1. Introduction

In the dynamic world of pipeline equipment manufacturing, Hebei Yadu Pipeline Equipment Group Co., Ltd. has emerged as a frontrunner. Located in Mengcun Hui Autonomous County, Hebei Province, the company specializes in the production and sales of a wide range of pipeline products, including steel elbows, bends, tees, crosses, flanges, and piping. With its advanced technology and high-quality products, Hebei Yadu has established a strong foothold in the market and has become a trusted supplier to leading enterprises in industries such as petroleum, chemical, gas, power, boilers, and heating.

2. Company Profile and Technological Advantages

2.1 Product Range and Market Position

Hebei Yadu’s product portfolio is extensive, covering various types of pipeline components. Their steel elbows and bends are designed to meet the demanding requirements of different industries, ensuring efficient fluid transportation. The company’s tees, crosses, flanges, and piping systems are also known for their durability and reliability. This comprehensive product range has enabled Hebei Yadu to serve a diverse customer base and maintain a competitive edge in the market.

2.2 Technological Innovation and Industry Recognition

The company’s commitment to technological innovation has been a key driver of its success. By investing in research and development, Hebei Yadu has achieved significant breakthroughs in production processes. Their expertise in manufacturing high-temperature, high-pressure, thick-walled, large-diameter alloy steel and stainless steel pipe fittings has set them apart from competitors. As a result, the company has been recognized as a high-tech enterprise in Hebei Province and a model of specialization, refinement, uniqueness, and innovation.

