The cracks of the motor shell are typical thermal cracks. There are more than 40 cracks and more than 80 cracks in each motor shell. Among them, the number of cracks at the fillet of the inner cylinder accounts for 50%, the cracks at the part with excessive wall thickness, the edge of cold iron and the root of riser account for 30%, and other parts account for 20%. Almost every motor shell produced has cracks. If the cracks are serious, they will be directly scrapped. If the cracks are relatively minor and within the scope of welding repair allowed by the standard, they will be repaired by welding repair. The crack problem seriously restricts the production of ZHY casting motor shell.

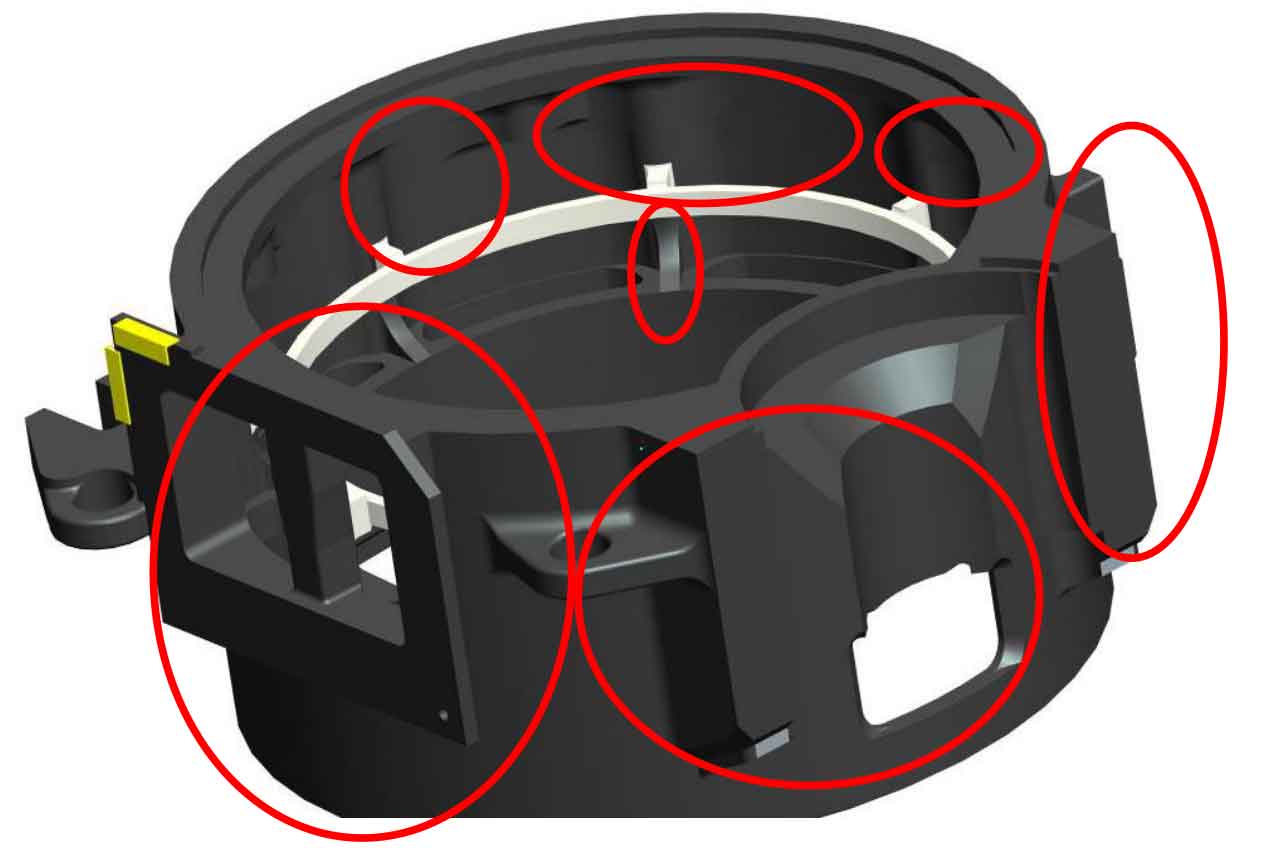

