Mold design plays a crucial role in the casting process, including the control of casting shrinkage. The design of the mold directly influences the solidification and cooling behavior of the molten metal, which in turn affects the shrinkage behavior of the final casting. In this article, we explore the effects of mold design on casting shrinkage behavior and how it can be optimized to minimize shrinkage defects.

- Mold Material Selection: The choice of mold material can impact the heat transfer characteristics and thermal conductivity, which influence the cooling rate of the molten metal. Different mold materials have varying coefficients of thermal expansion, which can affect the dimensional changes and shrinkage behavior of the casting. Proper selection of mold material, considering the specific casting alloy and desired casting properties, is essential to achieve optimal shrinkage control.

- Gating System Design: The design of the gating system, including the sprue, runners, and gates, plays a significant role in controlling the flow of molten metal into the mold cavity. Improper gating system design can lead to uneven filling and cooling, resulting in non-uniform solidification and increased shrinkage. The use of appropriate gating designs, such as tapered runners and properly sized gates, promotes uniform flow and solidification, minimizing shrinkage defects.

- Venting: Effective venting is crucial to allow the escape of air and gases from the mold cavity during casting. Inadequate venting can lead to the entrapment of gases, resulting in porosity and shrinkage defects. Proper placement and sizing of vents based on the mold design and the specific casting geometry help ensure efficient venting and minimize the risk of shrinkage.

- Mold Cooling System: The cooling system in the mold design influences the cooling rate of the casting. Proper cooling is essential to achieve controlled solidification and minimize shrinkage. The placement and design of cooling channels, including their size, shape, and spacing, need to be optimized to ensure uniform cooling and minimize thermal gradients. Uniform cooling helps in achieving uniform solidification and reduces the likelihood of shrinkage defects.

- Mold Coating: The application of mold coatings can help control the heat transfer and solidification behavior of the casting. Mold coatings provide a thermal barrier and influence the cooling rate during solidification. By selecting the appropriate mold coating and optimizing its application, the cooling rate and shrinkage behavior can be controlled.

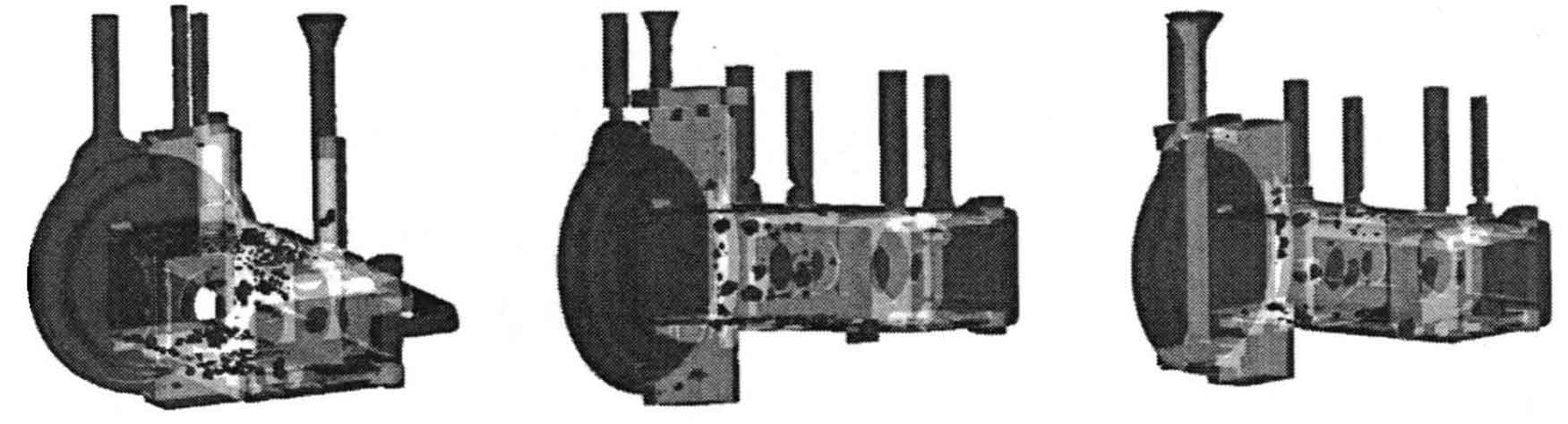

- Simulation and Optimization: Advanced casting simulation software can be utilized to analyze and optimize the mold design for shrinkage control. These simulations allow for the prediction of shrinkage patterns and identification of potential areas of concern. By conducting virtual experiments and making design adjustments based on simulation results, mold designs can be optimized to minimize shrinkage defects.

Proper mold design is critical in achieving optimal shrinkage control in the casting process. By considering factors such as mold material selection, gating system design, venting, mold cooling system, mold coating, and utilizing advanced simulation tools, foundries can optimize the mold design to minimize shrinkage defects. Effective shrinkage control in the mold design ensures the production of high-quality castings with the desired dimensional accuracy and integrity.