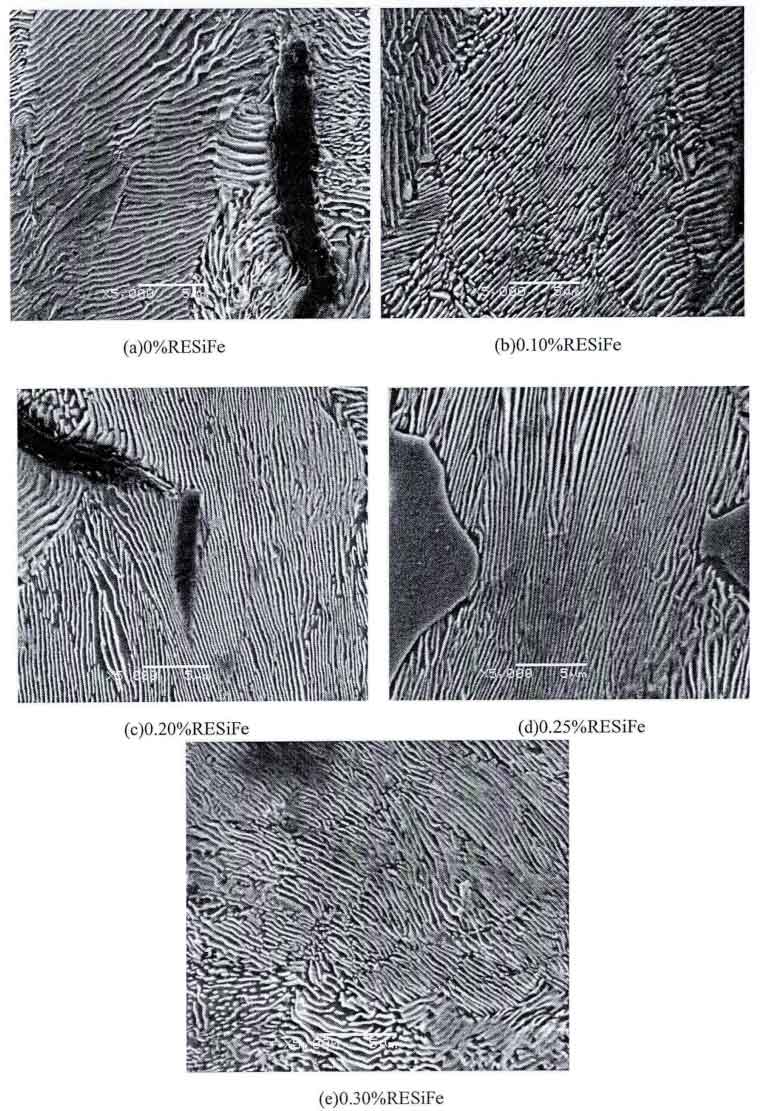

Generally speaking, the eutectoid transformation starts from the formation of cementite sheet at the austenite grain boundary. The formation and growth of cementite sheet will promote the formation of relative carbon poor areas on both sides. The emergence of carbon poor areas provides power for the formation and growth of ferrite sheet, and the formation and growth of ferrite sheet in turn will produce relatively carbon rich areas around ferrite, The formation of carbon rich zone once again provides power for the formation and growth of cementite sheet. In this way, the ferrite sheet and cementite sheet continuously promote each other and grow layer by layer, and finally grow into lamellar pearlite. The morphology of pearlite lamellar structure is shown in the figure.

Rare earth has obvious effect of rare earth pearlite flake spacing. With the increase of rare earth addition, the flake spacing of pearlite will become smaller and smaller; When the amount of rare earth and pearlite reaches 1.0%, the relative distance between pearlite and pearlite is small. For lamellar pearlite, the strength and hardness of gray cast iron are closely related to it. Generally speaking, the reduction of pearlite sheet spacing will improve the strength and hardness of gray cast iron. The layer spacing of flake pearlite is mainly determined by the eutectoid decomposition temperature of austenite, that is, the degree of eutectoid transformation undercooling. The greater the degree of eutectoid transformation undercooling, the smaller the flake spacing of pearlite. It can be seen from the pearlite structure of low carbon equivalent gray cast iron before and after the addition of rare earth: the addition of rare earth alloy can significantly increase the undercooling of molten iron, reduce the carbon concentration required to form cementite, and increase the growth rate of alloy cementite in cementite, so as to reduce the thickness of ferrite sheet, accelerate the eutectoid transformation rate, and finally reduce the sheet spacing of pearlite sheet, Strengthen the matrix and improve the mechanical properties of gray cast iron. Therefore, even if the amount of pearlite in gray cast iron is small, the tensile strength of gray cast iron still changes little, mainly because the addition of rare earth reduces the pearlite sheet spacing, which is also an important index affecting the strength of gray cast iron.