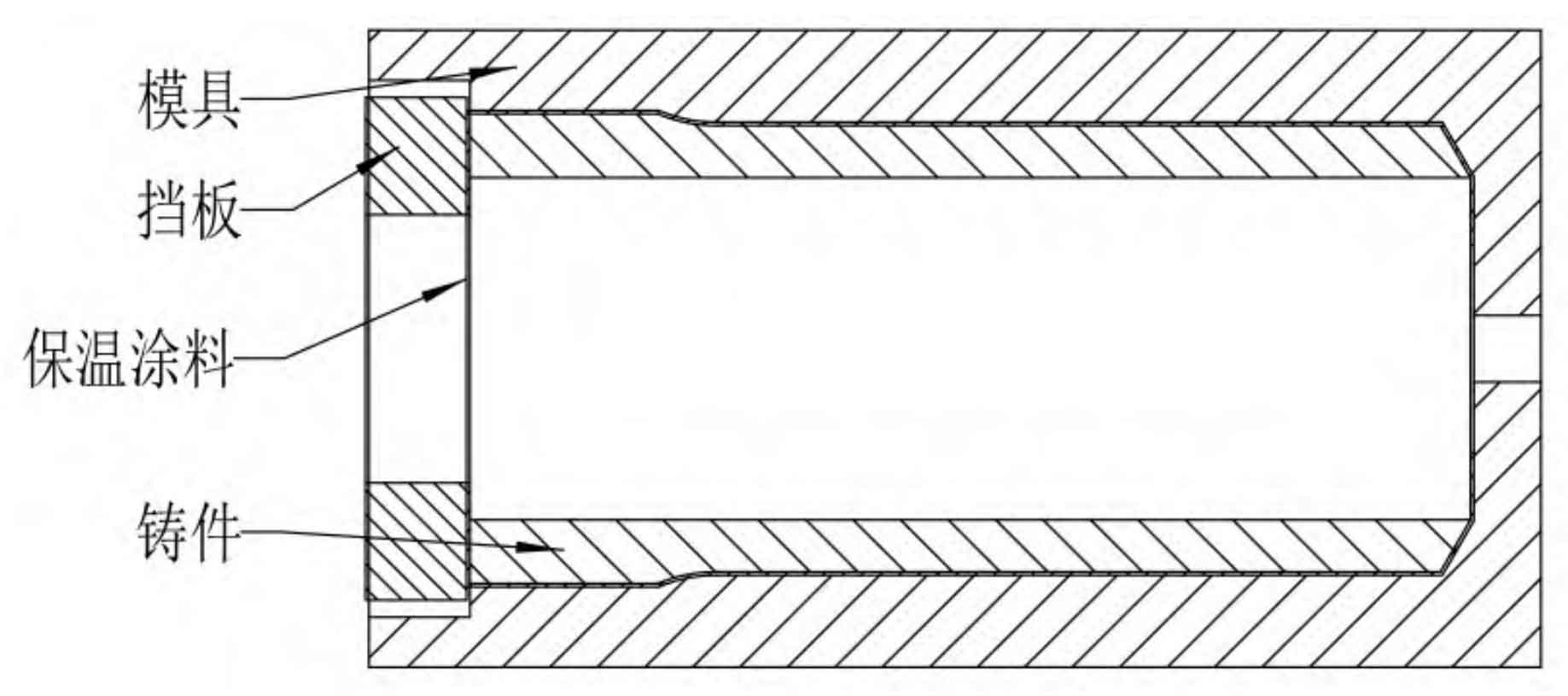

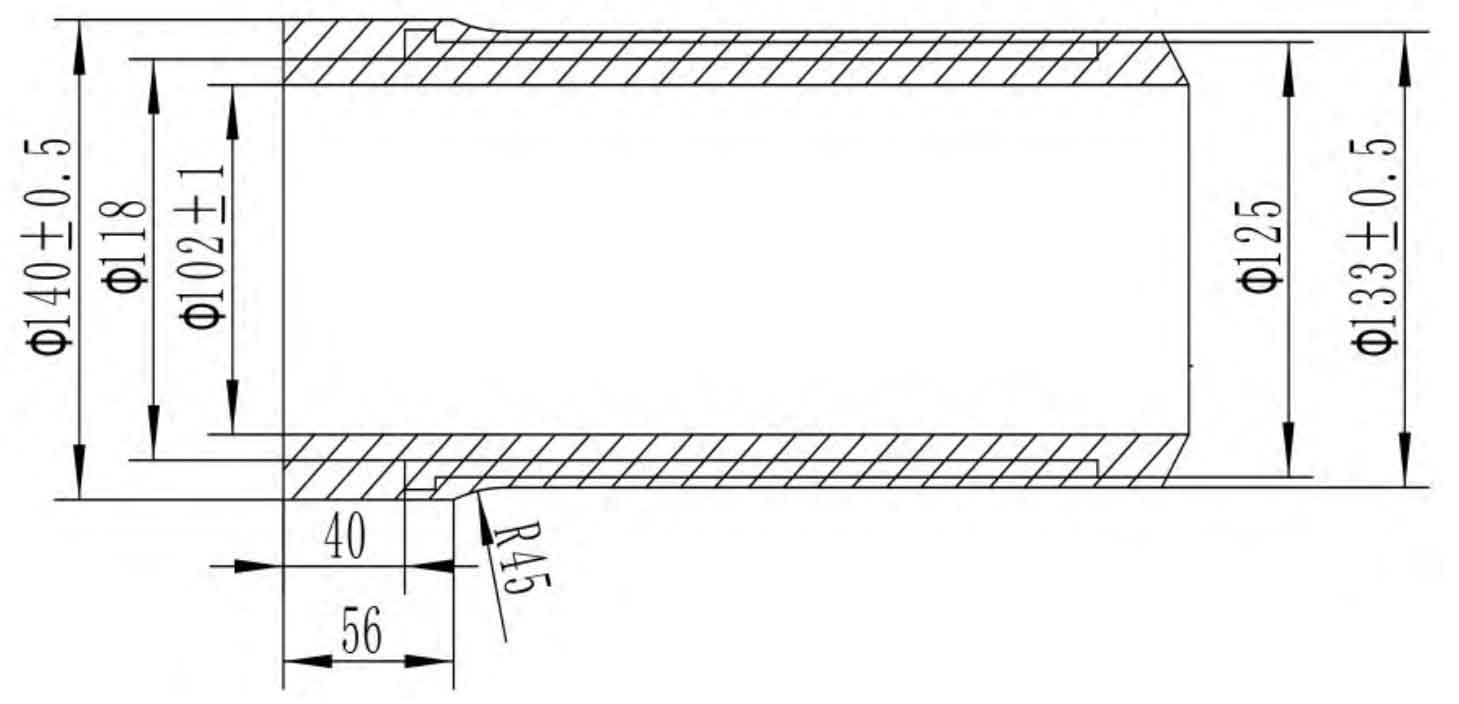

The assembly drawing of casting and mold is shown in Figure 1. The maximum diameter of casting Φ 140mm, length 298mm, maximum wall thickness 19mm. The distribution diagram of casting blank and machining allowance is shown in Figure 2. The unilateral machining allowance of inner hole is 7-9mm, the machining allowance of pouring end is 40mm, and the machining allowance of tail end is 20mm.

The unstructured tetrahedral grid is used to divide the mold, baffle, casting and insulation coating, increase the grid density of insulation coating and casting, and increase the grid size of mold and baffle to reduce the calculation amount. The pouring position is set on the inner surface of the casting, with the number of surface grids of 99812 and the number of body grids of 719843. The grid division results are shown in Figure 3.