Introduction

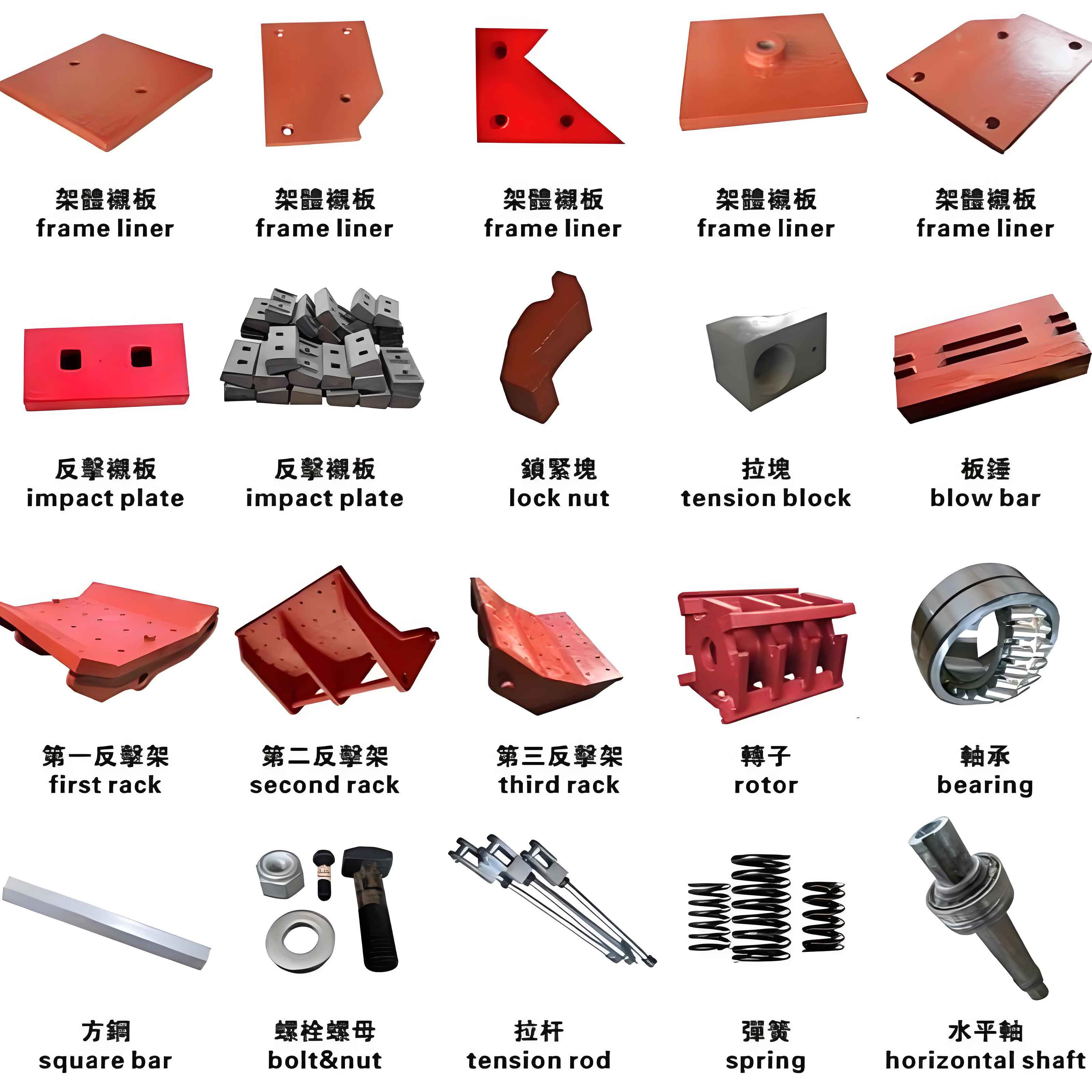

Blow bar is crucial components in impact crushers used across various industries such as mining, quarrying, and recycling. These components endure extreme wear and impact, making their durability and performance critical for efficient operation. To ensure blow bar meet the rigorous demands of their applications, innovative testing methods are essential. This article explores cutting-edge testing techniques designed to evaluate the durability and performance of blow bar, highlighting their benefits, methodologies, and real-world applications.

