Abstract

This paper introduces the common casting defects in producing frame castings using furan resin sand molding. The causes of these defects are analyzed, and improvement measures are proposed. These measures have significantly reduced the reject rate of frame castings in actual production.

1. Introduction

The base is an important part of the 430 vertical milling machine of Ningxia Xiaojuren Machine Tool Co., Ltd. It is made of HT300 material and weighs 1200 kg. The surface quality and casting dimensions are strictly required, and there must not be any casting defects on the two rail surfaces during machining. Our company uses the furan resin sand molding process to produce this casting. However, the reject rate of this casting is high. Therefore, we have reduced the reject rate through process improvements to provide satisfactory castings for customers.

2. Production Process

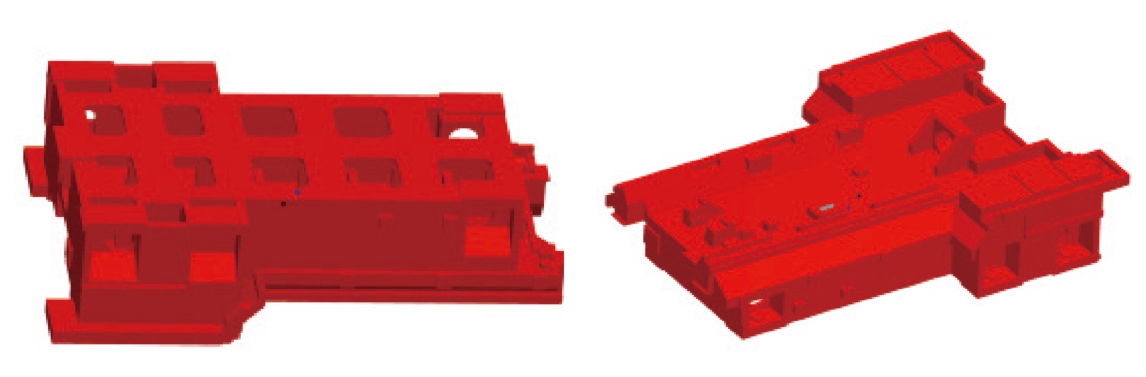

The casting has a complex shape with overall dimensions (length × width × height) of 1612 mm × 1165 mm × 425 mm, which poses high requirements for the molding process. The appearance of the casting.

This casting uses a wooden pattern, furan resin sand molding, and medium-frequency induction furnace for melting iron liquid.

3. Production Status Investigation

Statistics on the rejected products of this product in 2020 were conducted. A total of 130 pieces were produced, with 14 rejected pieces, resulting in a reject rate of 10.7%. The main types of rejected products are summarized in Table 1.

| Reject Type | Frequency (Pieces) | Percentage (%) |

|---|---|---|

| Deformation | 7 | 50 |

| Blowholes, Dirt Holes, Sand Holes | 2 | 14.3 |

| Shrinkage Cavities | 2 | 14.3 |

| Others | 3 | 21.4 |

| Total | 14 | 100 |

Table 1: Reject Statistics

As can be seen from Table 1, deformation defects account for 50% of the rejects. Therefore, deformation defects are the main quality issue of this casting.

4. Analysis of Deformation Defects

4.1 Influencing Factors Analysis

The influencing factors of deformation defects.

4.2 Main Cause Confirmation

After tracking and observing the actual production situation on site, the above influencing factors were confirmed. The main causes of deformation are summarized as follows:

| Cause | Confirmation Result |

|---|---|

| Early mold stripping | Not the cause |

| Poor stiffness of model baseplate | A cause |

| Low sand strength | Not the cause |

| Low casting material grade | A cause |

| Early opening of the casting box | Not the cause |

| Unreasonable gating system | A cause |

| Unevenness of the molding site | Not the cause |

5. Improvement Measures

5.1 Enhance the Stiffness of the Model Baseplate

To address the issue of insufficient stiffness of the baseplate, reinforcing ribs were added to the bottom of the model to ensure that the ground provides sufficient support points for the model, ensuring that the deformation of the baseplate during the molding process is less than 2.0 mm.

5.2 Improve the Casting Material Grade

To address the low casting material grade, 0.5% Cr was added during batching, and other chemical compositions were strictly controlled within the required range to ensure the casting material. After the improvement, the hardness of the castings was generally between 190 and 220 HBW, meeting the customer’s requirements.

5.3 Improve the Gating System

The gating system was improved by using a φ30 mm ceramic tube as the gate at the bottom of the two rails and opening three internal gates of 50/60 mm × 9 mm on one side of the casting to solve the problem of uneven gate distribution.

6. Improvement Effects

From January to June 2021, our company produced a total of 135 castings using the new process, with 4 rejects and a reject rate of 2.96%. The main types of rejected products after the improvement are summarized in Table 2.

| Reject Type | Frequency (Pieces) | Percentage (%) |

|---|---|---|

| Blowholes, Sand Holes | 2 | 50 |

| Shrinkage Cavities | 1 | 25 |

| Others | 1 | 25 |

| Total | 4 | 100 |

Table 2: Reject Statistics After Improvement

By comparing the reject rates before and after the process improvement, it can be found that the deformation problem has been completely solved.

7. Conclusion

In actual production, it is found that for frame castings, due to their complex shapes and uneven wall thicknesses, the strength of the casting mold itself should be considered when making the casting mold to ensure that it does not affect the quality of the casting during production. When designing the gating system, the stress generated during the cooling process should be considered to prevent stress concentration. The chemical composition of gray iron castings should be strictly controlled to ensure they meet the required properties.