The formation of cast steel joints has experienced two stages: mold filling and solidification. Macroscopically, it mainly involves three physical phenomena: flow, cooling and shrinkage. In the process of mold filling, the flow field, temperature field and concentration field change at the same time. Solidification is accompanied by the change of temperature field, and there are phenomena such as inter dendritic convection and shrinkage. Shrinkage leads to the change of stress field. The main casting defects related to flow are insufficient pouring, cold shut, air hole and slag inclusion. The distribution of temperature field formed in mold filling is directly related to the subsequent solidification and cooling process; The distribution of concentration field formed in mold filling is related to the segregation and microstructure heterogeneity formed by subsequent cooling and solidification.

The change of temperature field and shrinkage during solidification are the main causes of shrinkage porosity, and the direct causes of micro shrinkage are inter dendrite convection and dendrite shrinkage. Hot cracking and cold cracking should be attributed to the change of stress field.

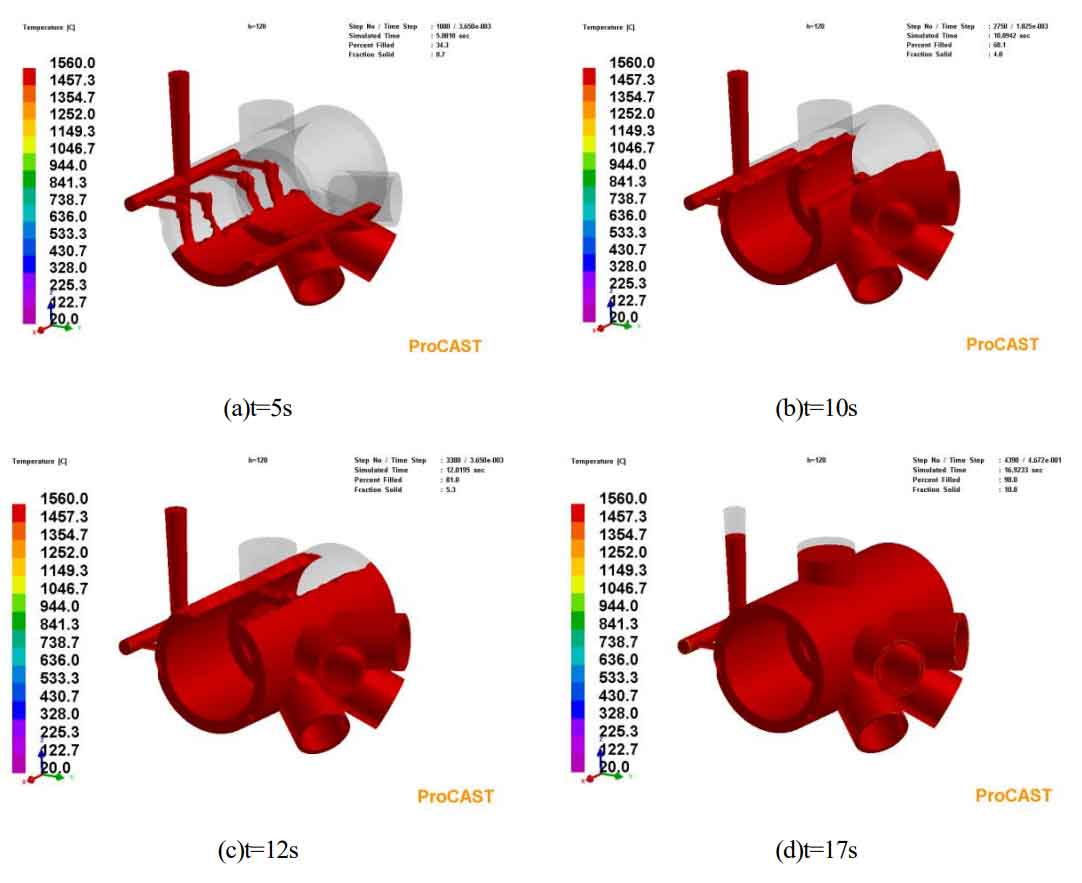

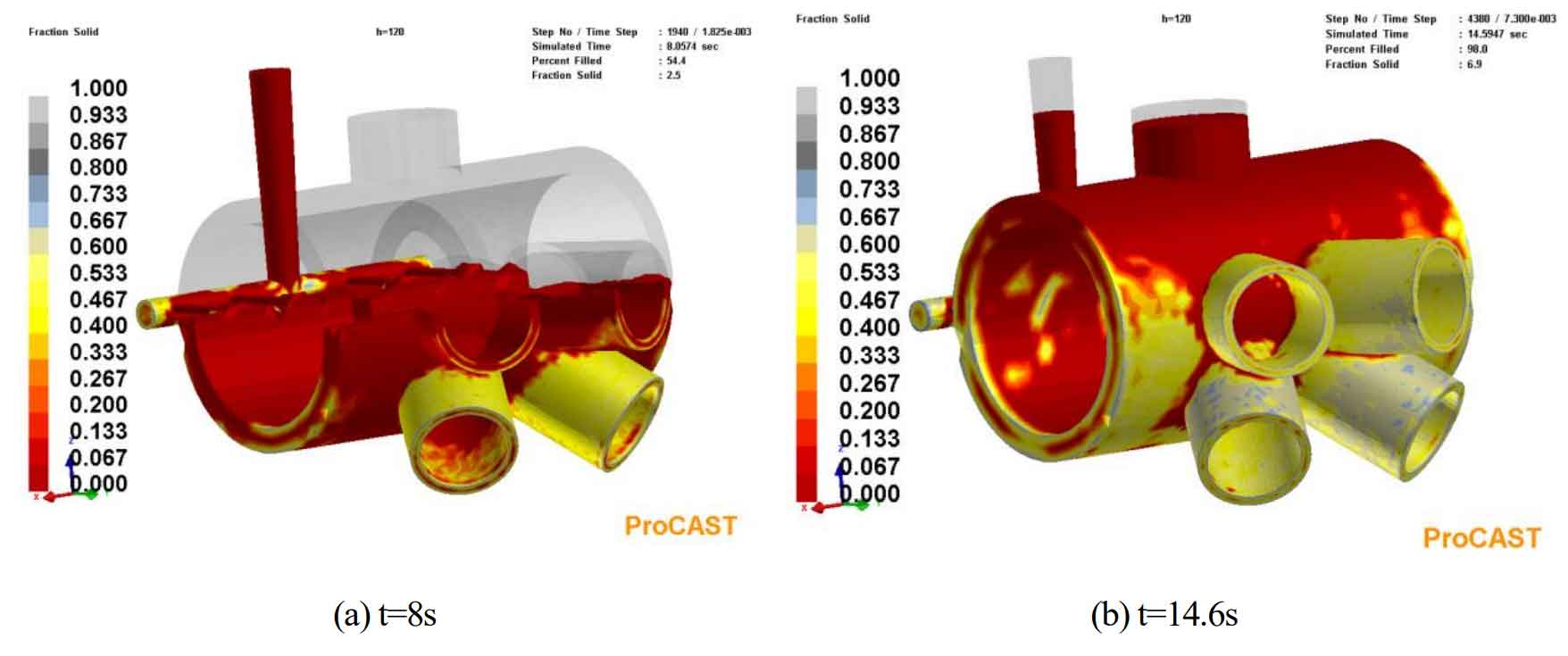

As shown in Figure 1, the mold filling is mainly steady laminar flow. The metal liquid rises slowly and fills the cast steel joint cavity smoothly. There are no defects such as insufficient pouring, which is conducive to obtaining dense castings. The total mold filling time is 16S. During the casting process, the metal liquid is injected from the gate under the action of gravity, flows through the sprue, transverse sprue and inner sprue, and enters the cast steel joint cavity. The casting speed is stable, indicating that the position and casting speed of the inner sprue can meet the requirements of stable mold filling.

