Heat treatment is mainly to change the as cast structure of bucket teeth and change the as cast martensite into tempered martensite after heat treatment.

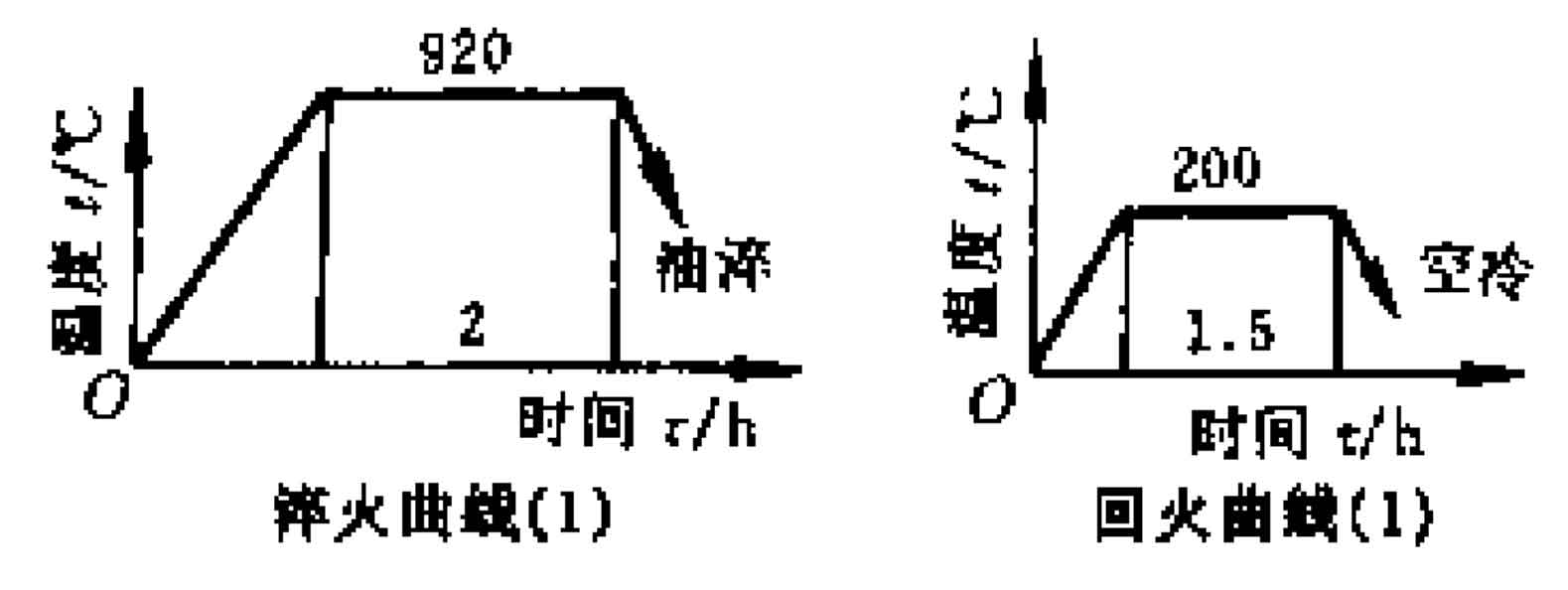

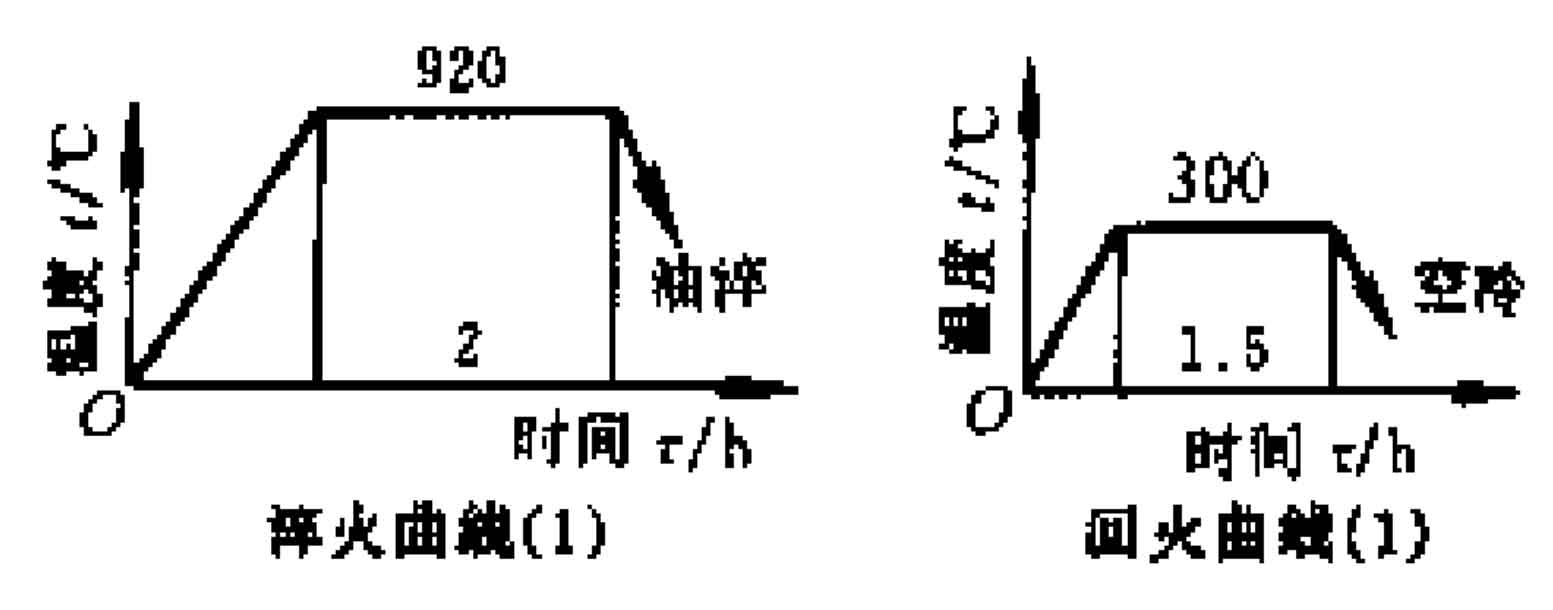

Due to the different stress of the shovel seat and the shovel head in use, there are different requirements for hardness. In order to ensure the wear resistance of the shovel seat, high-temperature quenching is adopted. Low temperature fire (see Figure 1) is adopted for high-temperature quenching of the shovel head and annular clip, which is slightly higher than the temperature of the shovel seat for tempering (see Figure 2). The quenching furnace adopts shallow well furnace and oil quenching, and the tempering furnace adopts well fan tempering furnace.

After many heat treatment tests, the reasonable heat treatment process is finally determined.