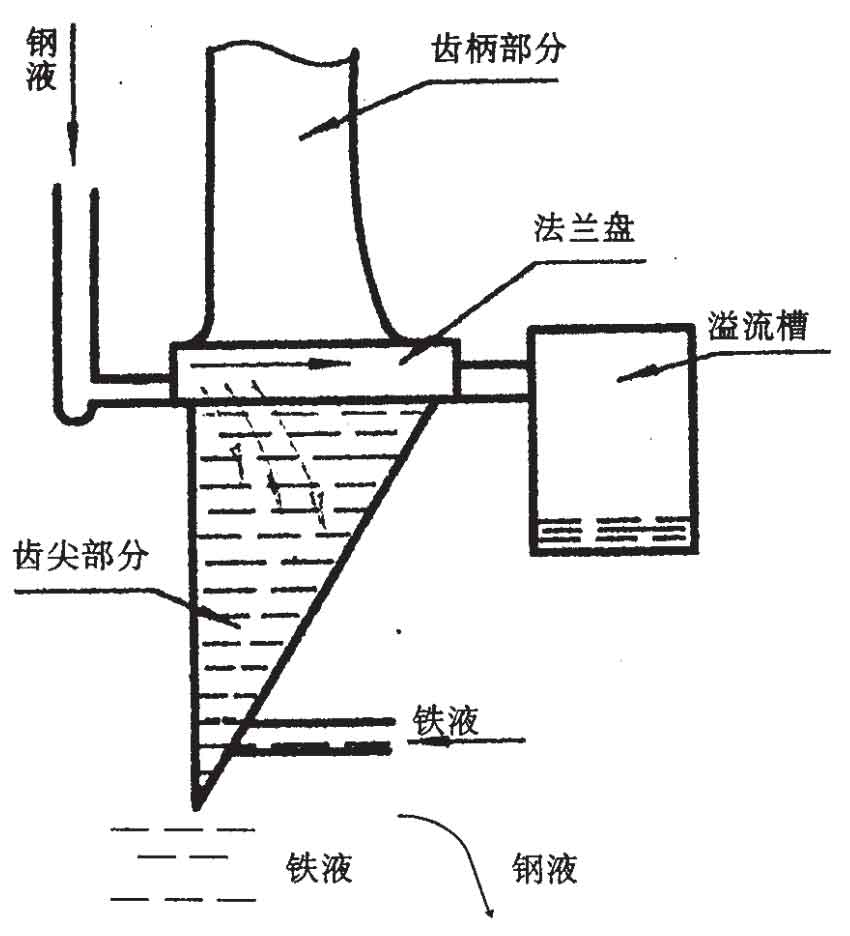

(1) When the liquid level of molten iron with viscosity V1 is high, the flow state of molten steel into “molten iron” when pouring into the model is shown in Figure 1. After pouring, the molten steel flows smoothly and clockwise. Within 2-3s, the mixing height is about 70mm.

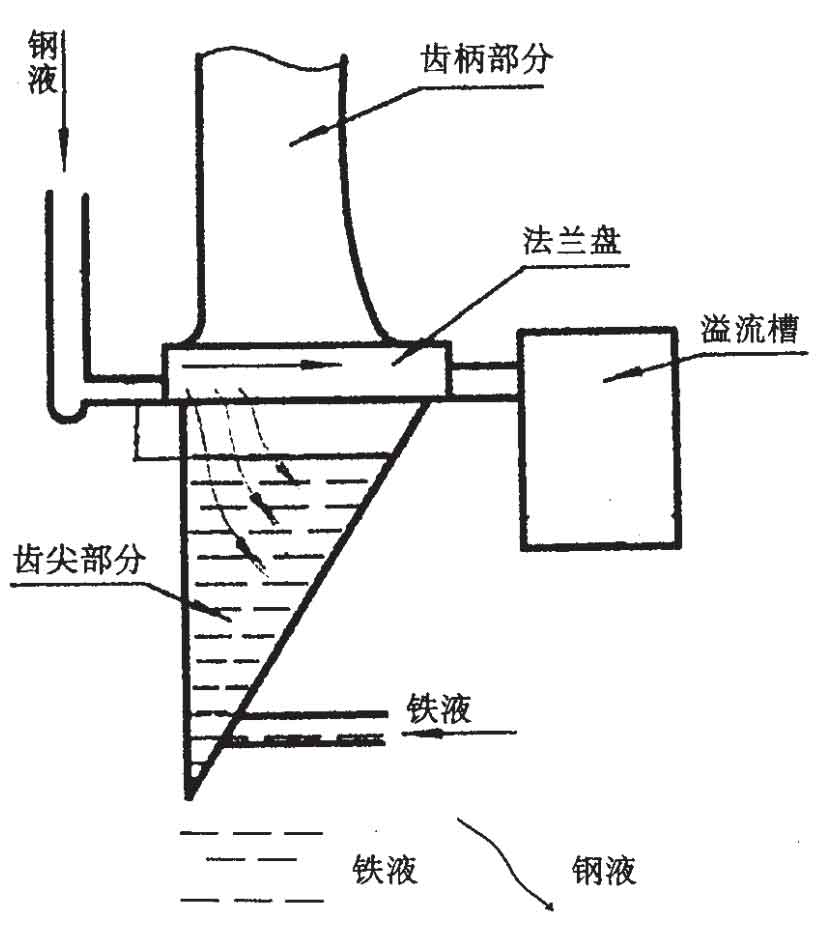

(2) When the liquid iron level with viscosity V1 is low; The molten steel poured almost falls along the left edge of the bucket teeth and flows counterclockwise in the molten iron. The flow state is shown in Figure 2.

The two liquids quickly mixed to the tip of the tooth tip, and the mixing was serious, almost along the whole height of the tooth tip (200mm).

(3) When the liquid level of molten iron with viscosity V2 is high, the molten steel pouring is relatively stable and flows clockwise. The situation is similar to the first one above, but there is no serious mixing in the case of 1, and the mixing depth is about 40mm.

(4) When the liquid iron with viscosity of V2 has a low liquid level, the flow state of liquid steel is similar to the second case above, but the mixing degree is not as deep as 2, which is about 45-50mm.

(5) When the liquid iron with viscosity of V3 has a high liquid level, the flow state of liquid steel is similar to that in cases 1 and 3 above, and the mixing depth is about 30mm.

(6) When the liquid iron with viscosity of V3 has a low liquid level, the flow state of liquid steel is similar to that in cases 1 and 3 above, and the mixing depth is about 40mm.