Casting quality is a critical factor in ensuring the performance and reliability of cast components. Shrinkage defects can compromise the integrity and dimensional accuracy of castings, leading to functional issues and increased scrap rates. By implementing effective shrinkage control strategies and optimizing the casting process, foundries can enhance casting quality. This article explores various techniques and approaches to achieve shrinkage control and process optimization for improved casting quality.

- Gating and Riser Design: Proper gating and riser design are crucial for effective shrinkage control. The design should ensure a smooth and controlled flow of molten metal into the mold cavity, minimizing the risk of localized solidification and shrinkage defects. Additionally, well-designed risers can act as reservoirs, providing a continuous supply of molten metal to compensate for solidification shrinkage.

- Cooling and Solidification Control: Optimizing the cooling and solidification process is essential for minimizing shrinkage defects. Controlling the cooling rate, mold temperature, and heat transfer mechanisms can influence the solidification behavior and reduce the occurrence of shrinkage. Advanced cooling techniques, such as the use of chill plates or controlled cooling environments, can help achieve uniform solidification and mitigate shrinkage.

- Alloy Selection and Modification: The choice of alloy composition significantly impacts shrinkage behavior. Selecting an alloy with appropriate solidification characteristics, such as a narrower freezing range, can minimize shrinkage defects. Alloy modification, such as the addition of grain refiners or inoculants, can refine the microstructure and improve the feeding characteristics, reducing the potential for shrinkage defects.

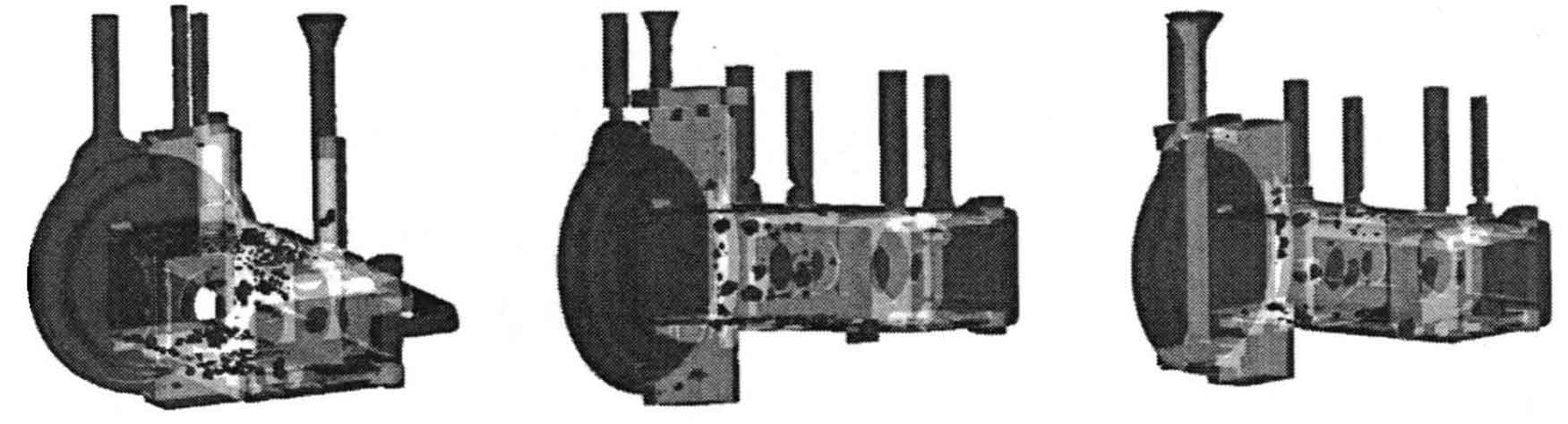

- Process Parameters Optimization: Fine-tuning the process parameters, including pouring temperature, mold preheating, and solidification time, can have a significant impact on shrinkage control. Computer-aided casting simulation can assist in optimizing these parameters to achieve desirable solidification behavior and minimize shrinkage defects. By simulating the casting process, potential shrinkage areas can be identified, allowing for proactive adjustments to reduce their occurrence.

- Rigorous Quality Control: Implementing a robust quality control system is vital for detecting and addressing shrinkage defects. Non-destructive testing methods, such as visual inspection, ultrasonic testing, or X-ray examination, can identify internal defects caused by shrinkage. Strict adherence to quality control protocols ensures that castings with shrinkage defects are identified and rectified before further processing or assembly.

- Continuous Improvement and Knowledge Sharing: Encouraging a culture of continuous improvement and knowledge sharing within the foundry is essential for enhancing casting quality. Regular evaluation of casting processes, analysis of shrinkage defects, and feedback loops from the shop floor can lead to the identification of improvement opportunities. Sharing best practices and lessons learned among the team fosters a collective understanding of shrinkage control and process optimization.

By adopting a holistic approach that combines effective shrinkage control strategies with process optimization, foundries can significantly enhance casting quality. Minimizing shrinkage defects ensures dimensional accuracy, structural integrity, and reliable performance of cast components across various industries. Continuous research, innovation, and collaboration within the foundry industry will drive further advancements in shrinkage control techniques and process optimization, ultimately improving casting quality and customer satisfaction.