Abstract

This article delves into the latest advancements in full-process automation for engine cylinder block casting cleaning, with a focus on improving productivity, reducing labor intensity, and enhancing product quality assurance. By implementing innovative process designs and automation technologies, this transformation lays the foundation for an unmanned cleaning process, thereby boosting the competitiveness of engine casting enterprises. This comprehensive study presents a detailed analysis of automation strategies, equipment integration, and quality control measures, with a special emphasis on engine casting and cleaning automation.

Introduction

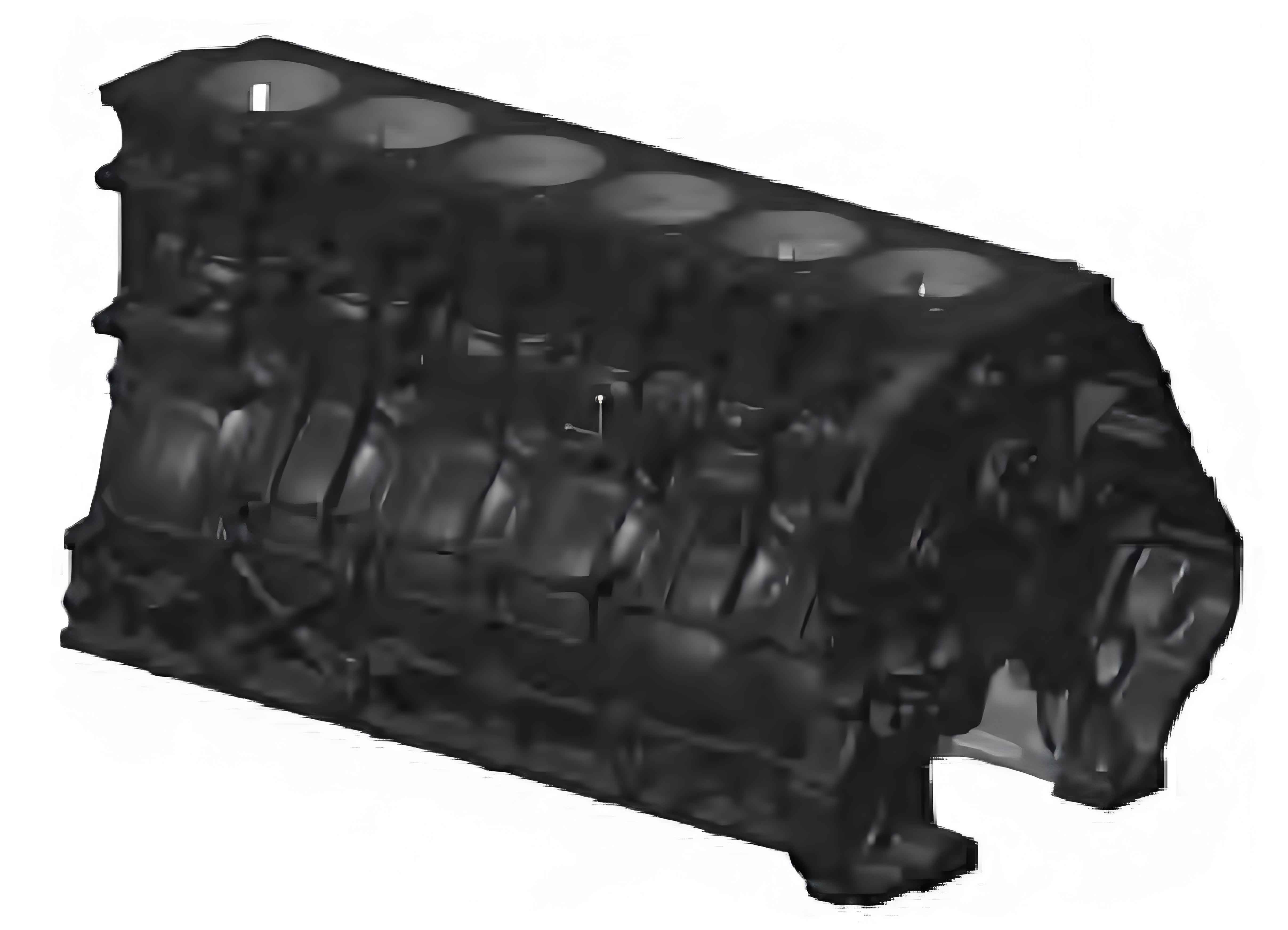

The engine cylinder block, as a critical component of automotive engines, requires rigorous manufacturing processes to ensure optimal performance and durability. Traditional cleaning methods, which often rely heavily on manual labor, have become increasingly inefficient and unreliable, necessitating a shift towards automation. This paper explores the full-process automation of cylinder block casting cleaning, utilizing advanced robotic and vision-guided systems to streamline production and improve quality standards.

1. Overview of Cylinder Block Casting and Cleaning Challenges

Engine cylinder blocks undergo complex casting processes, resulting in intricate structures that pose significant challenges during the cleaning phase. The cleaning process aims to remove residual sand, oxides, and other impurities from the casting surface and internal cavities to ensure the integrity and functionality of the final product. However, traditional cleaning methods, such as manual sandblasting and grinding, are labor-intensive, hazardous, and prone to inconsistencies, resulting in lower product quality and reduced production efficiency.

1.1 Traditional Cleaning Methods

Traditional cleaning methods include:

- Manual Sandblasting: Involves manually directing a stream of abrasive material at the casting surface to remove surface impurities. This method is labor-intensive and often leads to inconsistent cleaning results.

- Hand Grinding: Involves using hand-held grinding tools to remove casting defects and surface imperfections. This process is time-consuming and can damage the casting surface if not performed with precision.

1.2 Challenges with Traditional Methods

- High Labor Intensity: Manual cleaning processes require a significant workforce, leading to increased labor costs and potential health risks for workers.

- Inconsistent Quality: Manual cleaning often results in variations in cleaning quality, affecting the overall reliability of the final product.