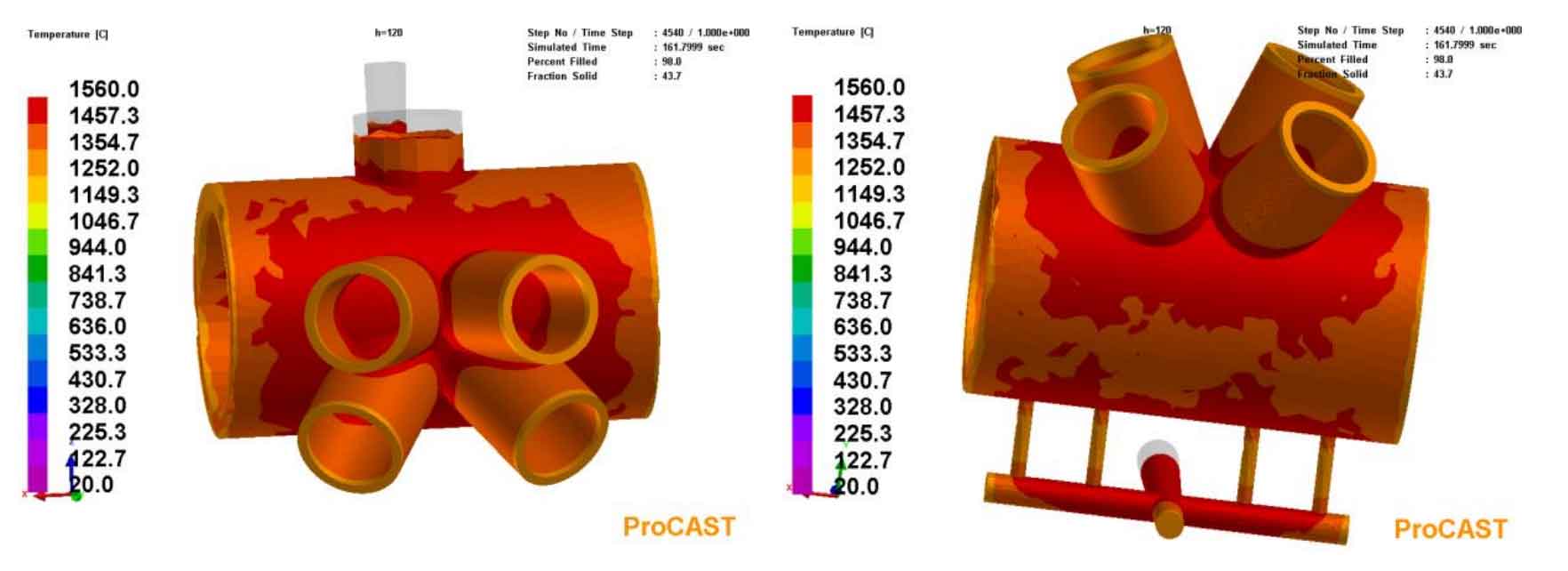

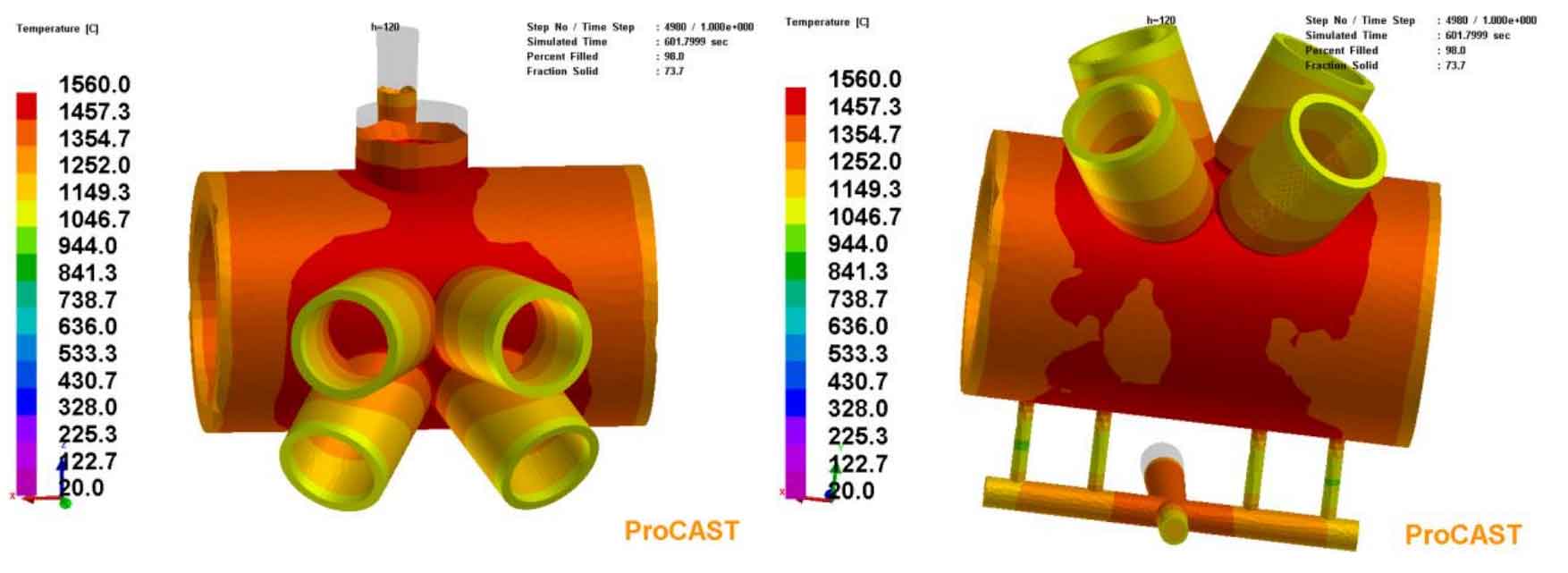

As shown in Fig. 2, Fig. 3 and Fig. 4, the changes of temperature field during solidification of cast steel joints are shown.

