Spheroidal graphite iron (SG iron), also known as ductile iron, is renowned for its excellent mechanical properties, which make it suitable for a wide range of applications, especially in the automotive and heavy machinery industries. Heat treatment processes play a crucial role in enhancing the properties of spheroidal graphite iron, making it more durable and reliable. This article delves into innovative heat treatment processes for spheroidal graphite iron, highlighting their impact on the material’s performance.

Introduction

Heat treatment is a controlled process used to alter the physical and mechanical properties of materials without changing their shapes. In the case of spheroidal graphite iron, heat treatment can significantly enhance properties such as strength, toughness, ductility, and wear resistance. Traditional heat treatment methods include annealing, normalizing, and quenching and tempering. However, recent advancements have led to the development of more innovative techniques that offer superior results.

Properties of Spheroidal Graphite Iron

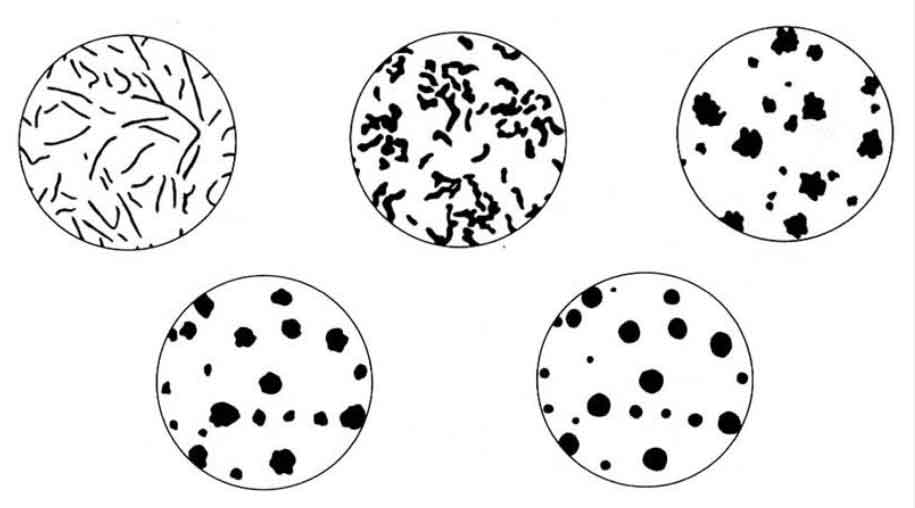

spheroidal graphite iron is characterized by its spherical graphite nodules, which improve its mechanical properties compared to traditional cast iron. The key properties of spheroidal graphite iron include:

- High Tensile Strength: The ability to withstand substantial stress without breaking.

- Excellent Ductility: Flexibility that reduces the likelihood of cracking under impact.

- Good Fatigue Resistance: Enhanced lifespan under cyclic loading conditions.

- Superior Wear Resistance: Reduced wear and tear in high-contact applications.

Table 1: Key Properties of Spheroidal Graphite Iron

| Property | Value |

|---|---|

| Tensile Strength | 600 – 900 MPa |

| Yield Strength | 350 – 600 MPa |

| Elongation | 10 – 18% |

| Hardness | 150 – 300 HB |

| Fatigue Strength | High (similar to steels) |

Innovative Heat Treatment Processes

1. Austempering

Austempering is a heat treatment process that involves heating the spheroidal graphite iron to a temperature above the transformation range, then cooling it rapidly in a salt bath maintained at a lower temperature. This process results in a microstructure known as bainite, which combines high strength and ductility.

Benefits of Austempering:

- Enhanced strength and toughness

- Improved wear resistance

- Increased fatigue strength

Table 2: Properties of Austempered Spheroidal Graphite Iron

| Property | Value |

|---|---|

| Tensile Strength | 900 – 1200 MPa |

| Yield Strength | 650 – 850 MPa |

| Elongation | 5 – 12% |

| Hardness | 300 – 450 HB |

| Fatigue Strength | Very High |

2. Carburizing

Carburizing is a surface hardening process that involves diffusing carbon into the surface layer of the spheroidal graphite iron. This is achieved by heating the iron in a carbon-rich environment. The result is a hard, wear-resistant surface layer, while the core remains ductile.