- Low Productivity: Traditional methods are time-consuming, limiting production throughput and increasing lead times.

2. Automation Strategies for Cylinder Block Cleaning

To overcome the limitations of traditional cleaning methods, automation strategies have been developed that leverage advanced robotic and vision-guided systems. These automation strategies significantly improve productivity, reduce labor intensity, and enhance product quality assurance.

2.1 Automated Material Handling

Automated material handling systems use robots and conveyors to transport cylinder blocks between various cleaning stations, eliminating the need for manual handling. Vision-guided systems ensure precise positioning and alignment of the castings, reducing the risk of damage during transfer.

2.1.1 Robotic Arms and Grippers

- Robotic Arms: Highly flexible multi-axis robotic arms are utilized to pick up and position cylinder blocks accurately within the cleaning process.

- Custom Grippers: Specially designed grippers are attached to the robotic arms to securely hold the cylinder blocks during transport and positioning.

2.1.2 Conveyor Systems

- Automated Conveyors: Automated roller conveyors transport cylinder blocks between different cleaning stations, maintaining a continuous flow of work.

- Positioning Devices: Positioning devices, such as pneumatic stops and turntables, ensure precise alignment of the cylinder blocks at each cleaning station.

2.2 Automated Cleaning Processes

Automated cleaning processes incorporate a range of technologies, including high-pressure water jets, shot blasting, and robotic grinding, to achieve thorough and consistent cleaning results.

2.2.1 High-Pressure Water Jet Cleaning

- Water Jet Systems: High-pressure water jets are used to remove loose sand and other impurities from the casting surface. These systems are highly effective for preliminary cleaning.

- Water Recycling: Recycled water is used to minimize water consumption and reduce operating costs.

2.2.2 Shot Blasting

- Automated Shot Blasters: Shot blasting machines use a stream of abrasive media (e.g., steel shot or grit) to remove stubborn impurities and smoothen rough surfaces. Automated shot blasters integrate vision systems for precise targeting and control.

- Dust Collection: Integrated dust collection systems minimize airborne particles and maintain a clean work environment.

2.2.3 Robotic Grinding

- Robotic Grinders: Industrial robots equipped with grinding tools are used for precision grinding and finishing of the casting surface.

