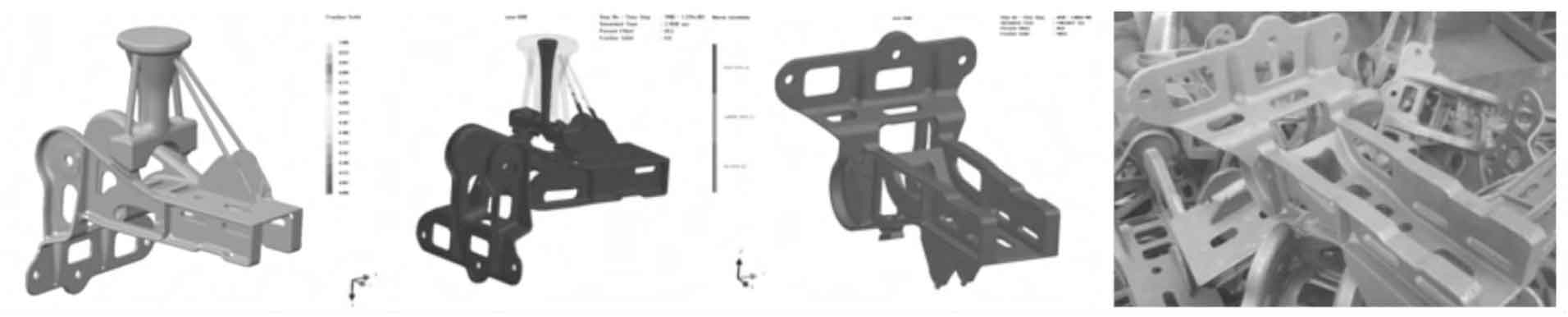

After analyzing the defects, another improvement scheme is made, as shown in the figure. In the original scheme, the investment mold steel castings are inverted, the gating system is placed in the middle of the investment mold steel castings, and most of the investment mold steel castings are located below the gating system. In this way, the filling head is added, and the metal liquid at the defect position is filled from top to bottom, so the filling ability is enhanced. In addition, the actual pouring temperature is increased to 1600 ℃, and the pouring speed is 0.38 M / s.

Using the momentum coupling analysis method and considering the effect of the gas model, except the pouring temperature, other parameters are the same as those in the table. The simulation analysis of the improved scheme is carried out. The mold filling and solidification is shown in Figure b, the cold lap prediction result is shown in Figure c, and the physical verification result is shown in Figure d.

Figure B shows that the investment casting has no solidification before filling, and figure c shows that the investment casting has no cold shut risk. The pouring test of the improved scheme is also carried out: the pouring temperature is 1600 ℃ and the pouring speed is 0.38 M / s. The test results show that there is no insufficient pouring defect of investment casting steel. After batch verification, the proportion of insufficient pouring defect of investment casting steel is stable within 2%, and the improvement effect is obvious.