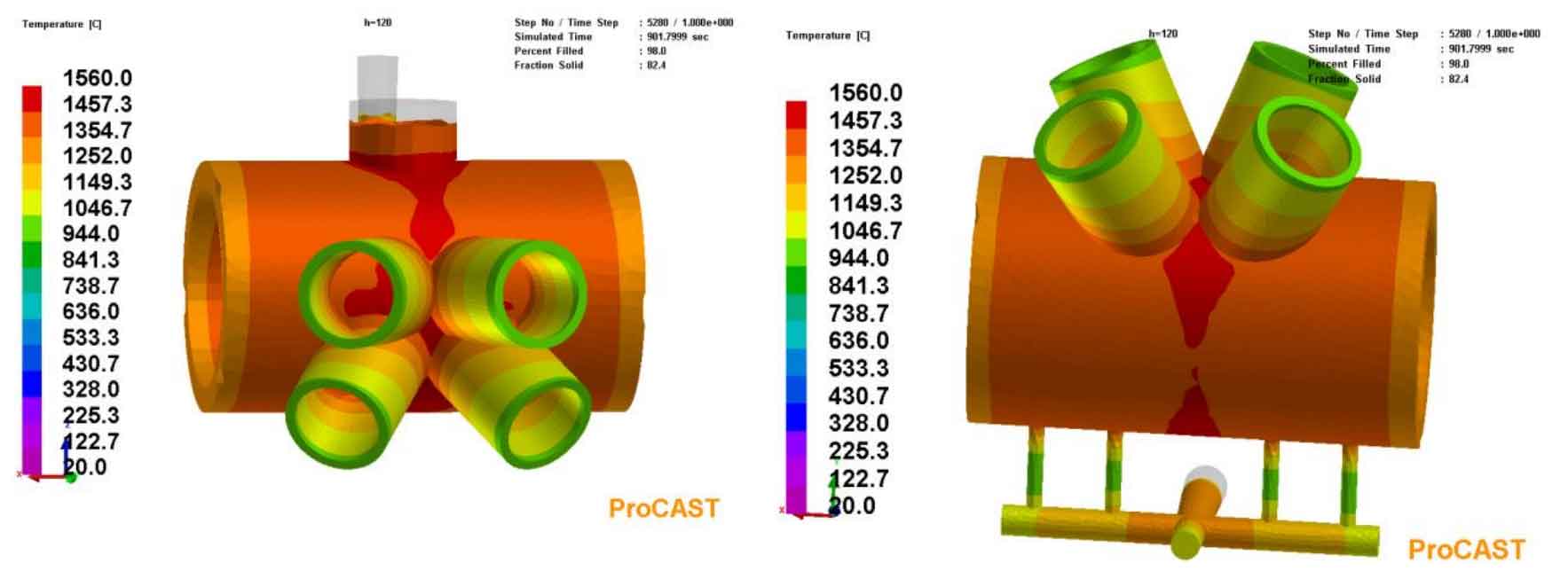

Figure 5 shows the distribution of solidification field of cast steel joints. Solidification begins at the branch pipe orifice and both ends of the main pipe. When the solidification proceeds to 43S, the solid volume reaches 32%. At this time, the intersection line is obviously still in the liquid area, which is about to form a closed liquid area; At 323s, the solid volume reached 61.3%. At this time, most of the cast steel joints had entered the solid state, but there was still some liquid at the root of the branch pipe and the riser; When the solidification reaches 6883s, the solid volume reaches 100%, and all the cast steel joints are solidified. It can be seen intuitively in the solidification