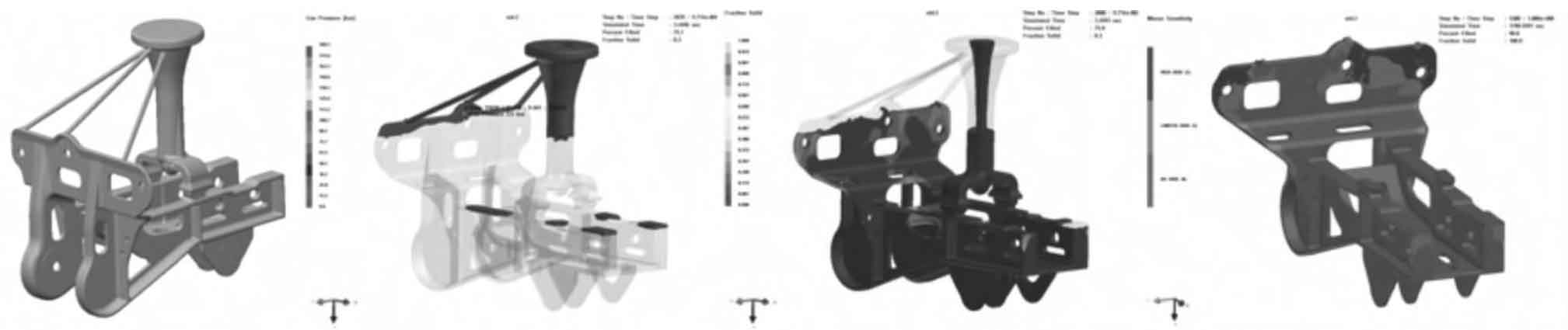

Because the exhaust rib is not set in the original scheme, the simulation shows that the gas pressure in the mold shell of the investment casting steel is close to 45 bar before being filled. Therefore, one of the reasons for the insufficient pouring defect of the investment casting steel may also be caused by “holding air”. In addition, according to the above analysis results, the low actual pouring temperature is also the main reason for the insufficient pouring defect of the investment casting steel. Based on this consideration, the improved scheme adds exhaust ribs on the basis of the original scheme, and the process scheme is shown in the figure. The pouring temperature is set to 1560 ℃, and other parameters are the same as those in the table. Considering the effect of gas model, the improved scheme is simulated and analyzed by momentum coupling analysis method. The gas pressure distribution before the investment casting is filled is shown in Figure B, the solidification condition is shown in Figure C, and the cold shut prediction result is shown in Figure D.

Figure B shows that the gas pressure in the mold shell of investment casting steel before filling is 3.5 bar, which is 41.5 bar lower than that of the scheme without exhaust rib, and the gas is discharged with the exhaust rib, without the risk of insufficient pouring caused by “holding air”; Figure C shows that before the investment casting is filled, the liquid metal at the front end of the mold filling has begun to solidify, and the solid fraction is about 20% ~ 30%; Figure D shows that there is a cold lap area at the filling end of the investment casting, and the cold lap position is basically the same as the casting defect position of the original scheme.

The pouring test of the improved scheme is also carried out. The pouring temperature is 1560 ℃. The test results show that the casting defects are basically not improved. More than 40% of the investment casting steel castings still have insufficient pouring defects, and the location of the casting defects is the same as that of the original scheme; When the pouring temperature is above 1600 ℃, the insufficient pouring defect of investment casting steel is obviously improved, and the proportion of insufficient pouring defect is reduced to less than 10%, but there is still the risk of insufficient pouring, and the process control is difficult.

| Casting material | Shell material | Shell thickness / mm | Shell temperature / ℃ | Pouring temperature / ℃ | Pouring speed / (m · s-1) | Cooling mode | Heat transfer coefficient between casting and shell (/ w · m – · 2 K -) |

| C45E | Silica sand | 8 | 650 | 1540 | 0.38 | Air cooling | 900 |

Therefore, it can be determined that the main reason for the insufficient pouring of investment casting steel is the low pouring temperature and pouring speed. In addition, the design of gating system is unreasonable: the pressure head at the defect position is low, the liquid metal flow distance is long, and the insufficient pouring of investment casting steel. The liquid metal at the defect position is filled from bottom to top, and the liquid metal is cooled too fast, resulting in insufficient pouring defects.