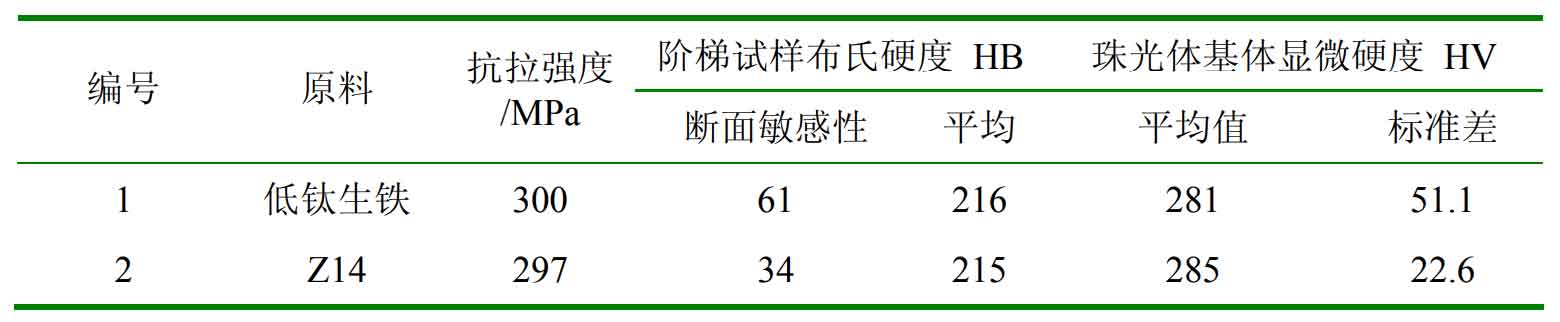

The mechanical properties of samples melted and poured with different pig iron are shown in the table. It can be seen from the table that the tensile strength of gray cast iron samples treated with two different raw materials is basically the same, reaching the HT300 standard. There is little difference in Brinell hardness and microhardness between the two samples, but the section sensitivity and microhardness standard deviation change greatly.

From the table, it can be seen that the section sensitivity of low titanium pig iron smelting sample Δ Hb is 61 Hb. Section sensitivity of z14 melted sample Δ Hb is only 34 Hb. The hardness of z14 melted gray cast iron is less affected by the change of wall thickness, and the section sensitivity of its sample is better than that of low titanium pig iron. In pig iron, due to the coexistence of alloy element titanium and silicon, the white mouth phenomenon of low titanium pig iron is serious. The heredity of gray cast iron is great in melting. Although the iron in the experiment was left standing at high temperature before pouring, its section sensitivity is still great. The microhardness of pearlite matrix of samples treated with different treatments is equal. From the standard deviation of indentation, it can be seen that the micro indentation diameter of the sample treated with low titanium pig iron fluctuates widely, and the micro hardness of the matrix is uneven. The microhardness fluctuation range of z14 melted sample is small, and its microhardness uniformity is better than that of low titanium pig iron.