In the production of high-integrity castings, particularly for internal combustion engines, achieving soundness free from defects is a paramount challenge. Among the various defects encountered, porosity in casting stands out as one of the most prevalent and economically significant. The formation of pores within the solidified metal can severely compromise the mechanical properties, pressure tightness, and overall service life of the component. Over the years, as the demand for lighter, more powerful, and more efficient engines has grown, the complexity of castings like cylinder blocks and heads has increased dramatically. This complexity, characterized by intricate internal cavities necessitating numerous sand cores, inherently elevates the risk of gas-related defects. This article details a comprehensive approach developed through practical experience to mitigate porosity in casting, focusing primarily on the strategic design and assurance of the exhaust system for core gases and mold gases.

The battle against porosity in casting begins with understanding its genesis. Gas pores can be classified into several categories based on their source: entrapped air from turbulent filling, gases evolved from the decomposition of mold and core binders (invasive porosity), gases precipitated from the solidifying metal itself, and pores formed from metallurgical reactions. For complex, cored castings such as cylinder blocks and heads, the predominant villain is often invasive porosity. This occurs when gases generated from the heated sand cores cannot escape rapidly enough into the mold atmosphere and are instead forced into the solidifying metal. The pressure buildup within the core, \( P_{core} \), must overcome the metallostatic pressure from the liquid metal, \( P_{metal} = \rho g h \), and the ambient pressure in the mold, \( P_{atm} \), to infiltrate. If venting is inadequate, gas bubbles penetrate the metal-mold interface, leading to defects. The fundamental relationship can be simplified as:

$$ P_{core} > P_{metal} + P_{atm} + \gamma / r $$

Where \( \gamma \) is the surface tension and \( r \) is the pore radius at the interface. Effective venting keeps \( P_{core} \) low, preventing this inequality from being satisfied and thus preventing porosity in casting.

The severity of this problem was starkly evident in the production of a family of diesel engine components. Despite using advanced molding lines (high-pressure green sand) and core-making processes (cold-box and shell), the reject rate due to porosity in casting reached alarming levels, at times exceeding 10% of total production. Statistical analysis revealed that porosity alone accounted for nearly 70% of all defective parts. The defects were localized in predictable yet problematic areas: on the walls of critical bore diameters and large flat surfaces on cylinder blocks, and on the top decks of cylinder heads. This localization pointed directly to areas where cores were heavily encapsulated and where venting paths were likely compromised. This situation necessitated a systematic and multi-faceted intervention focused on exhaust system optimization.

Core Venting: The First Line of Defense Against Porosity in Casting

The core is the primary source of gas. During pour, organic binders thermally decompose, releasing large volumes of gas. A core without an escape route for this gas becomes a pressurized bomb waiting to force its contents into the liquid metal, causing porosity in casting. Therefore, the design and execution of core venting are critical. Our strategy involved three complementary layers.

1. Integrated Vent Channels in Core Design: The most effective method is to design the exhaust path into the core itself from the outset. For major cores, such as the cylinder bore cores in a block or the water jacket core in a head, a dedicated vent channel is incorporated along the core’s axis or through its substantial sections. This channel must terminate at a core print (core head) that is designed to be large enough to provide sufficient venting area. The required vent area \( A_{vent} \) can be estimated based on the core’s volume, binder content, and pour time to ensure gas can escape without significant pressure buildup:

$$ A_{vent} \propto \frac{V_{core} \cdot G}{t_{pour}} $$

Where \( V_{core} \) is the core volume, \( G \) is the specific gas generation, and \( t_{pour} \) is the pouring time. This vent channel in the core must align perfectly with a corresponding channel in the mold, created by a vent pin or a raised feature on the pattern plate, ensuring a continuous open path to the exterior.