3. Research and Innovation in Pipeline Casting Process

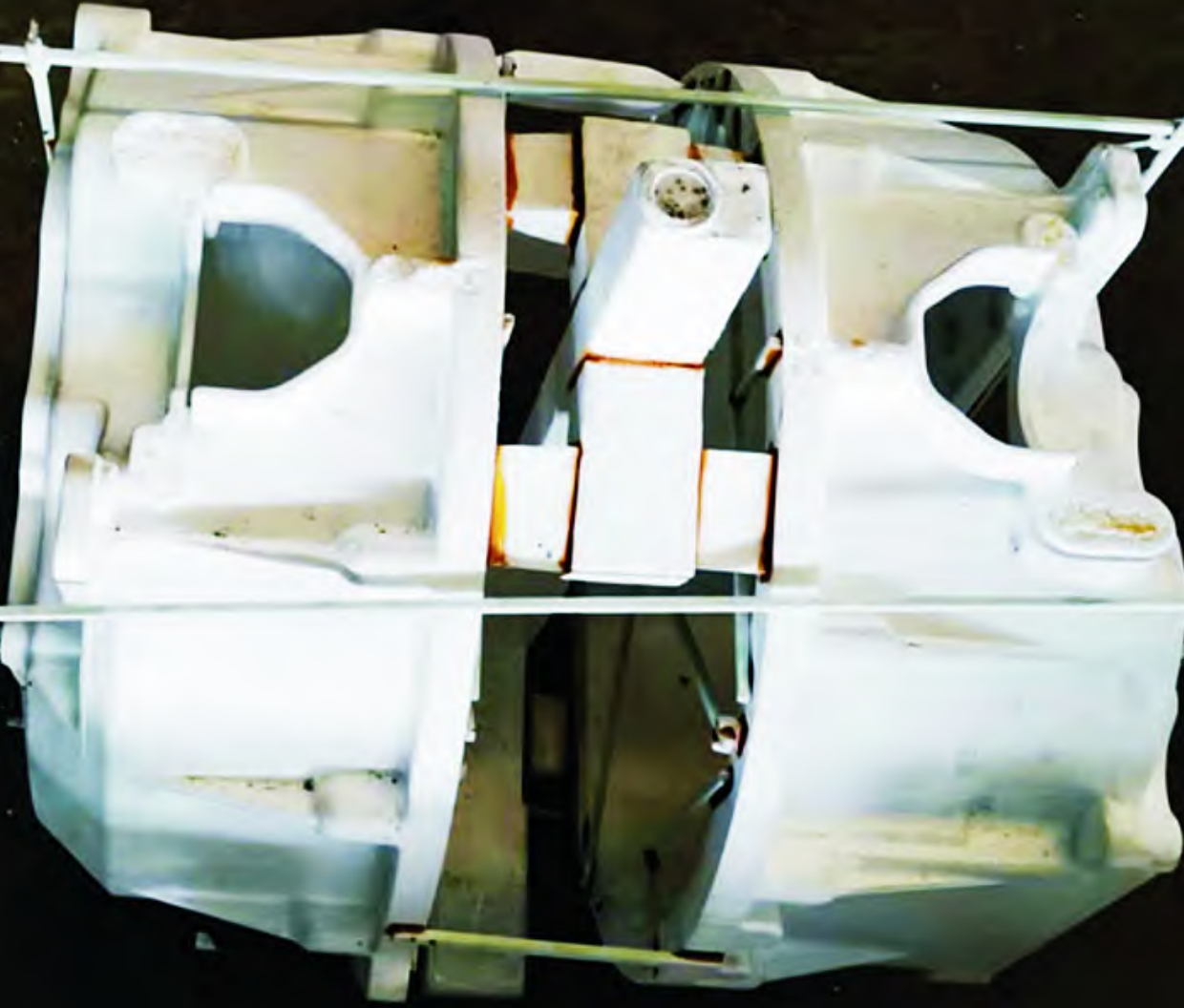

3.1 Improvement of Push-bending Mandrel for Elbows

3.1.1 Problem Identification

In the production of elbows, the push-bending mandrel, traditionally made of high-alloy stainless steel, posed several challenges. The high cost of manufacturing these mandrels and their susceptibility to damage after a certain period of use were major concerns for the company. Additionally, the occurrence of mandrel breakage during the production of thick-walled elbows was a significant issue that affected production efficiency and cost.

3.1.2 Research and Experimentation

To address these problems, Hebei Yadu’s technical team embarked on a series of research and experimentation. They focused on exploring alternative materials and manufacturing processes that could enhance the performance and durability of the mandrels. After extensive trials, the team discovered that the solid solution heat treatment process, which involves rapid cooling in water from a high-temperature state, could significantly improve the metallographic structure of the stainless steel mandrel.

3.1.3 Results and Benefits

The implementation of the solid solution heat treatment process led to remarkable improvements. The treated mandrels exhibited enhanced tensile and impact resistance, ensuring better performance during the elbow pushing process. Moreover, the service life of the mandrels was extended by more than 100%, reducing the frequency of replacements. This innovation not only saved the company approximately 2.5 million yuan annually in mandrel costs but also increased production efficiency and product quality.

3.2 Segmented Heat Treatment Process for P91 High Alloy Steel Pipes

3.2.1 Challenges in P91 Steel Pipe Processing

P91 high alloy steel is widely used in power plant main steam pipelines due to its excellent high-temperature strength and creep resistance. However, the traditional heat treatment process often resulted in coarse grain size and uneven hardness in the pipes, leading to reduced mechanical properties and potential safety hazards.

3.2.2 Development of the Segmented Heat Treatment Process

To overcome these challenges, Hebei Yadu’s R&D center conducted in-depth research and developed a segmented heat treatment process. This innovative approach involved carefully controlling the heating and cooling rates at different stages of the heat treatment process. By optimizing the temperature and time parameters, the team was able to achieve a more uniform microstructure and improved mechanical properties in the P91 steel pipes.

3.2.3 Impact on Product Quality and Performance

The application of the segmented heat treatment process had a significant impact on the quality and performance of P91 steel pipes. The treated pipes exhibited finer grain size, smaller grain size difference, and more uniform hardness, enhancing their resistance to high-temperature creep and fatigue. This not only improved the reliability and safety of the power plant pipelines but also reduced the scrap rate of products during production, resulting in substantial cost savings and energy conservation.

4. Innovation in Other Aspects of the Company

4.1 Business Philosophy Transformation

Hebei Yadu has recognized the importance of innovation in all aspects of its operations. The company has shifted its business philosophy from traditional manufacturing to a more customer-centric and technology-driven approach. This transformation has enabled them to better understand customer needs and market trends, leading to the development of more innovative and competitive products.

4.2 Production Process Optimization

In addition to the improvements in pipeline casting, the company has also focused on optimizing other production processes. By implementing advanced manufacturing technologies and automation systems, Hebei Yadu has increased production efficiency, reduced labor costs, and improved product quality consistency. These efforts have further strengthened the company’s position in the market.

