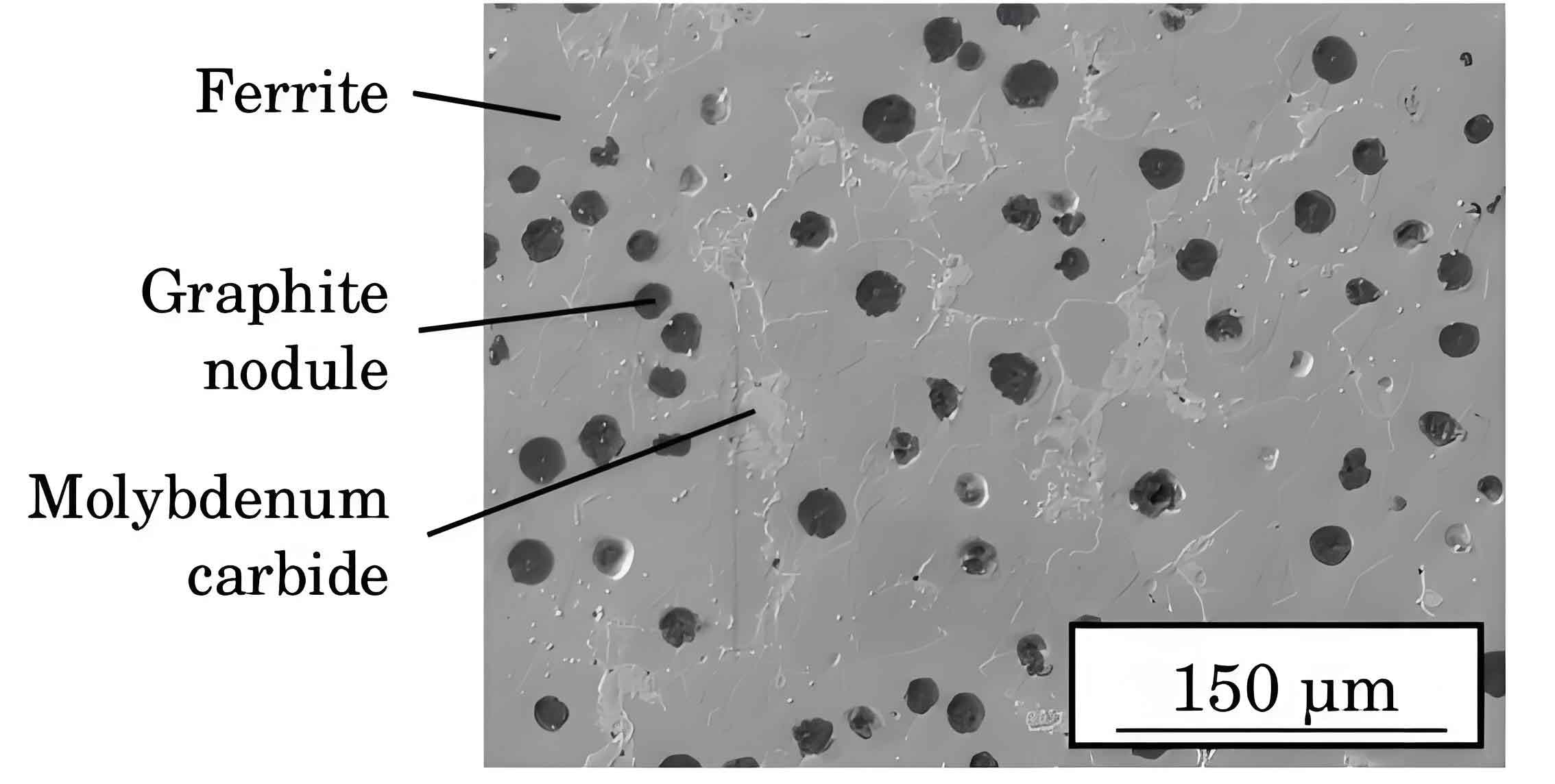

Spheroidal graphite iron castings have revolutionized the engineering industry with its exceptional mechanical properties. This type of iron features spheroidal graphite inclusions, which give it a unique combination of high strength, ductility, and resistance to wear and fatigue. These properties make spheroidal graphite iron castings an ideal material for a wide range of modern engineering applications. This article explores various innovative uses of spheroidal graphite iron castings in contemporary engineering, highlighting specific applications, benefits, and future trends. Tables and lists are included to provide a comprehensive understanding.

Introduction

Spheroidal graphite iron castings’s versatility has enabled its widespread adoption across various sectors, including automotive, aerospace, construction, and energy. Its superior mechanical properties, coupled with its cost-effectiveness and ease of production, make it a preferred choice for many critical components. This article delves into some of the most innovative applications of SG iron castings in modern engineering.

