Analysis and Process Improvement of Shrinkage Defects in Main Reducer Shell Casting

In automotive shell casting applications, the main reducer housing is a critical drivetrain component introduced to China’s heavy-duty truck industry from German Mercedes-Benz technology in the late 20th century. This shell casting maintains stable market demand across truck models with minimal dimensional variations. Recent quality upgrades mandate zero tolerance for shrinkage defects, prompting our comprehensive study of existing shell casting processes to identify improvement strategies.

Current Shell Casting Production Overview

The shell casting process employs a KW horizontal molding line with air-flow pre-compaction and high-pressure multi-piston squeezing at 1.25 MPa maximum specific pressure. Mold dimensions are 1,100 × 900 × 350/250 mm, achieving 90 molds/hour productivity. Key parameters for the QT450-10 shell casting include:

| Parameter | Value |

|---|---|

| Single Weight | 37.5 kg |

| Dimensions | 548 × 360 × 180 mm |

| Wall Thickness | 12 mm (nominal) |

| Pouring Temperature | 1,380–1,420°C |

Chemical composition of molten iron:

| Element | Content (%) |

|---|---|

| C | 3.65–3.95 |

| Si | 2.55–2.85 |

| Mn | 0.1–0.4 |

| P | ≤0.06 |

| S | ≤0.02 |

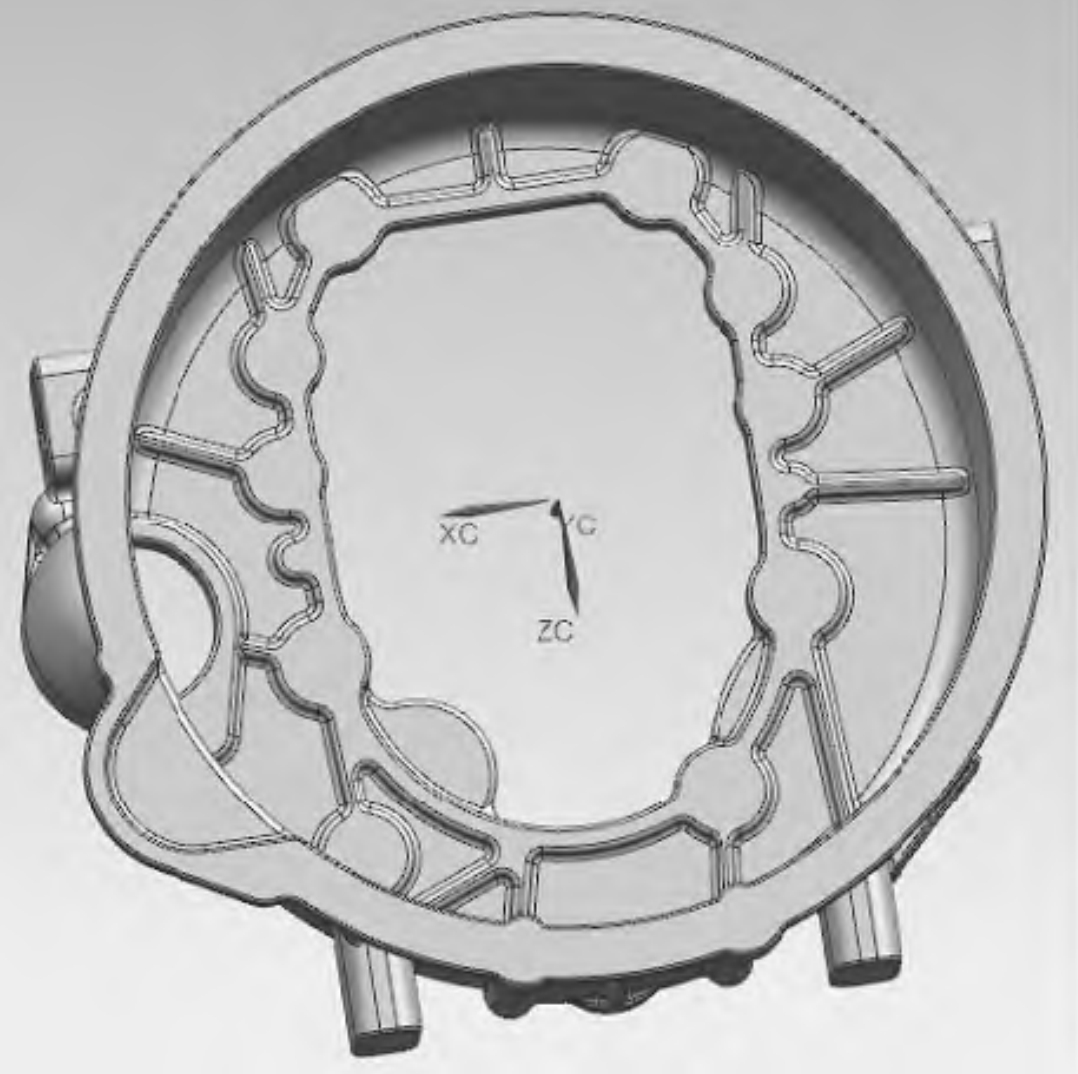

The shell casting process uses three cavities per mold with bottom-gating systems. Runners are positioned near corners to maximize mold utilization, with two gates per casting. Risers supplement thick sections while vent pins and cooling ribs address gas escape and local solidification control. Thermal core technology prepares sand cores for complex internal geometries.

Shrinkage Defect Analysis in Shell Castings

Metallurgical analysis revealed shrinkage defects predominantly at bearing seat interfaces and shift fork bosses – regions combining vertical and horizontal planes. These correspond to structural hot spots where heat accumulation prolongs solidification. Seven critical hot spots were identified:

$$ t_s = \frac{V}{A} \cdot C $$

Where \( t_s \) = solidification time, \( V \) = volume, \( A \) = surface area, and \( C \) = mold constant. Extended solidification in thick sections exceeds riser feeding capacity, causing shrinkage porosity.

| Hot Spot | Location | Defect Severity |

|---|---|---|

| 1 | Shift fork boss | High |

| 2 | Bearing seat interface | High |

| 3 | Flange junction | Medium |

| 4–7 | Lower housing | None |

Simulation demonstrated premature solidification between risers and Hot Spot 1, creating isolated liquid zones. Riser inadequacy was quantified through modulus comparisons:

