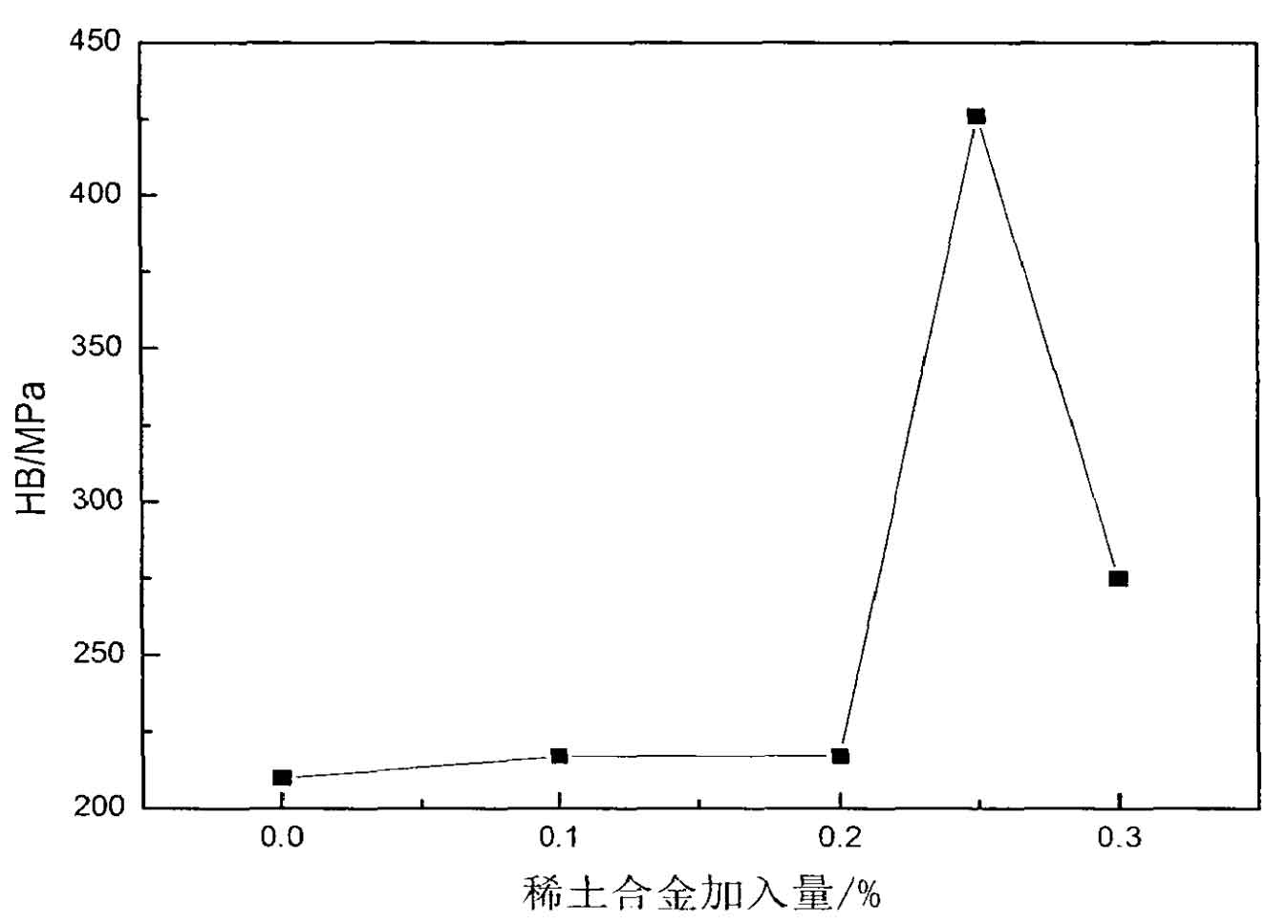

The hardness of low carbon equivalent gray cast iron treated with rare earth is also compared with HT250 inoculated with molten iron in the same furnace plus Si Fe. The relationship is shown in the table.

| Furnace No. | 1 | 2 | 3 | 4 | 5 |

| Si-Fe alloy addition /% | 0.5 | ||||

| Addition amount of rare earth alloy /% | 0 | 0.1 | 0.2 | 0.25 | 0.3 |

| HB/MPa | 205 | 217 | 217 | 426 | 275 |

It can be seen from the table and its corresponding figure that rare earth inoculation can effectively improve the hardness of low carbon equivalent gray cast iron compared with ferrosilicon inoculation.

When the amount of rare earth alloy is controlled within a certain range (the amount of alloy is less than 0.2%), the rare earth alloy has little effect on the hardness of low carbon equivalent gray cast iron. Only when the amount of rare earth alloy reaches 0.2%, the hardness of gray cast iron increases sharply with the increase of the amount of rare earth ferrosilicon. When the amount of rare earth alloy reaches 0.25%, the hardness of gray cast iron decreases again.

When the amount of rare earth alloy is 0.1%, the hardness of the sample is significantly higher than that of the sample inoculated with ferrosilicon, which also shows that the inoculation effect of rare earth is better than that of ferrosilicon. The addition of rare earth alloy is conducive to the formation of graphite. The amount of graphite increases, and the graphite morphology gradually changes from coarse block flake graphite to fine flake graphite. The increased toughness and plasticity of gray cast iron will inevitably reduce the hardness of gray cast iron, but the large amount of pearlite and the decrease of pearlite flake spacing reduce this effect to the lowest; When the amount of rare earth is more than 0.2%, the white cast iron tends to increase, a large amount of graphite accumulates, and some areas tend to change to white cast iron. Therefore, the hardness increases sharply. If rare earth is added continuously, the spheroidization of the sample increases obviously, shrinkage defects appear in the center of the sample, and the hardness decreases again.