1. Introduction

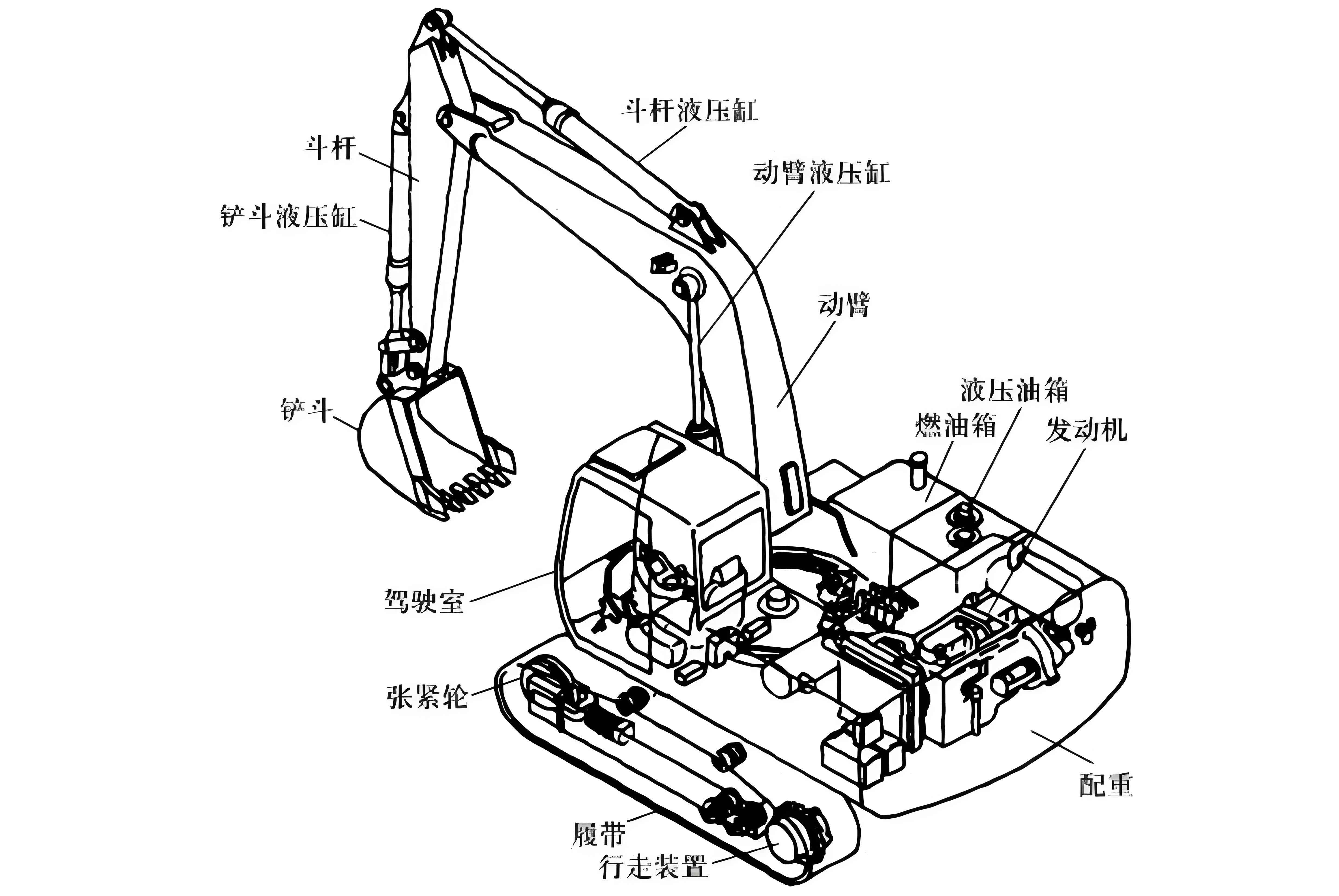

Bucket teeth are crucial components of excavators as they directly interact with soil and rocks. These components are subjected to intense impacts, bending, and sliding forces during operation, leading to wear and deformation. Therefore, the steel used for bucket teeth must possess high strength, high toughness, and wear resistance. Forging generally imparts better comprehensive mechanical properties compared to casting. After forging, workpieces usually undergo subsequent heat treatment processes such as quenching. Currently, conventional quenching after forging or forging remnant – heat quenching are commonly used methods. In this study, an improved “semi – forging remnant – heat quenching” process for producing bucket teeth of mining excavators is proposed. This process can eliminate the adverse effects of banded structures and improve strength and toughness compared to the forging remnant – heat quenching process. It can also save energy and working hours compared to the forging conventional quenching process.

