1. Fatigue load loading

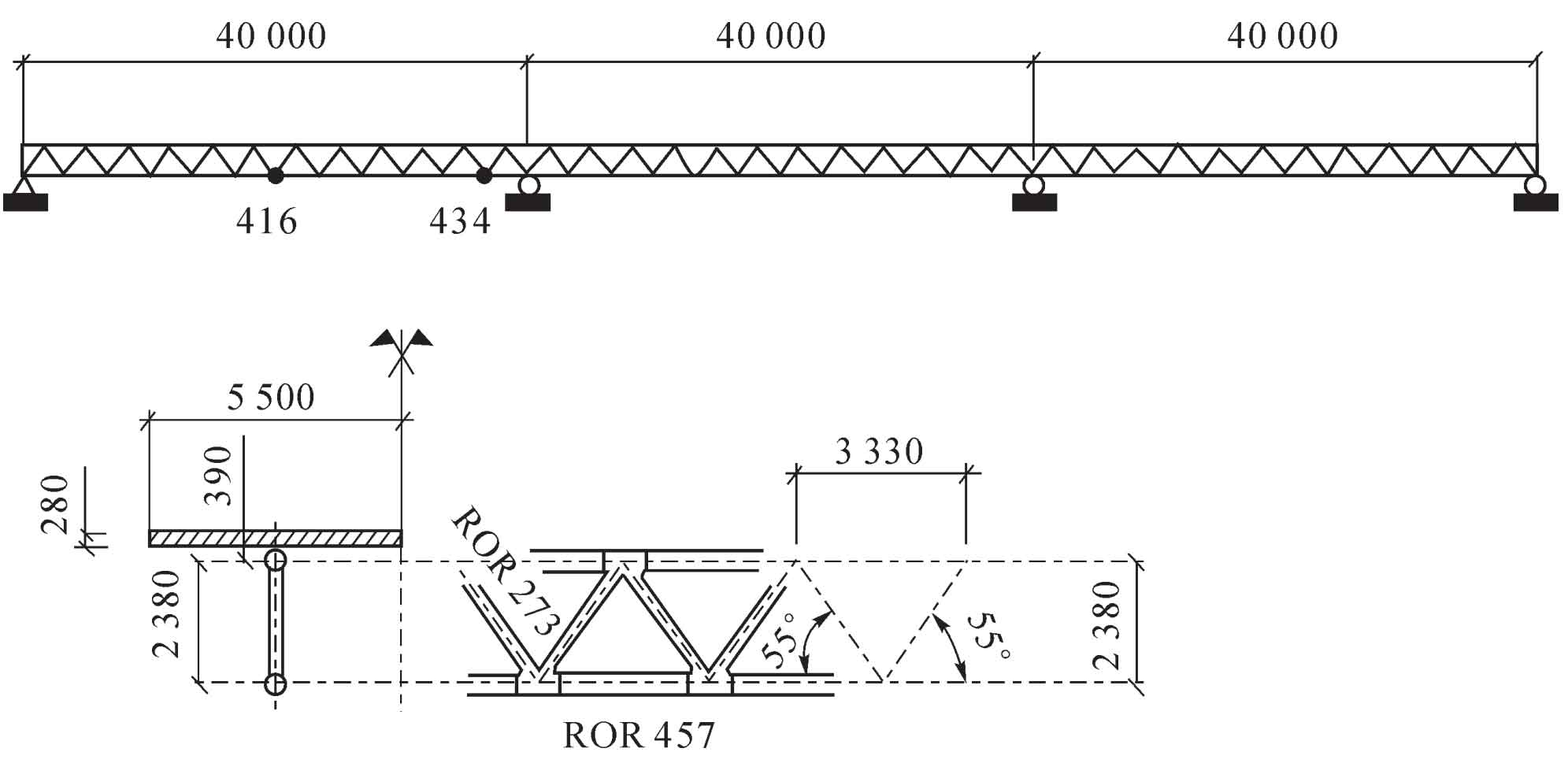

In order to effectively test the influence of multiple casting defects on the fatigue performance of cast steel joints, the equal amplitude fatigue load, Fmin = 200 kn and Fmax = 1000 kn, which are concentrated loads, is applied to the integral pipe truss model. The average stress and stress amplitude at the defect location in eight pipe truss models with casting defects.

