The counterweight can adjust the service quality of the tractor and the mass distribution of the front and rear wheels, increase the adhesion of the tractor, ensure operation safety and improve traction efficiency. The rear wheel counterweight of a tractor was broken when assembling bolts, and the counterweight material was HT150 gray cast iron. In this paper, the causes of counterweight fracture are examined and analyzed by means of macro analysis, chemical composition analysis, metallographic examination, energy spectrum analysis and mechanical property analysis, and the corresponding solutions are put forward to avoid similar accidents.

1 Physical and chemical tests and results

1.1 Chemical composition analysis

Analyze the chemical composition of the counterweight, test results and recommended content. The content of phosphorus and manganese in the fractured counterweight material is high, and the content of other elements is within the recommended range.

1.2 Macro analysis and metallographic examination of fracture surface

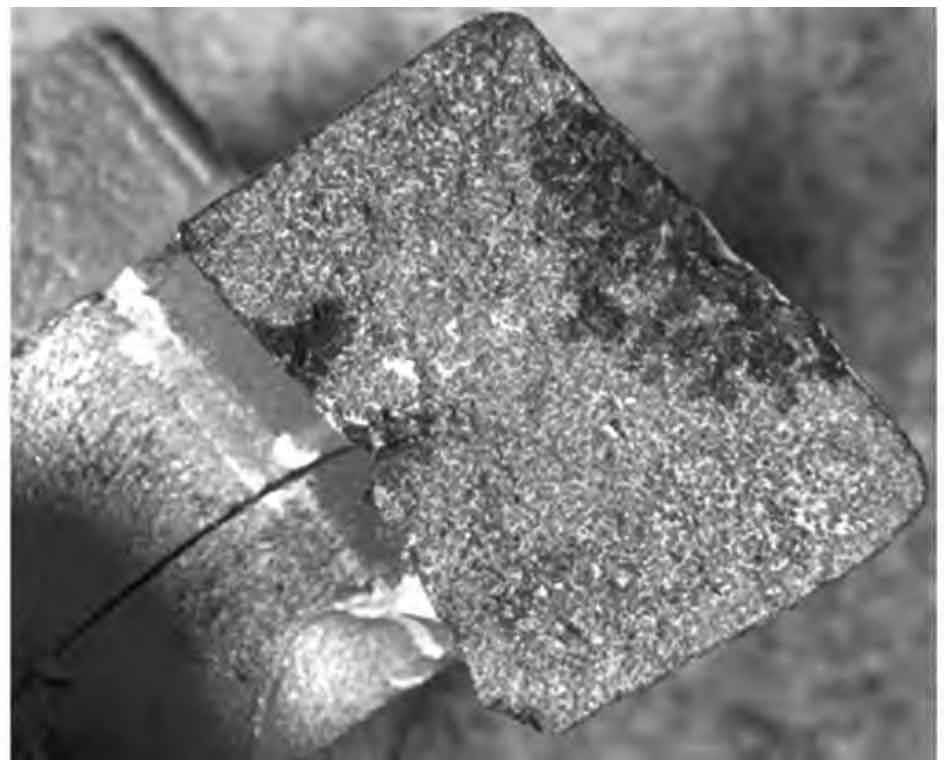

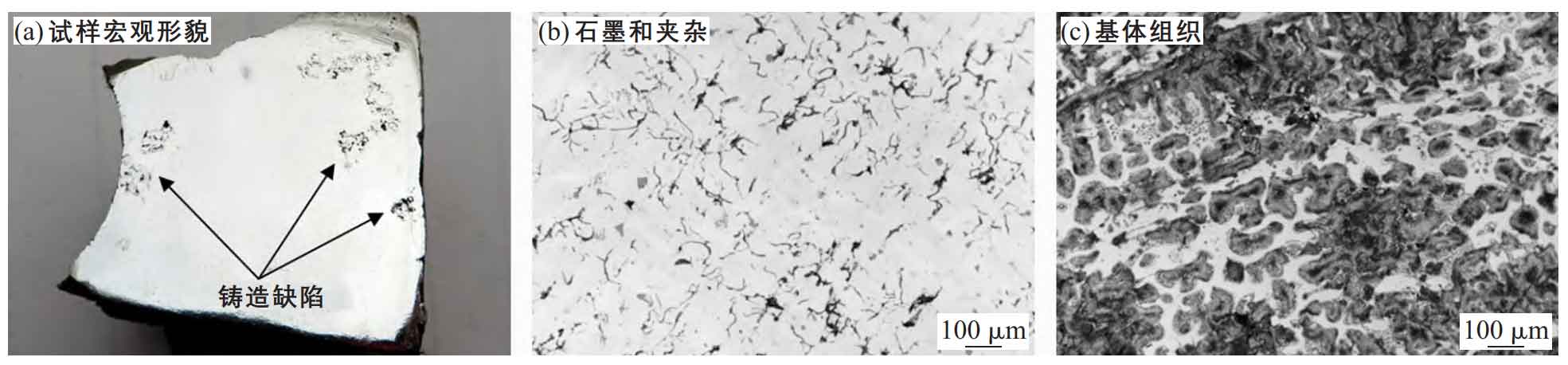

The rear wheel counterweight is disconnected as a whole along the bolt hole (Fig. 1). There are obvious casting defects such as porosity and shrinkage on the fracture (Fig. 2). The fracture surface is rough and uneven without obvious plastic deformation, which is a brittle fracture. Take samples near the fracture of the counterweight to make metallographic samples. Figure 3 (a) shows the macro morphology of the metallographic sample after grinding. It can be seen that there are casting defects on the metallographic grinding surface. Through microscopic observation, it is found that the graphite morphology of the sample is type A, and there are a large number of square and triangular inclusions, as shown in Fig. 3 (b). The matrix structure of the counterweight is pearlite + a large amount of phosphorus eutectic and carbide, as shown in Fig. 3 (c).