4.3 Technical Talent Cultivation

To support its innovation initiatives, Hebei Yadu has placed great emphasis on cultivating technical talent. The company has established a comprehensive training system that provides employees with opportunities for professional development and skill enhancement. By attracting and retaining top-notch technical personnel, Hebei Yadu has built a strong R&D team capable of driving continuous innovation.

5. Partnerships and Collaborative Innovation

5.1 University-Enterprise Cooperation

Hebei Yadu has actively pursued partnerships with universities and research institutes to enhance its R&D capabilities. Through collaboration with leading academic institutions, the company has been able to access the latest research findings and technological expertise. Joint research projects have been established to address key technical challenges in the pipeline equipment industry.

5.2 Establishment of Research Centers

In addition to university partnerships, Hebei Yadu has also established its own research centers. The Hebei Alloy Pipeline Fittings Technology Innovation Center and the Ultra-high Pressure Fittings Hebei Engineering Research Center have been set up to focus on the development of advanced pipeline technologies. These centers serve as platforms for industry-university-research cooperation and have played a crucial role in promoting innovation and technological progress in the region.

5.3 Research Directions and Achievements

The research centers at Hebei Yadu have defined three main research directions: ultra-high pressure and alloy pipeline fittings structure design technology, forming process technology, and welding and heat treatment technology. Through continuous efforts in these areas, the company has achieved a series of technological breakthroughs. These include the development of new materials with enhanced performance, improved manufacturing processes for complex pipe fittings, and advanced welding and heat treatment techniques. The resulting innovations have not only enhanced the company’s product competitiveness but have also contributed to the overall development of the pipeline equipment industry.

6. Future Outlook and Sustainable Development

6.1 Commitment to Innovation-Driven Growth

Looking ahead, Hebei Yadu remains committed to innovation as the driving force for its future development. The company plans to further increase its investment in R&D to explore new technologies and products. By leveraging its technological advantages and innovation capabilities, Hebei Yadu aims to expand its market share and strengthen its position as a leading player in the pipeline equipment industry.

6.2 Advancement Towards High-End, Intelligent, and Green Manufacturing

In line with the industry trends, Hebei Yadu is focused on promoting the high-end, intelligent, and green transformation of its manufacturing processes. The company is investing in advanced manufacturing technologies such as automation, robotics, and digitalization to improve production efficiency and product quality. At the same time, efforts are being made to reduce energy consumption and environmental impact through the adoption of sustainable manufacturing practices.

6.3 Industry Leadership and Social Responsibility

As a leading enterprise in the pipeline equipment manufacturing industry, Hebei Yadu is aware of its social responsibility. The company is committed to providing high-quality products and services that meet the needs of customers and contribute to the development of the industry. By driving innovation and promoting sustainable development, Hebei Yadu aims to set an example for other companies in the region and contribute to the economic growth and social progress of the community.

7. Case Studies and Success Stories

7.1 Project A: Large-Diameter Pipeline Installation in an Oil Refinery

In a recent project with a major oil refinery, Hebei Yadu was tasked with supplying and installing a large-diameter pipeline system for crude oil transportation. The project required high-quality pipe fittings that could withstand the harsh operating conditions and ensure the safety and reliability of the pipeline.

Hebei Yadu’s innovative pipeline casting process and advanced manufacturing technologies enabled them to produce custom-designed elbows, tees, and flanges that met the strict specifications of the project. The use of the improved push-bending mandrel and segmented heat treatment process for P91 high alloy steel pipes ensured the excellent mechanical properties and durability of the fittings.

During the installation process, Hebei Yadu’s experienced engineering team worked closely with the refinery’s operations and maintenance personnel to ensure a seamless integration of the pipeline system. The project was completed on time and within budget, and the pipeline has been operating smoothly ever since, with no reported incidents of leakage or failure. This success story has further enhanced Hebei Yadu’s reputation in the oil and gas industry and has led to more business opportunities with other major players in the sector.