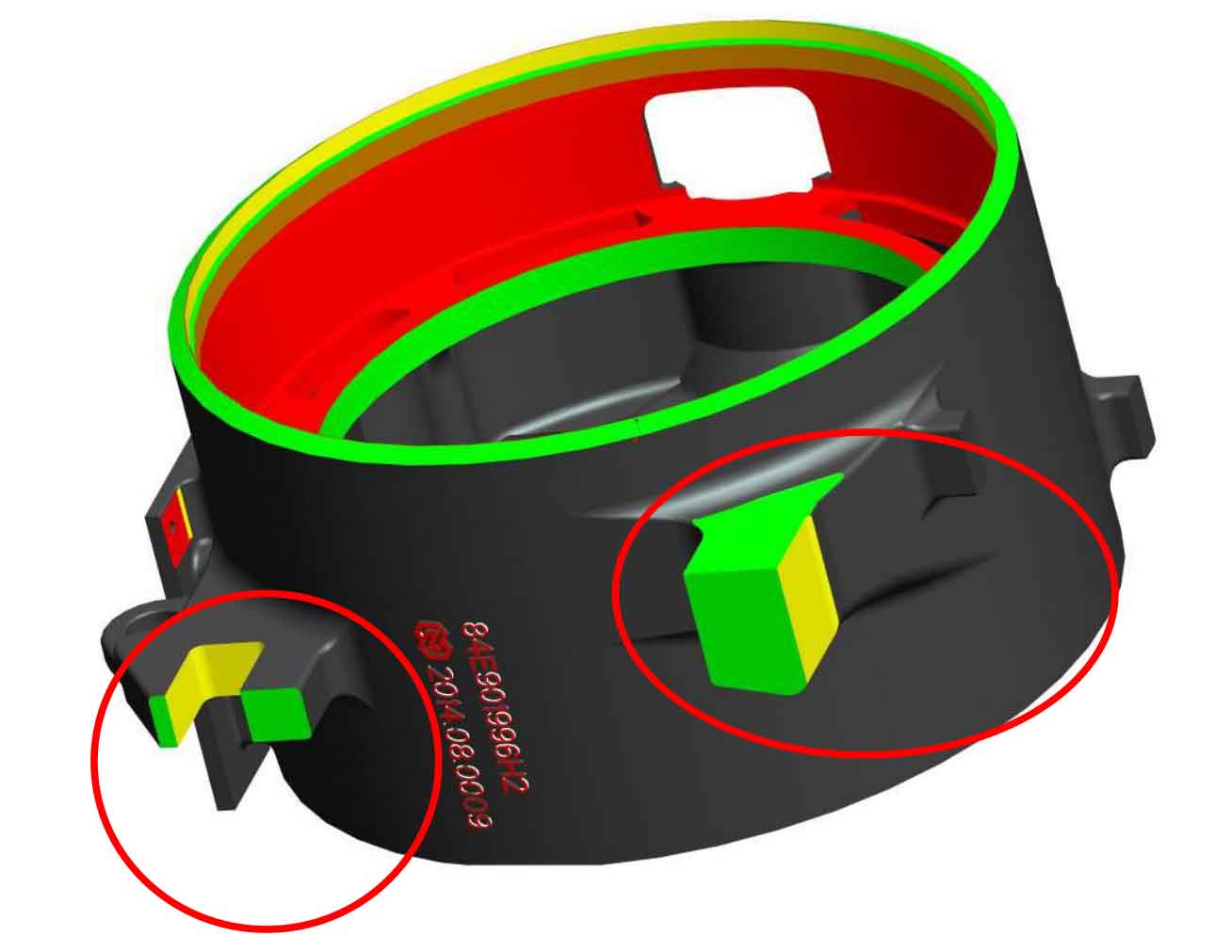

The casting structure of the motor housing is shown in Figure 1 and figure 32. The structure is similar to the thin-walled cylinder, and there are many bosses on the outer cylinder, resulting in many hot spots in the casting; There are several stiffeners on the inner cylinder, and the connecting arc is relatively small; The wall thickness of the cylinder is too large, ranging from 25mm to more than 80mm. These structural features are very unfavorable to the production of the casting process. The position marked by the red circle in the structural diagram of the motor shell is very easy to produce stress concentration during the solidification and shrinkage of the casting, and the tendency of cracks is relatively large.