Importance of Testing Blow Bar

Testing blow bar is essential to verify their ability to withstand high-impact forces and abrasive conditions. Effective testing methods help manufacturers and operators ensure that blow bar is durable, reliable, and capable of maintaining optimal performance over extended periods.

Key Objectives of Blow Bar Testing:

- Durability Assessment:

- Evaluating the wear resistance and longevity of blow bar under operational conditions.

- Performance Evaluation:

- Measuring the efficiency and effectiveness of blow bar in crushing and fragmenting materials.

- Quality Control:

- Ensuring consistency in manufacturing processes and material properties.

Innovative Testing Methods

Advancements in testing technologies have led to the development of several innovative methods for assessing blow bar durability and performance. These methods provide comprehensive insights into the mechanical properties and operational behavior of blow bar.

1. Hardness Testing

Hardness testing measures the resistance of blow bar to deformation and wear. It is a fundamental test to assess the material’s ability to withstand abrasive conditions.

Common Hardness Testing Methods:

- Rockwell Hardness Test:

- Measures the depth of penetration of an indenter under a large load compared to the penetration made by a preload.

- Advantages: Quick, simple, and provides consistent results.

- Applications: Suitable for a variety of materials including steel blow bar.

- Brinell Hardness Test:

- Uses a hardened steel or carbide ball indenter to measure the diameter of the indentation left on the material surface.

- Advantages: Suitable for testing materials with coarse or uneven grain structures.

- Applications: Ideal for testing blow bar made of high manganese steel.

- Vickers Hardness Test:

- Utilizes a diamond pyramid indenter to measure the diagonal length of the indentation.

- Advantages: Provides detailed and precise hardness measurements.

- Applications: Suitable for thin blow bar samples and fine-grained materials.

| Method | Principle | Advantages | Applications |

|---|---|---|---|

| Rockwell Hardness Test | Depth of penetration measurement | Quick, simple, consistent results | Various materials including steel blow bar |

| Brinell Hardness Test | Diameter of indentation measurement | Suitable for coarse/uneven grain structures | High manganese steel blow bar |

| Vickers Hardness Test | Diagonal length of indentation | Detailed, precise measurements | Thin blow bar samples, fine-grained materials |

2. Impact Testing

Impact testing determines the blow bar’s ability to absorb energy and resist fracturing under sudden loads. This test is crucial for understanding how blow bar will perform under the high-impact forces they encounter in service.

Common Impact Testing Methods:

- Charpy Impact Test:

- Measures the energy absorbed by a material during fracture.

- Advantages: Simple, widely used, and provides valuable data on material toughness.

- Applications: Suitable for assessing the impact resistance of blow bar.

- Izod Impact Test:

- Similar to the Charpy test but with a different sample orientation.

- Advantages: Effective for evaluating notch sensitivity and impact resistance.

- Applications: Useful for comparing the toughness of different blow bar materials.

| Method | Principle | Advantages | Applications |

|---|---|---|---|

| Charpy Impact Test | Energy absorbed during fracture | Simple, widely used, valuable data | Assessing impact resistance of blow bar |

| Izod Impact Test | Notch sensitivity and impact resistance | Effective for evaluating notch sensitivity | Comparing toughness of different materials |

3. Abrasion Testing

Abrasion testing evaluates the wear resistance of blow bar by subjecting them to abrasive conditions similar to their operational environment. This test is essential for predicting the lifespan and maintenance needs of blow bar.

Common Abrasion Testing Methods:

- Taber Abrasion Test:

- Measures the wear rate of a material when subjected to abrasive wheels.