7.2 Project B: Power Plant Steam Pipeline Upgrade

A power plant was in need of upgrading its steam pipeline system to improve energy efficiency and meet the increasing demand for electricity. Hebei Yadu was selected as the preferred supplier due to its expertise in manufacturing high-temperature, high-pressure pipe fittings.

The company’s R&D team worked closely with the power plant’s engineers to develop a customized solution using their latest technological advancements. The segmented heat treatment process for P91 steel pipes was applied to ensure the pipes had the required mechanical properties and resistance to creep and fatigue. Additionally, Hebei Yadu provided on-site technical support during the installation and commissioning of the pipeline system.

After the upgrade, the power plant reported a significant improvement in steam flow and energy efficiency. The new pipeline system also exhibited enhanced reliability, reducing the need for frequent maintenance and downtime. This project not only demonstrated Hebei Yadu’s technical capabilities but also its ability to deliver turnkey solutions that meet the specific needs of customers in the power generation industry.

8. Industry Trends and Hebei Yadu’s Adaptation

8.1 Global Demand for High-Performance Pipelines

The global demand for high-performance pipelines is on the rise, driven by the growth of industries such as oil and gas, petrochemicals, and power generation. These industries require pipelines that can withstand extreme temperatures, pressures, and corrosive environments. Hebei Yadu is well-positioned to meet this demand with its continuous innovation in pipeline casting and manufacturing technologies.

The company’s focus on research and development has enabled them to develop new materials and alloys that offer superior mechanical properties and corrosion resistance. Their advanced manufacturing processes ensure the production of high-quality pipe fittings with precise dimensions and excellent surface finishes. By staying at the forefront of technological advancements, Hebei Yadu is able to supply pipelines that meet the stringent requirements of international standards and customer specifications.

8.2 Technological Advancements in Pipeline Manufacturing

The pipeline manufacturing industry is witnessing rapid technological advancements, including the use of automation, artificial intelligence, and digitalization. Hebei Yadu is actively embracing these trends to enhance its production efficiency and product quality.

The company has introduced automated production lines that can handle complex manufacturing processes with high precision and repeatability. This has not only reduced labor costs but also minimized the risk of human errors. Additionally, Hebei Yadu is exploring the use of artificial intelligence in quality control and predictive maintenance. By analyzing data from sensors and production processes, the company can identify potential defects and equipment failures in advance, enabling proactive measures to be taken.

Digitalization is also playing a crucial role in Hebei Yadu’s operations. The company has implemented a comprehensive enterprise resource planning (ERP) system that integrates all aspects of its business, from production planning and inventory management to sales and customer service. This has improved information flow and decision-making, leading to better overall business performance.

8.3 Sustainability and Environmental Considerations

In response to the growing global focus on sustainability, the pipeline manufacturing industry is increasingly emphasizing environmental considerations. Hebei Yadu is committed to reducing its environmental footprint through various initiatives.

The company has invested in energy-efficient manufacturing equipment and processes to minimize energy consumption. They have also implemented waste reduction and recycling programs to manage production waste more effectively. In addition, Hebei Yadu is exploring the use of environmentally friendly materials and coatings that can reduce the impact of pipelines on the environment during their lifecycle.

By integrating sustainability into its business strategy, Hebei Yadu is not only meeting regulatory requirements but also appealing to environmentally conscious customers. This proactive approach is expected to contribute to the long-term viability and competitiveness of the company in the global market.

9. Conclusion

Hebei Yadu Pipeline Equipment Group Co., Ltd. has established itself as a leader in the pipeline manufacturing industry through its continuous innovation and commitment to quality. The company’s success in improving the pipeline casting process, its strategic partnerships with universities and research institutes, and its ability to adapt to industry trends have all contributed to its growth and success.

With a focus on high-end, intelligent, and green manufacturing, Hebei Yadu is well-positioned to meet the future challenges and opportunities in the global market. The company’s case studies and success stories demonstrate its capabilities in delivering high-quality products and solutions that meet the specific needs of customers in various industries.

As the industry continues to evolve, Hebei Yadu will continue to invest in research and development, embrace technological advancements, and prioritize sustainability. By doing so, the company will not only enhance its own competitiveness but also contribute to the overall development and innovation of the pipeline equipment manufacturing industry. The future looks bright for Hebei Yadu as it continues to lead the way in pipeline technology and manufacturing excellence.