Cast iron is the most widely used casting metal material in modern industry. The applications of cast iron in various fields of national economy are numerous. With the development of industry and technology, the mechanical properties, processability and economy of cast iron raw materials are continuously improved. As one of the common raw materials of cast iron, gray cast iron is one of the typical cast iron because of its many excellent characteristics, such as good machinability, wear resistance, low melting point, low price and so on. The lubricating oil in the graphite film is easy to keep loose, and the lubricating oil in the graphite film has better wettability. In addition, when gray cast iron is subjected to vibration, the existence of graphite can effectively prevent the transmission of vibration and play the role of buffer and shock absorption. It is usually used in the bed of precision machine tools.

With the continuous improvement of modern machining and manufacturing technology, the requirements for machining efficiency and machining accuracy of NC machine tools and machining centers are becoming more and more strict, which makes NC machine tools and machining centers develop towards high precision and efficiency. It forces the improvement of feed speed and positioning accuracy in the machining process, which also makes great changes in the guiding mechanism of traditional machine tools. Based on such a requirement, the rolling guide came into being and developed rapidly in the 1970s. The rolling guide rail is a form of linear guide rail. It places rolling elements such as balls, rollers and needles between the guide rail surfaces, so that the wear form between the guide rail and the worktable changes from sliding friction to rolling friction, which obviously reduces the friction coefficient (0.003 ~ 0.005), so as to reduce the heat generated by wear. For the feature of less heating, the high-speed movement of the machine tool can be realized and the working efficiency of the machine tool can be improved by 20 ~ 30%. At the same time, it has flexible movement, good low-speed movement stability, and is not easy to crawl. It can be pre tightened, with high stiffness, long service life and high precision. The positioning accuracy can reach 0.1 ~ 0.2 μ m. Easy lubrication and other characteristics. At present, it has been widely used in CNC machine tools, precision electronic machinery, measuring instruments and industrial robots.

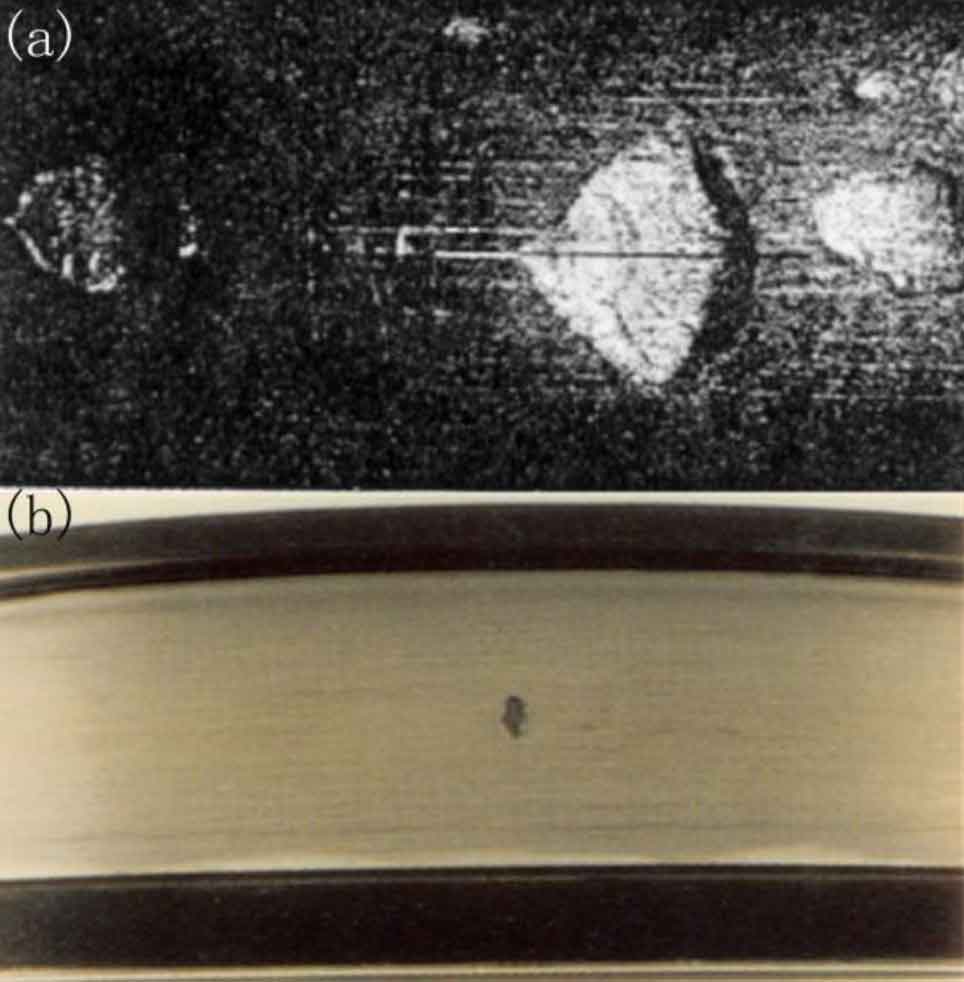

However, in the process of use, although the working load is far less than the allowable stress of the material, under the action of periodic alternating stress (Hertz contact), a large number of fatigue defects will still appear on the material surface (Figure), which will seriously affect the quality of processed products and even hide huge potential safety hazards. The guide rail with fatigue defects has to be scrapped, resulting in a great waste of materials. In order to reduce waste, in modern industry, hard steel sheets are usually embedded in gray cast iron bed to meet the requirements of this kind of guide rail, which is called steel inlaid guide rail. Because of its good wear resistance, high hardness, strong rigidity and not easy to deform, steel inlaid guide rail has been used more and more. It not only greatly improves the accuracy of machine tool, but also enhances the ability of machine tool to bear large load. However, the steel inlaid guide rail also has some disadvantages, such as small section, long length, easy quenching deformation, asymmetric shape, difficult processing, high processing requirements and high cost. The most important thing is that the probability of fatigue defects increases to a great extent at the connection between steel sheet and steel sheet and steel sheet matrix.