In recent years, the sales of new energy vehicles in China have become higher and higher, with double-digit growth every year. The primary task of new energy vehicle manufacturing is to carry out lightweight design on the whole vehicle and reduce energy consumption. During the design process, the staff must strictly follow the actual situation of the vehicle and the corresponding national rules and regulations and guidelines to ensure the implementation of lightweight design of new energy vehicles and further improve the durability and safety of new energy vehicles.

At the same time, we should try to choose new and lighter materials to improve the overall performance of new energy vehicles, achieve the minimum standard of energy saving and energy consumption of new energy vehicles in China, and effectively promote the development of new energy vehicles in China. For this reason, all automobile companies are redesigning the structure of new energy vehicles, and also need to study and analyze the optimal structure, optimal assembly and optimal cost.

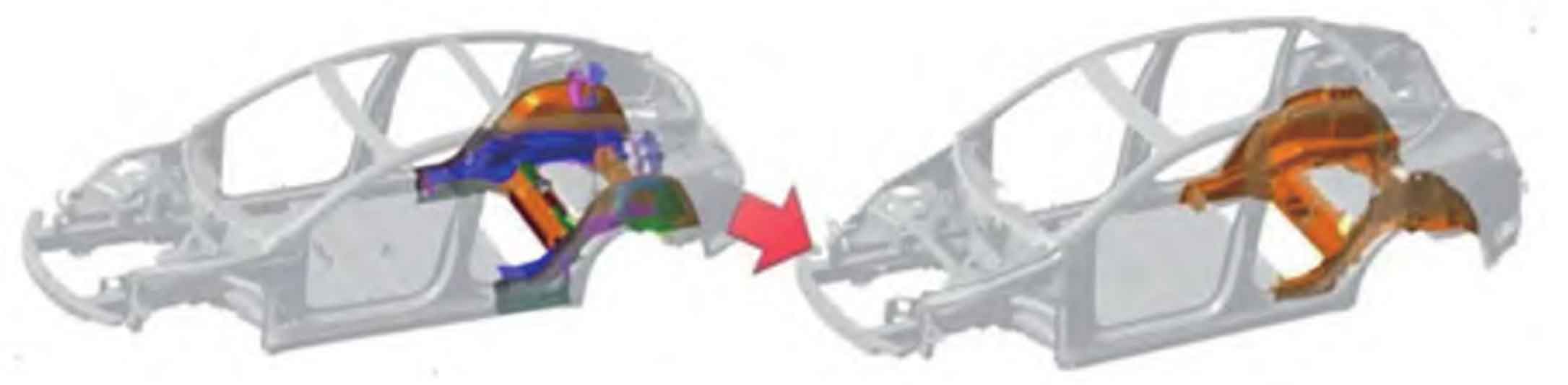

The automobile modular platform is conducive to cost saving, quality control and efficiency improvement, and is one of the core competencies of the future automobile enterprises. The chassis is not only the most important system in the vehicle platformization and modularization, but also the most obvious part of the flat and modularization characteristics of the vehicle parts because the chassis is closely related to the suspension, braking and other mechanisms. The same vehicle platform has highly standardized braking and suspension systems. Integrated casting can realize modular production.