Benefits of Carburizing:

- Increased surface hardness

- Enhanced wear resistance

- Improved fatigue strength

3. Induction Hardening

Induction hardening uses electromagnetic induction to heat the surface of the spheroidal graphite iron rapidly. The heated surface is then quenched, leading to a hard martensitic layer. This process is highly controllable and can be localized to specific areas.

Benefits of Induction Hardening:

- Precise control over hardened areas

- Enhanced surface hardness

- Improved wear resistance

4. Laser Surface Hardening

Laser surface hardening involves using a high-power laser to heat the surface of the spheroidal graphite iron. The rapid heating and subsequent cooling create a hardened layer with improved wear resistance and fatigue strength.

Benefits of Laser Surface Hardening:

- High precision and control

- Minimal distortion

- Enhanced surface properties

5. Cryogenic Treatment

Cryogenic treatment involves cooling spheroidal graphite iron to extremely low temperatures, typically using liquid nitrogen. This process refines the microstructure and can enhance mechanical properties such as toughness and wear resistance.

Benefits of Cryogenic Treatment:

- Improved wear resistance

- Enhanced toughness

- Increased dimensional stability

Table 3: Comparison of Innovative Heat Treatment Processes

| Process | Strength Improvement | Wear Resistance | Fatigue Strength | Precision Control |

|---|---|---|---|---|

| Austempering | High | High | High | Moderate |

| Carburizing | Moderate | Very High | High | Moderate |

| Induction Hardening | Moderate | High | High | High |

| Laser Hardening | Moderate | High | High | Very High |

| Cryogenic Treatment | Moderate | Moderate | Moderate | High |

Applications in Automotive Industry

1. Engine Components

Spheroidal graphite iron is extensively used in engine components such as crankshafts, camshafts, and cylinder heads. Heat treatment processes like austempering and induction hardening enhance the strength and wear resistance of these components, ensuring they withstand high stresses and temperatures.

2. Transmission Gears

Transmission gears require materials with high surface hardness and fatigue strength. Carburizing and induction hardening are commonly used to achieve these properties, resulting in gears that are durable and reliable under high-load conditions.

3. Suspension Parts

Suspension parts such as control arms and stabilizer bars benefit from the toughness and wear resistance provided by heat-treated spheroidal graphite iron. These components are critical for vehicle stability and safety.

Case Study: Austempered Ductile Iron Gears

A study on the use of austempered ductile iron (ADI) for automotive gears demonstrated significant improvements in performance and durability. The ADI gears exhibited higher tensile strength, wear resistance, and fatigue strength compared to traditionally treated gears, leading to extended service life and reduced maintenance costs.

Table 4: Performance Comparison of ADI and Traditional Gears

| Property | ADI Gears | Traditional Gears |

|---|---|---|

| Tensile Strength | 1100 MPa | 700 MPa |

| Wear Resistance | High | Moderate |

| Fatigue Strength | Very High | High |

| Service Life | Extended | Standard |

Future Trends in Heat Treatment of Spheroidal Graphite Iron

The future of heat treatment for spheroidal graphite iron looks promising, with ongoing research focused on further enhancing its properties and performance. Key trends include:

1. Integration of Nanotechnology

Incorporating nanomaterials into heat treatment processes can refine the microstructure of spheroidal graphite iron, leading to improved mechanical properties. This advancement could result in even more durable and high-performance components.

2. Development of Eco-Friendly Processes

The push for sustainability is driving the development of eco-friendly heat treatment processes. Techniques that reduce energy consumption and minimize environmental impact are being explored to achieve greener manufacturing practices.

3. Advanced Monitoring and Control

The integration of smart manufacturing technologies, such as the Internet of Things (IoT) and artificial intelligence (AI), into heat treatment processes allows for real-time monitoring and control. These technologies enable precise adjustments and ensure consistent quality.

Conclusion

Innovative heat treatment processes have significantly enhanced the properties and performance of spheroidal graphite iron, making it an even more valuable material for automotive applications. Through techniques such as austempering, carburizing, induction hardening, laser surface hardening, and cryogenic treatment, spheroidal graphite iron components achieve superior strength, wear resistance, and fatigue strength. As research and development continue, the automotive industry can look forward to further advancements in spheroidal graphite iron, ensuring the production of durable, high-performance components that meet the evolving demands of modern vehicles.