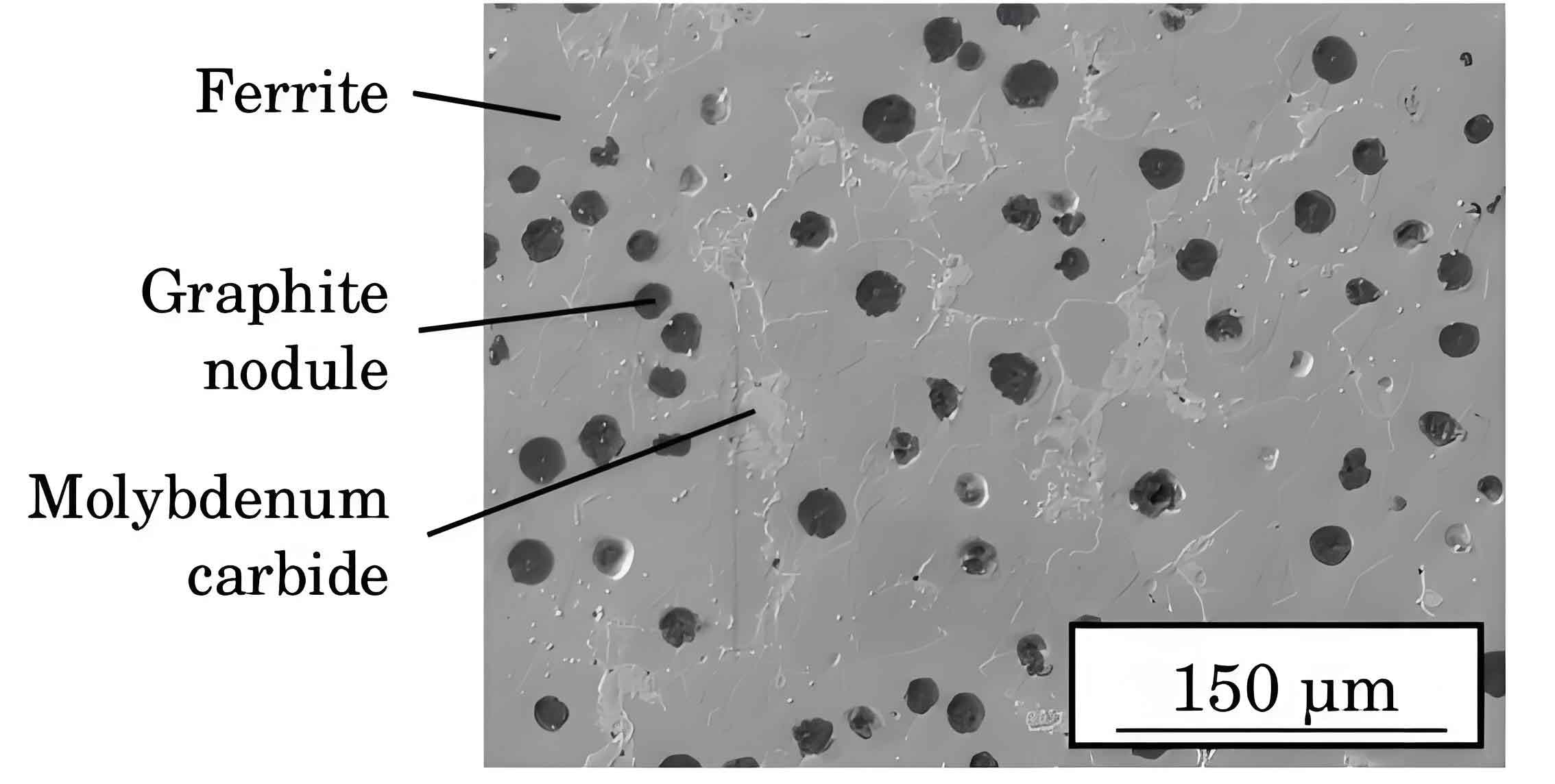

Spheroidal graphite iron castings are renowned for its excellent mechanical properties, including high strength, ductility, and wear resistance. However, to meet the increasingly stringent demands of modern engineering applications, these properties often need further enhancement. Advanced heat treatment techniques offer a powerful approach to optimizing the mechanical properties of spheroidal graphite iron castings. This article explores various heat treatment methods, their effects on the microstructure, and the resulting improvements in mechanical performance. Comprehensive tables and lists are included to enhance understanding.