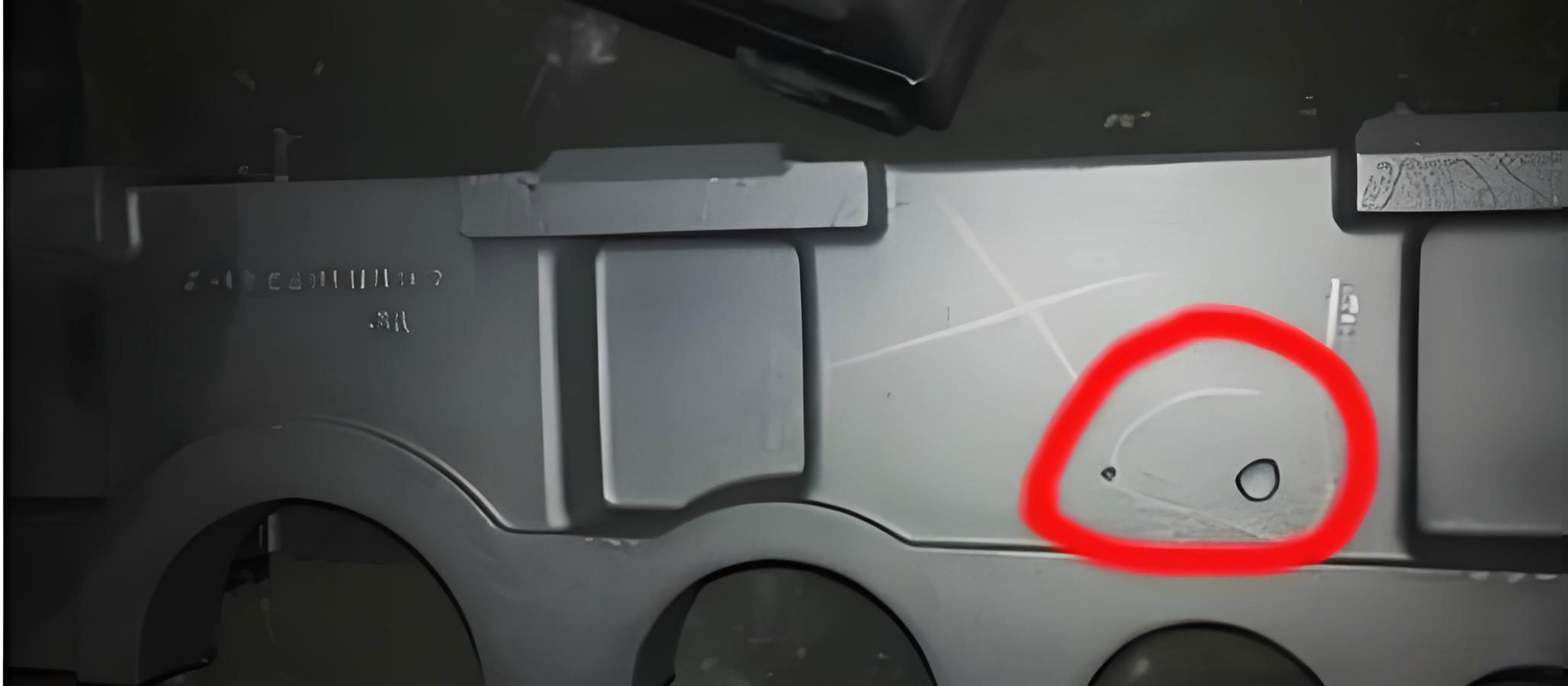

2. Supplemental Drilled Vent Holes: Not all venting needs can be pre-designed into the core tooling. Many cores have natural features that can be integrated into a vent network. After core production, strategic drilling of vent holes connects internal core cavities to core prints. Typical locations include:

- Core prints for crankshaft bays, water jackets, and intake/exhaust ports.

- Through existing core openings or “windows” designed for cleaning.

- From thick sections of the core towards a print.

This manual operation creates a secondary venting network, significantly reducing the distance gas must travel within the core sand, thereby lowering the core gas pressure and the risk of porosity in casting.

3. Sealing and Isventing at Core Assemblies: A common failure point occurs where multiple cores interface or where a core print meets the mold. Liquid metal can penetrate these joints, sealing off vent paths prematurely. To prevent this, we employ high-temperature flexible seals, such as ceramic fiber or asbestos-free gaskets, placed at critical core print interfaces. These gaskets allow gas to pass through their porous structure but block the flow of molten metal, keeping the vent channel open throughout the pour. This simple measure is exceptionally effective in preventing the early blockage of vents, a major contributor to localized porosity in casting.

| Strategy | Method | Key Principle | Effect on Core Gas Pressure (\( P_{core} \)) |

|---|---|---|---|

| Integrated Vent Design | Pre-formed channel in core tooling. | Provides a primary, low-resistance path for gas escape. | Dramatically reduces initial and sustained pressure. |

| Supplemental Drilling | Manual drilling post-coremaking. | Creates a networked vent system, shortening gas travel distance. | Lowers localized pressure in complex core regions. |

| Interface Sealing | Application of high-temp gaskets at prints. | Prevents metal ingress and early vent blockage. | Maintains vent pathway integrity, preventing sudden pressure spikes. |

Mold Cavity Exhaust: The Final Escape Route

While core venting channels gas into the mold cavity, the mold itself must provide an unimpeded route for this gas, along with air displaced by the metal, to exit to the atmosphere. An inadequate mold exhaust system can lead to back-pressure, slowing filling and increasing the chance of gas entrapment and porosity in casting. Our mold exhaust strategy is multi-pronged.

