot adequately compensate for contraction.

- Insufficient Feeding: Poor fluidity of molten iron exacerbates void formation.

- Alloying Element Imbalance: Excessive chromium (Cr) or titanium (Ti) increases shrinkage tendency.

3.2 Charge Ratio Impact

Increased scrap steel usage (30–70% of charge) introduced trace elements like Ti, Pb, and V, which destabilized the microstructure. Trends in scrap steel impurities are summarized below:

Table 2: Trace Element Content in Scrap Steel (2022–2023)

| Element | 2022 Avg. (%) | 2023 Avg. (%) | Specification Limit (%) |

|---|---|---|---|

| Ti | 0.024 | 0.042 | <0.03 |

| Pb | <0.005 | <0.005 | <0.005 |

| V | <0.02 | <0.02 | <0.02 |

Ti content exceeded specifications by 40% in 2023, directly correlating with higher shrinkage porosity rates.

4. Improvement Strategies

4.1 Molten Iron Chemistry Optimization

Adjustments to carbon equivalent (CE) and alloying elements enhanced fluidity and reduced shrinkage:

- CE Formula:CE=%C+%Si+%P3CE=%C+3%Si+%PCE was increased from 3.85 to 3.92 by raising C (3.28–3.32%) and Si (1.65–1.70%).

- Chromium Reduction: Cr content lowered to 0.25–0.30% to minimize white structure formation.

Table 3: Adjusted Chemical Composition (Mass Fraction, %)

| Element | Original Range | Revised Range |

|---|---|---|

| C | 3.28–3.30 | 3.30–3.32 |

| Si | 1.60–1.70 | 1.65–1.70 |

| Cr | 0.30–0.35 | 0.25–0.30 |

4.2 Charge Ratio Adjustment

To counteract scrap steel impurities:

- Increased Pig Iron: +800 kg per batch.

- Reduced Scrap Steel: -800 kg per batch.

Table 4: Revised Charge Ratio (Mass Fraction, %)

| Material | Original | Revised |

|---|---|---|

| Pig Iron | 0–25 | 25–35 |

| Scrap Steel | 30–70 | 20–60 |

| Gray Iron Returns | 30–70 | 30–70 |

4.3 Tellurium Powder Coating

Tellurium (Te), a volatile element, acted as a “chemical chill” by:

- Rapidly evaporating during solidification, creating a dense ferritic layer.

- Reducing thermal gradients in critical zones (e.g., bolt holes).

Coating was applied locally to water jacket cores (Fig. 6), targeting high-risk areas.

4.4 Structural Redesign

Wall thickness near leakage-prone regions was increased by 15–20%, and bolt holes were repositioned farther from water cavities (Figs. 7–8).

5. Results and Discussion

5.1 Defect Rate Reduction

Post-implementation data showed dramatic improvements:

Table 5: Leakage Defect Rates Before and After Improvements

| Cylinder Block Series | Initial Scrap Rate (%) | Final Scrap Rate (%) |

|---|---|---|

| 493 Series | 6.3 | 0.8 |

| PUMA Series | 10.29 | 0.89 |

5.2 Mechanical Performance

All enhancements maintained or exceeded HT300 standards:

- Tensile strength: 225–240 MPa.

- Hardness: 190–235 HBW.

6. Conclusion

Through a holistic approach combining material science, process control, and design innovation, shrinkage porosity defects in engine cylinder blocks were effectively mitigated. Key takeaways include:

- Chemistry Adjustments: Higher CE and reduced Cr minimized shrinkage.

- Charge Management: Balancing scrap steel impurities stabilized microstructure.

- Innovative Coatings: Tellurium coatings provided localized chilling.

- Structural Optimization: Thickened walls reduced leakage risks.

These strategies not only resolved leakage issues but also established a framework for addressing similar defects in future engine cylinder block designs.