Introduction

Heat treatment is a critical process in the production of spheroidal graphite iron castings, allowing for the adjustment of mechanical properties to meet specific application requirements. By altering the microstructure through controlled heating and cooling cycles, properties such as strength, hardness, ductility, and wear resistance can be significantly improved. This article delves into advanced heat treatment techniques, including annealing, normalizing, quenching, tempering, and austempering, and their impact on spheroidal graphite iron castings.

Advanced Heat Treatment Techniques

- Annealing:

- Purpose: To soften the material, improve machinability, and relieve internal stresses.

- Process: Heating to a specific temperature, holding for a period, and then slow cooling.

- Effect: Results in a ferritic matrix with improved ductility and reduced hardness.

- Normalizing:

- Purpose: To refine the microstructure and enhance mechanical properties.

- Process: Heating above the critical temperature, holding, and air cooling.

- Effect: Produces a pearlitic matrix, increasing strength and hardness while maintaining adequate ductility.

- Quenching:

- Purpose: To increase hardness and strength.

- Process: Rapid cooling from a high temperature by immersion in water, oil, or air.

- Effect: Creates a martensitic structure, significantly increasing hardness and tensile strength but reducing ductility.

- Tempering:

- Purpose: To reduce brittleness after quenching and improve toughness.

- Process: Reheating quenched material to a lower temperature and then cooling.

- Effect: Adjusts the martensitic structure to achieve a balance between hardness and toughness.

- Austempering:

- Purpose: To produce a bainitic microstructure for an optimal balance of strength, toughness, and wear resistance.

- Process: Heating to the austenitizing temperature, followed by rapid cooling to a lower temperature and holding until bainite forms.

- Effect: Results in a bainitic structure, combining high strength and toughness with excellent wear resistance.

Table: Advanced Heat Treatment Techniques and Their Effects

| Technique | Purpose | Process | Effect |

|---|---|---|---|

| Annealing | Soften material, improve machinability | Heating, holding, slow cooling | Ferritic matrix, improved ductility, reduced hardness |

| Normalizing | Refine microstructure, enhance properties | Heating above critical temperature, air cooling | Pearlitic matrix, increased strength and hardness, good ductility |

| Quenching | Increase hardness and strength | Rapid cooling (water, oil, air) | Martensitic structure, high hardness, high strength, low ductility |

| Tempering | Reduce brittleness, improve toughness | Reheating quenched material, then cooling | Adjusted martensitic structure, balanced hardness and toughness |

| Austempering | Optimal balance of properties | Heating, rapid cooling, holding at lower temperature | Bainitic structure, high strength, toughness, wear resistance |

Microstructural Changes Induced by Heat Treatment

- Ferritic Matrix: Soft and ductile, achieved through annealing. Suitable for applications requiring high ductility and machinability.

- Pearlitic Matrix: Strong and hard, formed by normalizing. Ideal for applications demanding high strength and wear resistance.

- Martensitic Structure: Extremely hard and strong, created by quenching. Best for applications where high wear resistance and strength are critical, though ductility is sacrificed.

- Tempered Martensite: Balanced hardness and toughness, produced by tempering quenched material. Suitable for components that need to withstand both high loads and impacts.

- Bainitic Structure: Combines high strength, toughness, and wear resistance, resulting from austempering. Ideal for components exposed to dynamic and abrasive conditions.

List: Microstructural Outcomes of Heat Treatment

- Ferritic Matrix:

- Soft and ductile

- Achieved through annealing

- Pearlitic Matrix:

- Strong and hard

- Formed by normalizing

- Martensitic Structure:

- Extremely hard and strong

- Created by quenching

- Tempered Martensite:

- Balanced hardness and toughness

- Produced by tempering

- Bainitic Structure:

- High strength, toughness, and wear resistance

- Resulting from austempering

Enhancements in Mechanical Properties

- Strength and Hardness:

- Normalizing and Quenching: Both processes significantly increase the strength and hardness of spheroidal graphite iron castings, making it suitable for high-load and wear-resistant applications.

- Austempering: Offers a unique combination of high strength and toughness.

- Ductility and Toughness:

- Annealing: Enhances ductility, making the material more flexible and easier to machine.