- Advantages: Provides quantitative data on material wear resistance.

- Applications: Ideal for assessing the wear resistance of various blow bar materials.

- Dry Sand/Rubber Wheel Test:

- Measures the wear rate of a material when subjected to a rotating rubber wheel and abrasive sand.

- Advantages: Simulates real-world abrasive conditions and provides reliable data.

- Applications: Suitable for evaluating blow bar used in mining and quarrying applications.

| Method | Principle | Advantages | Applications |

|---|---|---|---|

| Taber Abrasion Test | Wear rate measurement with abrasive wheels | Quantitative data on wear resistance | Assessing wear resistance of blow bar |

| Dry Sand/Rubber Wheel Test | Wear rate measurement with sand and rubber wheel | Simulates real-world conditions, reliable data | Blow bar in mining and quarrying |

4. Fatigue Testing

Fatigue testing assesses the blow bar’s resistance to cyclic loading, which is essential for understanding how blow bar will perform under repetitive impact and stress conditions.

Common Fatigue Testing Methods:

- Rotating Bending Fatigue Test:

- Measures the number of cycles a material can withstand before failure under cyclic bending stress.

- Advantages: Provides valuable data on material endurance and lifespan.

- Applications: Suitable for evaluating blow bar subjected to repetitive stress.

- Axial Fatigue Test:

- Measures the number of cycles a material can endure under cyclic axial loading.

- Advantages: Effective for assessing the fatigue resistance of materials under real-world conditions.

- Applications: Ideal for blow bar experiencing cyclic loading in impact crushers.

| Method | Principle | Advantages | Applications |

|---|---|---|---|

| Rotating Bending Fatigue Test | Cyclic bending stress | Valuable data on endurance and lifespan | Evaluating blow bar under repetitive stress |

| Axial Fatigue Test | Cyclic axial loading | Effective for real-world conditions | Blow bar in impact crushers |

Advanced Techniques

In addition to traditional methods, advanced testing techniques have emerged to provide more detailed and accurate assessments of blow bar durability and performance.

1. Finite Element Analysis (FEA)

Finite Element Analysis is a computer-based simulation technique used to predict the behavior of blow bar under various loading conditions. FEA helps identify potential failure points and optimize blow bar design for enhanced performance.

Benefits of Finite Element Analysis:

- Predicts stress distribution and deformation.

- Identifies critical areas prone to failure.

- Optimizes blow bar design for improved durability.

Applications:

- Used during the design and development phase to create more durable and efficient blow bar.

2. Digital Image Correlation (DIC)

Digital Image Correlation is an optical method that measures deformation, displacement, and strain on the surface of blow bar. DIC provides high-resolution, full-field data that is crucial for understanding material behavior under operational conditions.

Benefits of Digital Image Correlation:

- Provides accurate and detailed measurements.

- Non-contact and non-destructive.

- Suitable for complex geometries and real-time monitoring.

Applications:

- Used for real-time monitoring of blow bar performance in laboratory and field settings.

| Advanced Technique | Principle | Benefits | Applications |

|---|---|---|---|

| Finite Element Analysis | Computer-based simulation | Predicts stress distribution, identifies failure points | Design and development of blow bar |

| Digital Image Correlation | Optical measurement of deformation and strain | Accurate, detailed measurements, non-destructive | Real-time monitoring of blow bar performance |

Conclusion

Innovative testing methods are essential for evaluating and enhancing the durability and performance of blow bar in impact crushers. Traditional techniques such as hardness testing, impact testing, abrasion testing, and fatigue testing provide valuable insights into material properties and behavior. Advanced methods like Finite Element Analysis and Digital Image Correlation offer detailed, real-time data that further optimize blow bar design and performance. By employing these testing methods, manufacturers and operators can ensure that blow bar meet the rigorous demands of quarry, mining, and industrial applications, ultimately leading to more efficient and reliable crushing operations.