2. Experimental results

It can be seen that based on the values of stress amplitude and average stress at different defect positions in various models, the corresponding safety factors can be calculated respectively through the formula.

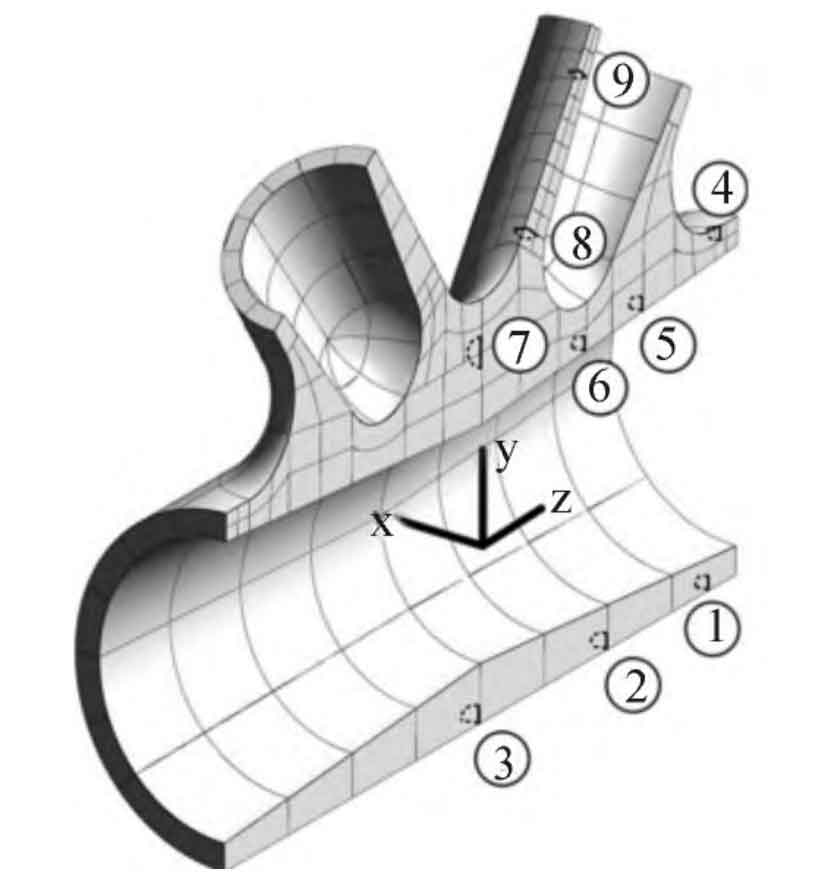

It can be seen that models 1, 2 and 4 have secondary casting defects at position ①. In addition, they all have many other secondary casting defects at the same time. Under the same load conditions, the safety factors of models 1, 2 and 4 at position ① are 1.27, 1.29 and 1.26 respectively. However, there is only one secondary casting defect at position ① in model 6, and the safety factor is 1.52, which shows that when the distribution of casting defects is different, there will be great differences in the fatigue performance of cast steel joints. At the same time, compared with cast steel joints with multiple casting defects, cast steel joints with single casting defects have better fatigue performance.

In addition, models 1 and 2 are secondary casting defects, and model 5 is tertiary casting defects. However, the overall safety factors of models 1 and 2 are 3.46 and 3.54, while the overall safety factor of model 5 is higher, reaching 4.38. It can be seen that the fatigue performance of cast steel joints is not necessarily proportional to the quality grade, that is, the current evaluation method is not completely accurate. This is because, to a certain extent, compared with the size of casting defects, the location distribution of casting defects has a greater impact on the fatigue performance of cast steel joints. At the same time, compared with models 1 and 2, the overall safety factor of model 4 is smaller, only 3.36. This is because there are more defect locations in model 4, which shows that to a certain extent, the more casting defects are distributed in cast steel joints, the worse their fatigue performance is.

Through the above analysis, it can be concluded that the safety evaluation method of cast steel joints should consider the distribution of multiple defects at the same time.