- Tempering: Improves toughness after quenching, reducing brittleness and enhancing impact resistance.

- Austempering: Provides superior toughness along with high strength.

- Wear Resistance:

- Quenching and Austempering: Both processes improve wear resistance, essential for components subject to abrasive conditions.

- Impact Resistance:

- Tempering and Austempering: Both enhance the material’s ability to absorb shocks and impacts without fracturing.

Table: Mechanical Property Enhancements Through Heat Treatment

| Property | Heat Treatment Techniques | Resulting Enhancement |

|---|---|---|

| Strength and Hardness | Normalizing, Quenching, Austempering | Increased strength and hardness, suitable for high-load applications |

| Ductility and Toughness | Annealing, Tempering, Austempering | Enhanced ductility and toughness, reduced brittleness |

| Wear Resistance | Quenching, Austempering | Improved wear resistance, suitable for abrasive conditions |

| Impact Resistance | Tempering, Austempering | Enhanced ability to absorb shocks and impacts |

Practical Applications of Heat Treated Spheroidal Graphite Iron Castings

- Automotive Industry:

- Engine Components: High strength and wear resistance through quenching and tempering.

- Suspension Parts: Enhanced toughness via austempering.

- Heavy Machinery:

- Construction Equipment: Balanced strength and ductility from normalizing.

- Mining Equipment: Superior wear resistance and impact toughness through austempering.

- Pipeline and Fittings:

- Pumps and Valves: Improved corrosion resistance and toughness through tempering.

- Pipeline Joints: High strength and flexibility via annealing and normalizing.

- Industrial Tools:

- Cutting Tools: High hardness and wear resistance from quenching.

- Molds and Dies: Balanced properties through tempering and austempering.

Table: Applications of Heat Treated Spheroidal Graphite Iron Castings

| Industry | Components | Heat Treatment Method | Resulting Properties |

|---|---|---|---|

| Automotive | Engine components, Suspension parts | Quenching, Tempering, Austempering | High strength, wear resistance, toughness |

| Heavy Machinery | Construction, Mining equipment | Normalizing, Austempering | Balanced strength and ductility, superior wear resistance |

| Pipeline and Fittings | Pumps, Valves, Pipeline joints | Tempering, Annealing, Normalizing | Improved corrosion resistance, toughness, flexibility |

| Industrial Tools | Cutting tools, Molds, Dies | Quenching, Tempering, Austempering | High hardness, wear resistance, balanced properties |

Future Trends in Heat Treatment of Spheroidal Graphite Iron Castings

- Advanced Monitoring and Control:

- IoT and AI Integration: Real-time monitoring and control of heat treatment processes to ensure consistency and precision.

- Predictive Analytics: Using data analytics to predict and prevent defects, enhancing overall quality.

- Environmentally Friendly Processes:

- Energy Efficiency: Development of energy-efficient heating and cooling methods to reduce environmental impact.

- Sustainable Practices: Increased focus on using eco-friendly quenching media and reducing emissions.

- Innovative Heat Treatment Techniques:

- Laser and Induction Hardening: Localized heat treatment methods for precise property enhancement.

- Cryogenic Treatment: Enhancing wear resistance and toughness by deep freezing components after heat treatment.

- Material-Specific Optimization:

- Custom Heat Treatment Cycles: Tailoring heat treatment cycles to specific spheroidal graphite iron castings compositions for optimal performance.

List: Future Trends in Heat Treatment of Spheroidal Graphite Iron Castings

- Advanced Monitoring and Control:

- IoT and AI integration

- Predictive analytics

- Environmentally Friendly Processes:

- Energy efficiency

- Sustainable practices

- Innovative Heat Treatment Techniques:

- Laser and induction hardening

- Cryogenic treatment

- Material-Specific Optimization:

- Custom heat treatment cycles

Conclusion

Advanced heat treatment techniques play a crucial role in enhancing the mechanical properties of spheroidal graphite iron castings. By carefully selecting and controlling these processes, it is possible to achieve a desired balance of strength, hardness, ductility, and wear resistance tailored to specific industrial applications. As the industry continues to evolve with advancements in monitoring, environmentally friendly practices, and innovative techniques, the potential for further improvements in spheroidal graphite iron castings’s performance remains significant, ensuring its continued relevance in high-performance engineering applications.