2. Experimental Methods

2.1 Materials

The experimental steel used was a commercial 40Cr steel, and its chemical composition is shown in Table 1.

| Element | Si | Mn | Cr | S | P | Fe |

|---|---|---|---|---|---|---|

| Content | 0.28 | 0.65 | 0.98 | <0.04 | <0.04 | Remainder |

2.2 Experimental Scheme

For the “semi – forging remnant – heat quenching” experiment, after high – temperature forging, the part was first rapidly cooled to a critical temperature below the pearlite transformation temperature and held at this temperature for a sufficient time to form an equiaxed structure. Subsequently, the workpiece was reheated to the austenite transformation zone temperature and finally quenched and tempered. The key to this technology is to determine the critical temperature at which the workpiece can complete the pearlite transformation after forging. Test specimens for measuring the critical temperature were cut from a Φ25 mm × 1000 mm forged bar, with a size of Φ25 mm × 15 mm. The heat treatment process flow for measuring the critical temperature is shown in Figure 1. The specimens were reheated to 860°C in an electric resistance furnace and held for 60 min, then rapidly cooled to a temperature T (T was set to 780, 720, 700, 670, 650, 630, and 610°C respectively) using a fan for blowing, held at this temperature for 30 min, and then water – cooled to room temperature. After mechanical polishing and corrosion with 4% nitric acid alcohol, the heat treatment microstructures of each specimen were observed using an optical microscope and a scanning electron microscope (SEM). The Rockwell hardness of each specimen under a 150 N load was measured at room temperature.

3. Experimental Results and Discussion

3.1 Hardness Analysis

Figure 2 shows the hardness of the specimens after heat treatment at the T temperature shown in Figure 1. When the temperature was 670°C or higher, the specimen hardness was approximately 55 (HRC); when the temperature was 650°C or lower, the specimen hardness was around 15 (HRC). The temperature at which the hardness changed significantly was between 650 – 680°C.

3.2 Microstructure Analysis

Figure 3 shows the microstructures of the specimens corresponding to T = 680°C and 650°C in Figure 1. At T = 680°C, the structure was “proeutectoid ferrite + martensite”, where the blocky grains were proeutectoid ferrite and the darker ones were martensite. At T = 650°C, the structure was “proeutectoid ferrite + pearlite”, where the white grains were proeutectoid ferrite and the dark brown ones were pearlite. From these microstructures, it can be seen that the transformation from austenite to pearlite did not occur at 680°C and above but could be completed at 650°C and below. Therefore, the critical temperature in the semi – forging remnant – heat quenching process can be selected as 650°C.

3.3 Process Comparison

Based on the above results, the heat treatment process flowcharts for producing bucket teeth using the semi – forging remnant – heat quenching, forging remnant – heat quenching, and forging conventional quenching processes are shown in Figure 4 (a), (b), and (c) respectively. Table 2 shows the mechanical properties of the specimens prepared using the three different heat treatment process flows shown in Figure 4.

| Process | Hardness (HRC) | Impact Energy (J·cm) |

|---|---|---|

| Semi – forging remnant – heat quenching | 45 | 35 |

| Forging remnant – heat quenching | 44 | 5 |

| Forging conventional quenching | 45 | 34 |

It can be seen from Table 2 that the hardness of the specimens produced by the three different heat treatment processes was basically the same. The impact energy of the specimens produced by the “semi – forging remnant – heat quenching” process and the “forging conventional quenching” process was basically equal but much higher than that of the specimens produced by the “forging remnant – heat quenching” process.

3.4 Process Analysis

According to the relevant theory of thermal deformation, the three heat treatment processes have a soaking temperature of 1200°C, and the same forging deformation process is adopted between 1200 – 860°C. The purpose of pre – forging soaking is to ensure uniform austenitization of the steel. The final forging temperature is also an important process parameter. If the temperature is too high, the steel grains will grow, reducing the mechanical properties; if the temperature is too low, sufficient grain refinement cannot be obtained in the austenite single – phase region, which has an adverse impact on the final properties and increases the deformation resistance, making deformation difficult.

For the “semi – forging remnant – heat quenching” process flow, after forging deformation, the workpiece is cooled to 650°C and held for 30 min to complete the pearlite transformation and eliminate the deformation structure during forging. Then it is reheated to 860°C and held for 90 min for austenitization, quenched, and then tempered at 380°C for 180 min. The key point in this process is cooling to 650°C and holding for 30 min to cause a phase transformation in 40Cr steel to generate pearlite and eliminate the deformation structure during forging.