process that the last solidified part is indeed the part near the intersection line, the part at the bottom of the casting and the riser. This is also very consistent with the actual experience of the factory and the description of technicians.

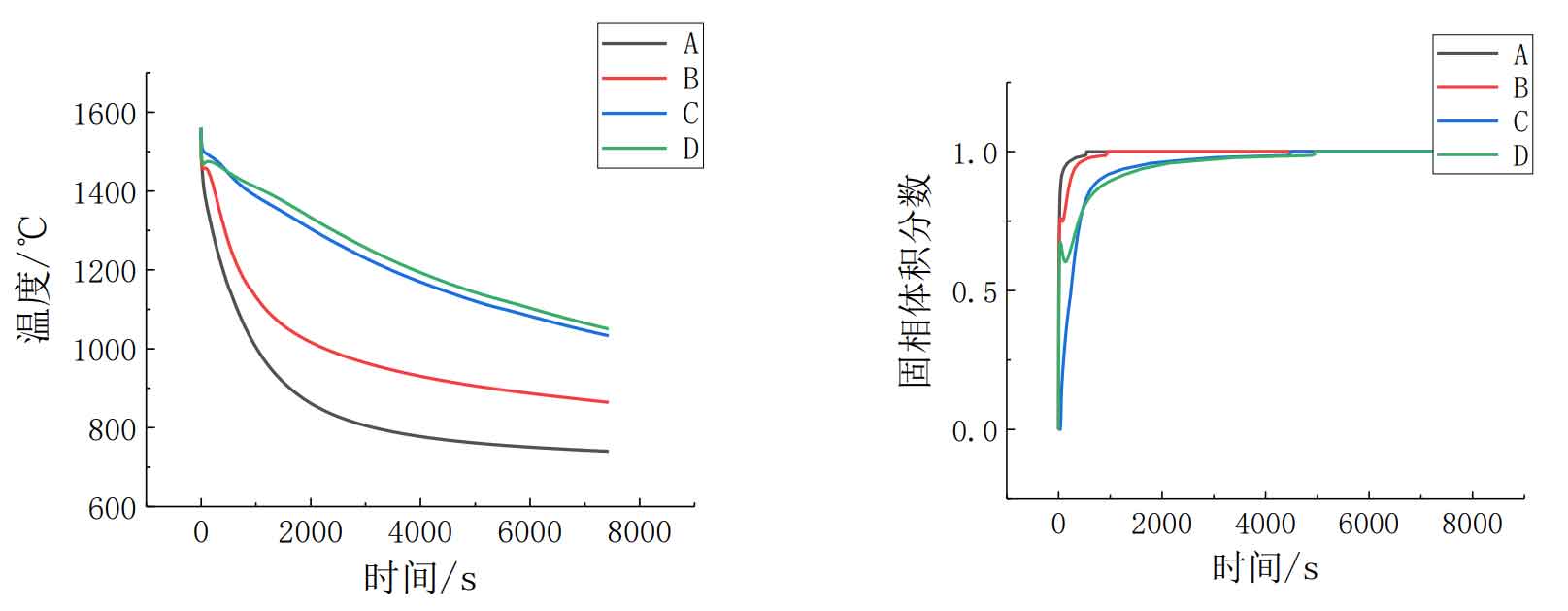

The initial solidification rate of cast steel joints is very fast, and the solidification rate becomes slower and slower with time, and finally completely solidified. The first 600s is the fastest stage of solidification, with the solidification volume accounting for 74.4%. The solid volume fraction reaches 90% at 1333s, and complete solidification takes 6883s. The last 10% solidification takes 5550s, accounting for 80.6% of the total solidification process.