- Laser Guidance: Some robotic grinding systems utilize laser sensors to detect surface imperfections and adjust the grinding path accordingly, ensuring a smooth and even finish.

2.3 Vision-Guided Systems

Vision-guided systems play a crucial role in automating the cleaning process, providing precise control and real-time feedback.

2.3.1 2D and 3D Vision Systems

- 2D Vision Systems: Utilize 2D cameras to detect and identify cylinder blocks, ensuring proper alignment and positioning during handling and cleaning.

- 3D Vision Systems: 3D cameras provide depth information, enabling robots to navigate complex geometries and adapt to surface variations during grinding and finishing operations.

2.3.2 Object Recognition and Tracking

- Object Recognition: Advanced algorithms enable vision systems to recognize and distinguish between different cylinder block models, facilitating mixed-model production lines.

- Real-Time Tracking: Vision systems continuously track the position and orientation of the cylinder blocks, allowing for precise control of the cleaning process.

3. Automation Benefits and Challenges

3.1 Benefits

- Increased Productivity: Automation significantly reduces cycle times and increases overall production throughput.

- Improved Quality: Consistent cleaning results lead to higher product quality and reliability.

- Reduced Labor Costs: Automation minimizes the need for manual labor, reducing labor costs and mitigating health risks for workers.

- Flexible Production: Automated systems can accommodate mixed-model production lines, enhancing production flexibility.

3.2 Challenges

- High Initial Investment: Implementing automation requires significant upfront investment in equipment and technology.

- Technical Complexity: Automating complex processes requires advanced technological expertise and ongoing maintenance.

- Process Optimization: Fine-tuning automated processes to achieve optimal performance can be time-consuming and resource-intensive.

4. Case Study: Automation of a Heavy Duty Engine Cylinder Block Cleaning Process

To illustrate the benefits of automation, a case study is presented detailing the automation of a heavy-duty engine cylinder block cleaning process.

4.1 Background

A leading engine manufacturer aimed to improve the efficiency and quality of its cylinder block cleaning process. The manufacturer faced significant challenges due to the complex geometries and high production volumes of its cylinder blocks.

4.2 Automation Implementation

The manufacturer implemented a comprehensive automation strategy, encompassing automated material handling, shot blasting, robotic grinding, and vision-guided systems.

4.2.1 Automated Material Handling

- Robotic Arms: Six-axis robotic arms equipped with custom grippers were installed to handle the cylinder blocks between cleaning stations.

- Automated Conveyors: Roller conveyors integrated with positioning devices facilitated seamless transfer of cylinder blocks throughout the cleaning process.

4.2.2 Automated Cleaning Processes

- Shot Blasting: Automated shot blasters, integrated with dust collection systems, removed stubborn impurities from the casting surface.

- Robotic Grinding: Industrial robots equipped with laser-guided grinding tools performed precision grinding and finishing of the cylinder block surface.

4.2.3 Vision-Guided Systems

- 2D and 3D Vision: Vision systems, including 2D and 3D cameras, ensured precise positioning and tracking of the cylinder blocks during cleaning operations.

- Object Recognition: Advanced algorithms enabled the vision systems to distinguish between different cylinder block models, adapting the cleaning process accordingly.

4.3 Results

After implementing the automation strategy, the manufacturer experienced significant improvements:

- Productivity Increase: Production throughput increased by 30%, enabling the manufacturer to meet higher demand.

- Quality Enhancement: Consistent cleaning results led to a 20% reduction in quality defects, enhancing overall product reliability.

- Cost Savings: Reduced labor costs and improved efficiency resulted in substantial cost savings over time.

- Worker Safety: Automation mitigated health risks for workers, creating a safer work environment.

5. Conclusion

The automation of engine cylinder block casting cleaning processes represents a significant advancement in the automotive industry. By leveraging advanced robotic and vision-guided systems, manufacturers can improve productivity, enhance product quality, and reduce labor costs. Although automation requires significant upfront investment and ongoing technical expertise, the benefits far outweigh the challenges. As the automotive industry continues to evolve, the adoption of automation strategies for cylinder block cleaning processes will become increasingly essential for maintaining competitiveness and ensuring optimal product performance.