In the process of investigation and research, after certain search, it is found that there is no special arrangement of relevant data sets in some professional and large data websites, and because it is difficult to obtain the data of excavator bucket on site, the data sets used are mainly taken by using the excavator bucket model made by ourselves, plus the data sets collected and arranged by some websites sharing pictures at home and abroad.

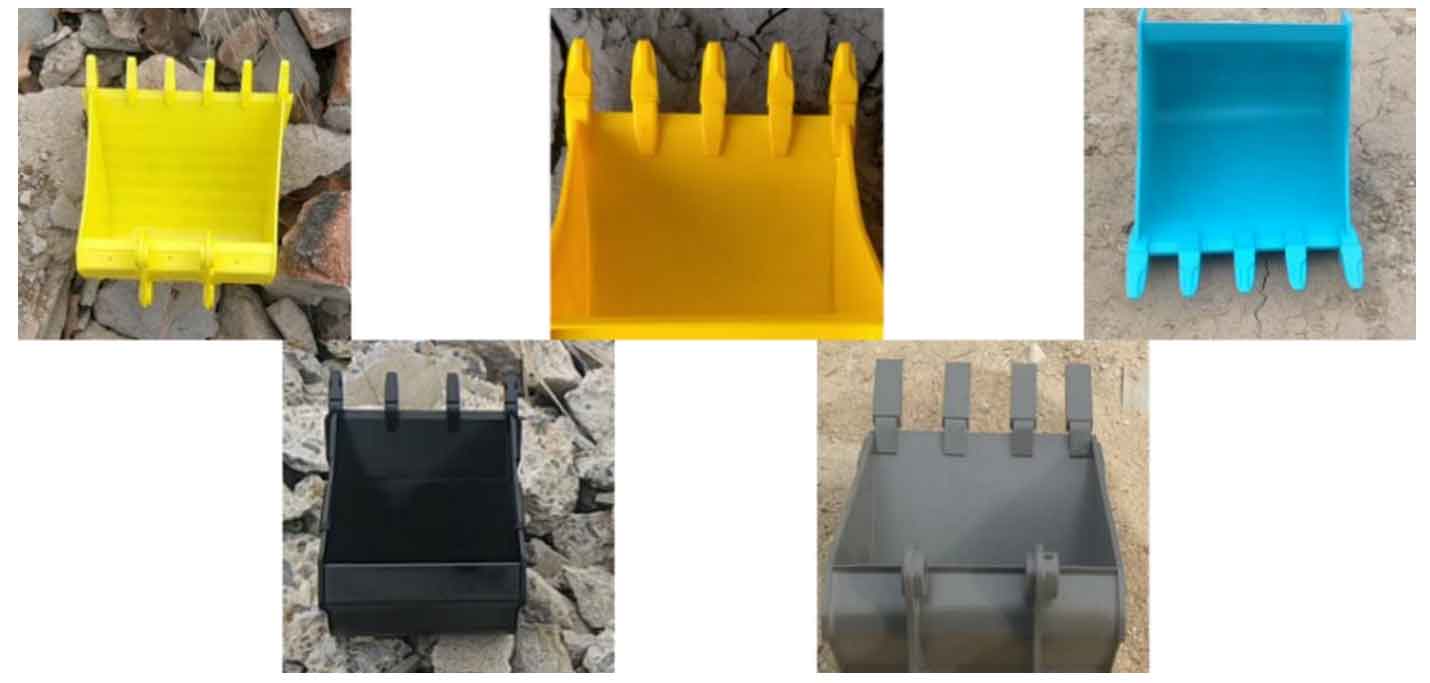

In this paper, the model bucket as the acquisition object is generated by 3D printing, and polished, painted and colored according to the actual excavator bucket. Due to the limited experimental conditions and personal ability, five kinds of excavator buckets as shown in Figure 1 are used as the acquisition object to make the model bucket data set.

Since the subsequent algorithm involves the determination of the position of the bucket teeth of the excavator bucket fault, this paper considers the possible fault position of the bucket teeth when collecting the data set, and uses one of the excavator buckets for display.

As shown in Figure 2, it is a black excavator bucket with four bucket teeth. If the excavator bucket fails to have one bucket tooth, there are four possible failure positions, as shown in Figure 2 (a); If two bucket teeth of the excavator bucket fail, there are six possible failure positions, as shown in Figure 2 (b).

Considering that there are few cases where more than two bucket teeth of the excavator bucket fail at the same time, this data only includes three cases: normal excavator bucket, excavator bucket with one bucket tooth and excavator bucket with two bucket teeth.

In order to make the model bucket more close to the actual working condition when shooting, and to reduce the over fitting during network training, so that the parameters trained by the network are more robust. In the process of data collection, this paper selects different times and places to enrich the background of the excavator bucket, fully considers the possible shooting angles, and appropriately uses sand, stone particles and soil to cover and pollute the excavator bucket to varying degrees. The data display is shown in Figure 3.