For the “forging remnant – heat quenching” process flow, considering that the subsequent quenching heat treatment temperature is often basically the same as the final forging temperature, rapid quenching after forging obtains a quenched martensite structure, and the deformation structure after forging is not eliminated before quenching and will be inherited after quenching. Therefore, the banded structure produced by forging cannot be eliminated in the final structure, resulting in a lower impact energy and not meeting the requirements for high impact toughness of bucket teeth products.

The “forging conventional quenching” process is a relatively common production process that can obtain good hardness and impact energy. However, after the forging is cooled to room temperature, it needs to be reheated from room temperature before quenching, which increases energy consumption and working hours compared to the first two production processes.

In conclusion, compared to the “forging remnant – heat quenching” process, the “semi – forging remnant – heat quenching” process can obtain better impact toughness; compared to the “forging conventional quenching” process, it can save energy and working hours, meeting the requirements of a low – carbon economy and improving production efficiency. The “semi – forging remnant – heat quenching” technology provides a low – cost, low – carbon new method for the development of high – performance bucket teeth.

4. Conclusions

4.1 Critical Temperature Determination

The key to the “semi – forging remnant – heat quenching” process is to determine the critical temperature for completing the pearlite transformation. For 40Cr steel, the critical temperature is 650°C. When 40Cr steel is forged and deformed, it is cooled to 650°C and held for 30 min to complete the pearlite transformation and eliminate the forging deformation structure. Through subsequent heat treatment, the forging deformation structure can be completely eliminated.

4.2 Process Advantages

The “semi – forging remnant – heat quenching” process has better impact toughness compared to the “forging remnant – heat quenching” process and can save energy and working hours compared to the “forging conventional quenching” process.

5. Future Research Directions

5.1 Optimization of Process Parameters

Although the semi – forging remnant – heat quenching process has shown certain advantages in this study, there is still room for optimization of process parameters. For example, the holding time at different temperatures can be further explored to achieve better microstructure and mechanical properties. The influence of cooling rates on the final product quality also needs to be studied in more detail. Different cooling media and cooling methods may lead to different microstructures and properties of bucket teeth.

5.2 Application to Other Steels

The current research focuses on 40Cr steel. Future research can explore the application of this semi – forging remnant – heat quenching process to other steels used for bucket teeth or similar wear – resistant components. Different steels have different chemical compositions and phase transformation characteristics, and it is necessary to study how to adapt this process to different steel materials to achieve better performance.

5.3 Long – term Performance Evaluation

In actual working conditions, bucket teeth are subjected to long – term wear and impact. Therefore, it is necessary to conduct long – term performance evaluation of bucket teeth produced by the semi – forging remnant – heat quenching process. This includes studying the wear resistance, fatigue life, and impact toughness changes of bucket teeth over a long period of time to ensure that they can meet the requirements of actual working conditions.

5.4 Numerical Simulation of the Process

With the development of computer technology, numerical simulation of heat treatment processes has become an important research method. Future research can use numerical simulation software to simulate the semi – forging remnant – heat quenching process, predict the microstructure and mechanical properties of bucket teeth, and provide a theoretical basis for process optimization. This can help to reduce experimental costs and shorten the research and development cycle.

6. Industrial Application and Significance

6.1 Industrial Application

The semi – forging remnant – heat quenching process has significant potential for industrial application in the production of bucket teeth. By using this process, manufacturers can produce bucket teeth with better mechanical properties, which can improve the working efficiency and service life of excavators. In addition, the energy – saving and time – saving advantages of this process can also reduce production costs and increase production efficiency, making it more competitive in the market.

6.2 Significance

This research is of great significance for the development of the bucket teeth manufacturing industry. It provides a new method for improving the quality of bucket teeth and reducing production costs. At the same time, it also conforms to the trend of low – carbon economy and sustainable development, which is beneficial to promoting the technological progress and environmental protection of the industry.

7. Summary

In this study, an improved semi – forging remnant – heat quenching process for producing bucket teeth was proposed. The critical temperature for completing the pearlite transformation in 40Cr steel was determined to be 650°C through experiments. The mechanical properties of bucket teeth produced by different heat treatment processes were compared, and it was found that the semi – forging remnant – heat quenching process had better impact toughness compared to the forging remnant – heat quenching process and could save energy and working hours compared to the forging conventional quenching process. Future research directions include optimizing process parameters, applying to other steels, evaluating long – term performance, and conducting numerical simulations. The industrial application of this process has significant potential and is of great significance for the development of the bucket teeth manufacturing industry.