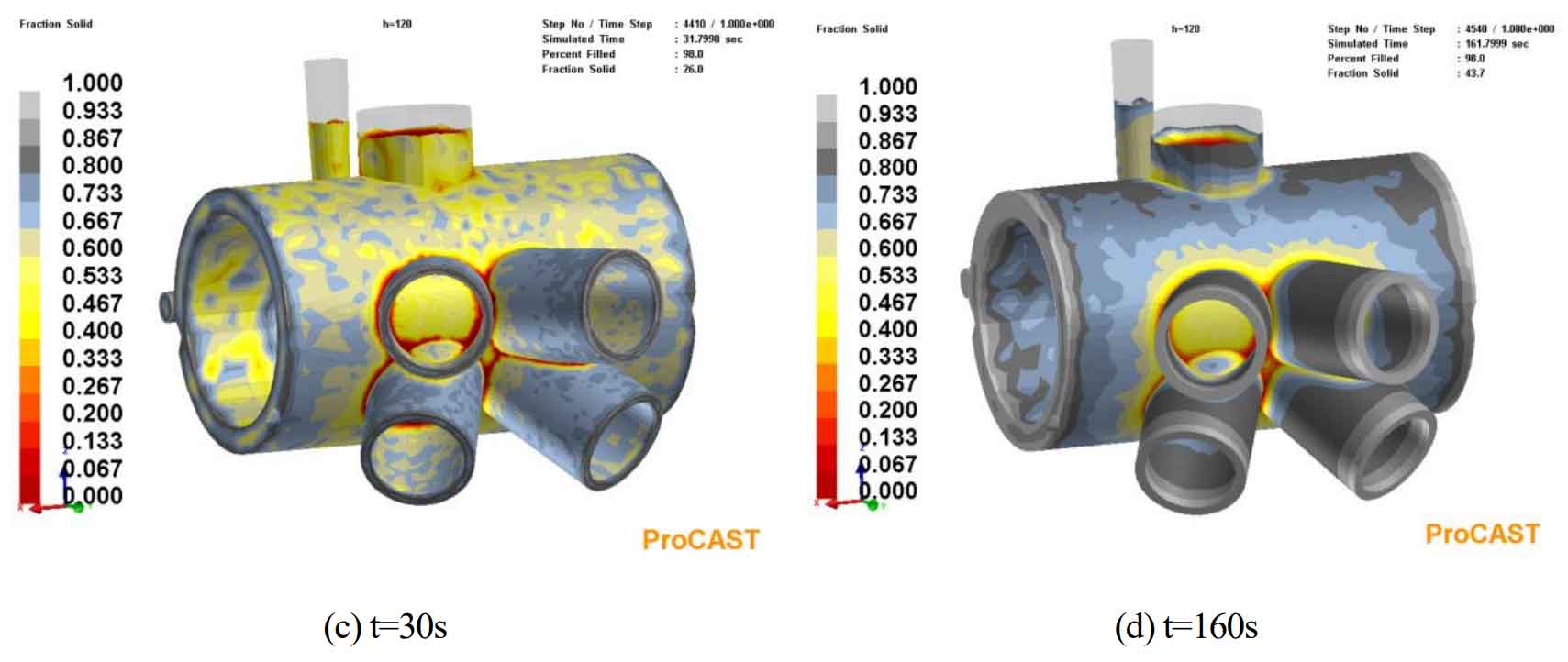

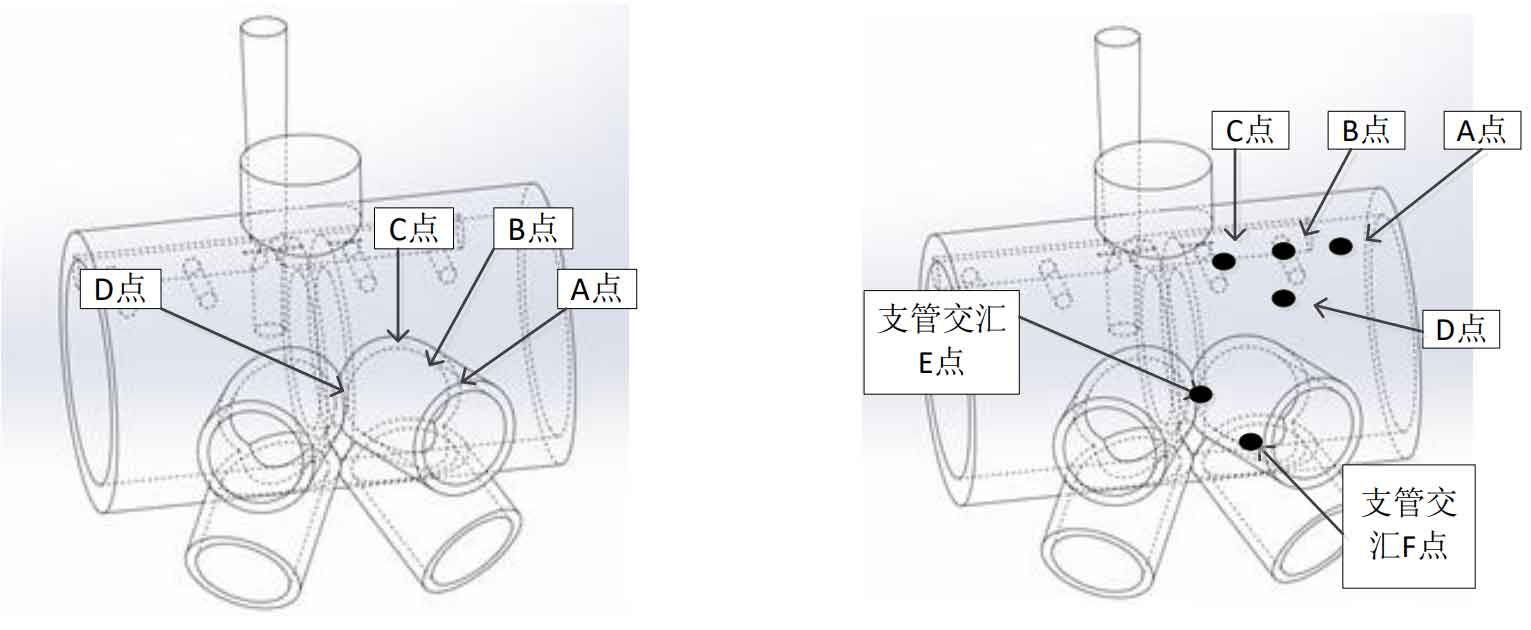

In order to further study the variation law of temperature and solid rate volume fraction near the branch pipe during solidification, select three points a, B and C along the axial direction of one branch pipe, corresponding to the nozzle, middle of the pipe and root of the pipe respectively, plus a point d at the intersection of the root of the branch pipe (Fig. 6). Obtain the temperature of these four points and the relationship curve between solid rate volume fraction and time through the post-processing module, as shown in Fig. 8 and Fig. 9.

It can be seen from Fig. 8 and Fig. 9 that the temperature drop rate in the area at the root of the branch pipe is very slow, and the solidification rate is also slow. A variety of defects may occur in this area. With the decrease of temperature, the strength and stiffness of the parts cooled earlier gradually increase. As the temperature decreases, the parts near the root of the branch pipe with slow cooling begin to produce large deformation and shrinkage. At this time, the parts around the earlier cooling have large strength and stiffness, and the deformation and shrinkage near the intersection line is subject to large resistance, so it is possible to form large stress and crack [48]. The crack of cast steel joint was detected at the root of branch pipe through magnetic particle flaw detection, which is also consistent with the reality.