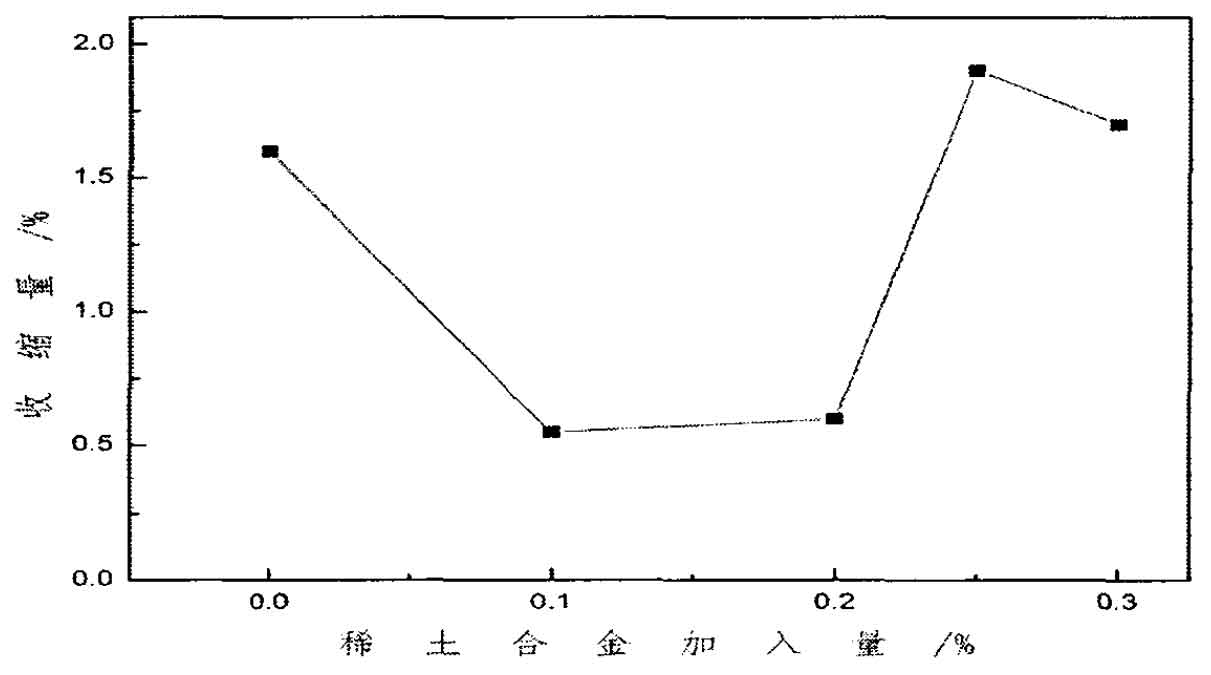

It can be seen from the measurement results of free linear shrinkage and its corresponding relationship curve in the table that the shrinkage rate of low-carbon equivalent gray cast iron is large. With the increase of rare earth alloy, the shrinkage of low-carbon equivalent gray cast iron sample decreases first and then increases, and the shrinkage rate is the smallest when the addition of rare earth alloy is 0.1%; When the amount of rare earth alloy reaches 0.2%, the shrinkage of low carbon equivalent gray cast iron turns again, and the shrinkage increases gradually, reaching the maximum when the amount of alloy is 0.25%.

| Alloy content% | 0 | 0.1 | 0.2 | 0.25 | 0.3 |

| L0(mm) | 120.00 | 119.72 | 117.06 | 119.90 | 119.70 |

| L(mm) | 118.08 | 119.06 | 116.36 | 117.66 | 117.68 |

| ε(%) | 1.6 | 0.55 | 0.60 | 1.9 | 1.7 |

When adding a small amount of inoculant to low carbon equivalent gray cast iron, rare earth alloy can promote graphitization, precipitate a certain amount of graphite and reduce solidification shrinkage. It is easy to obtain excellent gray cast iron, and the graphitization degree reaches the highest value when reaching the critical value. With the continuous increase of the amount of rare earth alloy, the rare earth alloy plays an anti graphitization role, and the amount of graphite increases

The graphitization expansion of gray cast iron during solidification decreases, which is why the shrinkage of low carbon equivalent gray cast iron sample increases again.