$$ M_{riser} = 1.2 \times M_{casting} $$

Original risers satisfied modulus (\( M \)) requirements but failed volume feeding criteria:

$$ V_{feed} \geq \frac{V_c \cdot \alpha}{ε – \alpha} $$

Where \( V_{feed} \) = required feed volume, \( V_c \) = casting volume, \( α \) = shrinkage ratio (6.5% for QT450-10), and \( ε \) = riser efficiency.

Shell Casting Process Optimization

Modifications addressed both structural and process-induced hot spots:

- : Implemented semi-open/semi-choked system with area ratios:

$$ ΣS_{sprue} : ΣS_{runner} : ΣS_{gate} = 1 : 1.15 : 1.3 $$

Flow restrictors reduced metal velocity at runner bends - Enhanced feeding: Upgraded risers to Ø80 mm with volume-based verification:

$$ V_{riser} = 1.8 \times \left( \frac{V_c \cdot \alpha}{ε} \right) $$ - Exothermic risers: Added Ø60×90 mm exothermic sleeves to Hot Spot 1

$$ t_{exo} = 1.25 \times t_{std} $$

(25% extended feeding duration)

Assembly innovations ensured process reliability:

| Component | Improvement | Function |

|---|---|---|

| Riser assembly | Adhesive-bonded exothermic sleeve/breaker core | Prevent core drop |

| Riser tooling | Interference-fit grooves | Secure positioning |

Optimized thermal management achieved through:

$$ \nabla T_{optimized} = 0.75 \times \nabla T_{original} $$

(25% reduced thermal gradients)

Validation Results in Shell Casting Production

Post-optimization analysis confirmed complete elimination of shrinkage in all hot spots. Production validation across 6,031 shell castings showed sustained quality improvement:

| Month | Production | Rejects | Reject Rate (%) |

|---|---|---|---|

| September | 65 | 7 | 10.77 |

| October | 1,250 | 15 | 1.20 |

| November | 2,180 | 18 | 0.83 |

| December | 2,536 | 19 | 0.75 |

| Total | 6,031 | 59 | 0.98 |

Notably, zero rejects stemmed from shrinkage defects after optimization. Final quality metrics exceeded client specifications while maintaining 90 molds/hour productivity.

Conclusion

This shell casting improvement demonstrates three critical principles for shrinkage mitigation: First, strategic riser placement at structural hot spots prevents isolated liquid zones. Second, exothermic riser technology enhances feeding efficiency where conventional methods fail, particularly for elevated sections like shift fork bosses. Third, integrated verification through simulation and statistical process control ensures robust solutions. These techniques provide transferable methodologies for complex shell castings across automotive applications, proving particularly effective for housing-type components with non-uniform wall thickness and internal features requiring precise soundness standards.