1. Utilization of Feeders (Risers) for Exhaust: Feeders, primarily placed to compensate for solidification shrinkage, serve a dual purpose as excellent exhaust points. They are naturally located at the top of the mold cavity (the highest point where gas collects). Ensuring they are open and of sufficient volume allows them to act as reservoirs for gas and initial, possibly colder, metal. The timing of gas flow can be conceptualized, where the gas removal rate through the feeder should ideally match or exceed the gas generation rate from the cores during the critical filling and initial solidification phase.

2. Strategic Use of Vent Pins and Vent Sheets: Direct venting through the mold cope is essential. This is achieved using:

Vent Pins: Small-diameter wires or rods set in the pattern plate. They create fine holes in the sand cope over areas like bolt bosses, thin ribs, or high points distant from feeders. These pins allow gas to escape but are small enough to prevent metal penetration.

Vent Sheets: Thin, flat pieces attached to the pattern. They create narrow, elongated vents over larger flat areas or thick sections. These serve not only to vent gas but also to act as chillers, promoting directional solidification which can help prevent shrinkage-related micro-porosity in casting.

The placement logic is summarized by the rule: vent the farthest point from the ingate, vent the highest points, and vent areas above large cores.

3. Wash Sealing of Print Cavities: A practical measure taken during mold closing involves manually applying a refractory paste (mold wash sealant) around the exposed openings of core vent channels on the mold surface. This seals the sand around the vent exit, preventing molten metal from “running down” the vent hole from the cope side during pouring—a phenomenon known as down-running or metal penetration into vents, which would instantly block the exhaust path and guarantee porosity in casting in the associated region.

Quantitative Impact and System Integration

The implementation of this holistic exhaust system philosophy—encompassing both core and mold venting—transformed the quality outcome. The previously isolated treatments of core design and mold pattern layout were integrated into a single system design review process. Every core was analyzed for its gas generation potential and a venting plan was documented. Every mold pattern was reviewed for vent pin and sheet placement, ensuring they aligned with core vent exits and cavity hotspots.

The result was a drastic reduction in the defect rate attributed to porosity in casting. The reject rate fell from the initial crisis level of over 10% to a consistently maintained level below 2%. This improvement underscores a critical principle: in the fight against invasive porosity in casting, managing gas pressure through engineered escape routes is more effective than solely trying to reduce gas generation. The system’s effectiveness can be modeled by considering the overall flow resistance of the exhaust path. The total pressure drop \( \Delta P_{total} \) from the core interior to the atmosphere must be minimized:

$$ \Delta P_{total} = \Delta P_{core\_sand} + \Delta P_{vent\_channel} + \Delta P_{mold\_sand} $$

Where each term represents the pressure drop through the respective medium. Our strategies aimed to reduce \( \Delta P_{core\_sand} \) (via drilled vents), optimize \( \Delta P_{vent\_channel} \) (via designed channels and sealing), and minimize \( \Delta P_{mold\_sand} \) (via direct vent pins and open feeders).

| Metric | Before Optimization | After Optimization | Improvement / Notes |

|---|---|---|---|

| Reject Rate due to Porosity | >10% | <2% | ~80% reduction in porosity-related scrap. |

| Porosity as % of Total Defects | ~70% | ~25% | Porosity is no longer the dominant defect. |

| Typical Defect Locations | Bore walls, top decks, large flats. | Random, minor occurrences. | Systematic localization eliminated. |

| Key Corrective Actions | Reactive: Adjusting pours, coating. | Proactive: System design, process control. | Shift from process tweaking to engineered solution. |

In conclusion, controlling porosity in casting, especially for intricate engine components, is a battle won through the meticulous design and safeguarding of exhaust pathways. It requires viewing the mold-core assembly not just as a shape-forming entity, but as a dynamic pneumatic system. By proactively designing vent channels into cores, augmenting them with drilled vents, protecting vent exits with seals, and complementing this with aggressive mold cavity venting via pins, sheets, and feeders, the gas generated during the pour can be safely and efficiently managed. This systematic approach transforms porosity in casting from a frequent, costly problem into a well-controlled aspect of the production process, ensuring the reliability and performance of the final cast component. The principles detailed here, while honed on specific engine castings, are universally applicable to any complex, cored casting where porosity in casting poses a significant quality threat.