Automotive Industry

The automotive industry has greatly benefited from the use of spheroidal graphite iron castings due to their high strength-to-weight ratio, excellent wear resistance, and good machinability.

- Engine Components:

- Crankshafts: spheroidal graphite iron castings crankshafts offer superior fatigue resistance, ensuring long service life under high-stress conditions.

- Cylinder Heads: Improved thermal conductivity and resistance to thermal fatigue enhance engine efficiency and durability.

- Suspension Systems:

- Control Arms: High strength and ductility ensure reliable performance and safety.

- Steering Knuckles: Excellent wear resistance and fatigue strength improve vehicle handling and durability.

Aerospace Industry

In the aerospace sector, the demand for lightweight, high-strength materials has driven the adoption of spheroidal graphite iron castings in various components.

- Landing Gear Components:

- Struts and Supports: High impact resistance and durability under extreme conditions ensure safe landings and take-offs.

- Gear Housings: Lightweight and strong, providing excellent support without adding unnecessary weight.

- Engine Components:

- Turbocharger Housings: High thermal resistance and strength improve engine performance and longevity.

- Exhaust Manifolds: Enhanced resistance to thermal cycling reduces the risk of cracking and deformation.

Construction and Infrastructure

Spheroidal graphite iron castings’s robustness and resistance to environmental factors make it ideal for construction and infrastructure applications.

- Pipes and Fittings:

- Water and Sewage Systems: High corrosion resistance ensures long service life in harsh environments.

- Gas Pipelines: Excellent pressure resistance and toughness provide reliable performance under high stress.

- Structural Components:

- Bridge Bearings: High load-bearing capacity and flexibility accommodate structural movements and loads.

- Building Frames: Enhanced strength and ductility ensure structural integrity and safety.

Energy Sector

The energy sector, particularly renewable energy, has leveraged spheroidal graphite iron castings’s properties for various applications.

- Wind Turbine Components:

- Hub and Housing: High fatigue strength and corrosion resistance ensure long-term performance and reliability.

- Gearbox Components: Excellent wear resistance and strength improve efficiency and lifespan.

- Hydropower Components:

- Turbine Runners: High impact resistance and durability in water environments enhance performance and longevity.

- Valve Bodies: Excellent corrosion resistance and strength ensure reliable operation and minimal maintenance.

Table: Innovative Applications of Spheroidal Graphite Iron Castings

| Industry | Component | Benefits |

|---|---|---|

| Automotive | Crankshafts | Superior fatigue resistance, long service life |

| Cylinder Heads | Improved thermal conductivity, thermal fatigue resistance | |

| Aerospace | Landing Gear Struts | High impact resistance, durability under extreme conditions |

| Turbocharger Housings | High thermal resistance, strength | |

| Construction | Water Pipes | High corrosion resistance, long service life |

| Bridge Bearings | High load-bearing capacity, flexibility | |

| Energy | Wind Turbine Hubs | High fatigue strength, corrosion resistance |

| Turbine Runners | High impact resistance, durability in water environments |

Future Trends and Innovations

As technology advances, the applications of spheroidal graphite iron castings continue to expand. Some future trends and innovations include:

- 3D Printing and Additive Manufacturing:

- Customized Components: Tailored properties and geometries for specific applications, improving performance and reducing material waste.

- Rapid Prototyping: Faster development cycles and reduced time-to-market for new products.

- Nanotechnology:

- Enhanced Material Properties: Incorporation of nanoparticles to improve strength, wear resistance, and thermal properties.

- Self-Healing Materials: Development of spheroidal graphite iron castings with self-healing capabilities to extend service life and reduce maintenance.

- Sustainability:

- Recycling and Reusability: Increased focus on recycling spheroidal graphite iron castings components to reduce environmental impact and improve sustainability.

- Eco-Friendly Production: Adoption of greener manufacturing processes to minimize carbon footprint.

List: Future Trends and Innovations in Spheroidal Graphite Iron Castings

- 3D Printing and Additive Manufacturing:

- Customized components

- Rapid prototyping

- Nanotechnology:

- Enhanced material properties

- Self-healing materials

- Sustainability:

- Recycling and reusability

- Eco-friendly production

Conclusion

The innovative applications of spheroidal graphite iron castings in modern engineering are vast and varied. From automotive and aerospace to construction and energy, spheroidal graphite iron castings continues to prove its worth as a versatile and high-performance material. As advancements in technology and materials science continue to emerge, the future holds even greater potential for spheroidal graphite iron castings in engineering applications. By embracing these innovations and trends, industries can achieve new levels of performance, efficiency, and sustainability.