1.3 Energy spectrum analysis

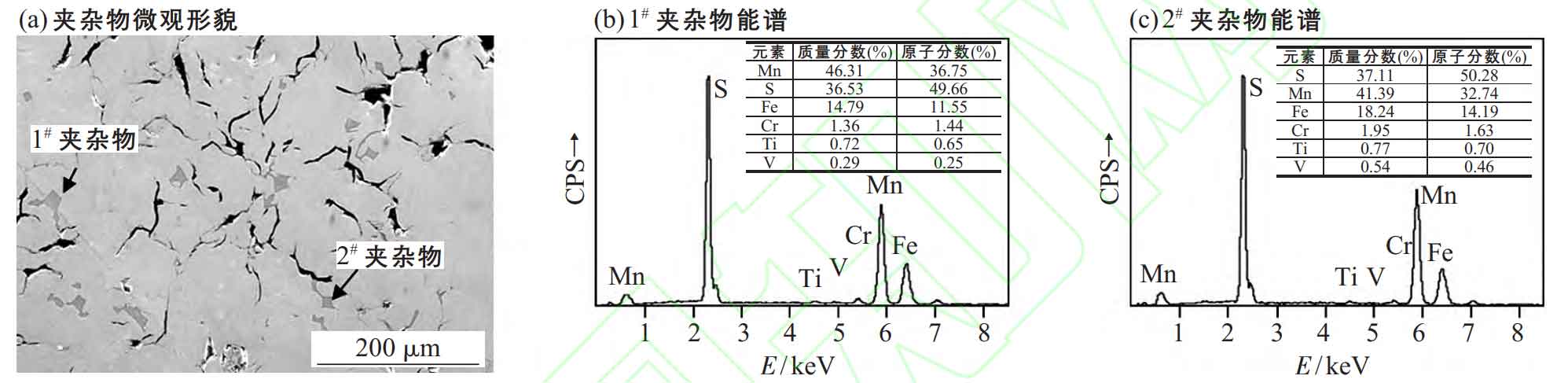

Through the microscopic observation of the metallographic sample of the counterweight with a scanning electron microscope, it is found that there are gray inclusions, as shown in Fig. 4 (a). Through the energy spectrum detection and analysis of gray inclusions, it is found that the contents of S and Mn in inclusions are high, so it is judged that the inclusions are manganese sulfide. The energy spectrum detection results are shown in Fig. 4 (b) and (c).

1.4 hardness test and tensile property test

The base hardness of the counterweight is 202 and 200hb, and the hardness meets the range of 125 ~ 205hb required by GB / T 9439-2010. Samples were taken on the counterweight for tensile strength test, and the results were 212 and 220 MPa, which met the requirements of gray iron castings (GB / T 9439-2010).

2 Analysis and discussion

(1) The influence of casting defects on the performance of counterweight. The plasticity of HT150 gray cast iron is very low, and there are many casting defects such as loose shrinkage cavities on the fracture surface of the counterweight. These defects will destroy the compactness and continuity of the counterweight material, reduce its bearing capacity, and directly affect its quality and service life.

(2) Effect of microstructure on counterweight performance. The microstructure of the counterweight is pearlite + flake graphite + a large number of phosphorus eutectic and carbide. Phosphorus eutectic and carbide are hard and brittle, and the interface adhesion between them and the matrix is poor, which will split the matrix and destroy its continuity, weaken the strength of grain boundary and increase the brittleness of gray cast iron. The phosphorus eutectic and carbide in the counterweight material are distributed in a continuous network, which seriously increases the brittleness of the material and causes brittle fracture during assembly.

(3) The influence of non-metallic inclusions on the performance of counterweight. The elastic modulus and expansion coefficient of non-metallic inclusions are different from those of the matrix, which is easy to produce stress concentration during stress, which affects the impact toughness and plasticity of the casting, and then affects its fatigue. There are many manganese sulfide inclusions in the metallographic structure of the counterweight. The existence of these inclusions will destroy the uniformity and continuity of the counterweight matrix, cause local stress concentration, easy to produce microcracks, and cause early damage to the material to a certain extent.

Based on the fracture characteristics, chemical composition analysis, microstructure and hardness test results of the counterweight, it is concluded that the main reason for the fracture of the counterweight is that the casting defects and a large number of phosphorus eutectic and carbide increase the brittleness of the parts, coupled with the local stress concentration caused by more non-metallic inclusions, which finally leads to the brittle fracture during the assembly of the counterweight.