In modern foundry engineering, the integration of computer simulation and optimization techniques has revolutionized the design and manufacturing of complex components, particularly for shell castings. As technology advances, simulation tools not only guide the initial process design but also enable intelligent optimization to balance quality and cost. Among these tools, Cast Designer stands out by embedding Design of Experiment (DOE) and Genetic Algorithm (GA) capabilities, allowing for systematic exploration and improvement of casting parameters. This article, from a first-person perspective, delves into the application of Cast Designer for the casting process design and optimization of shell castings, focusing on a case study involving a marine gas turbine steel shell casting. We will explore how DFM analysis, gating and risering system design, DOE, and GA-based optimization contribute to minimizing defects like shrinkage cavities while maximizing material yield, thereby achieving an optimal trade-off between quality and cost for shell castings.

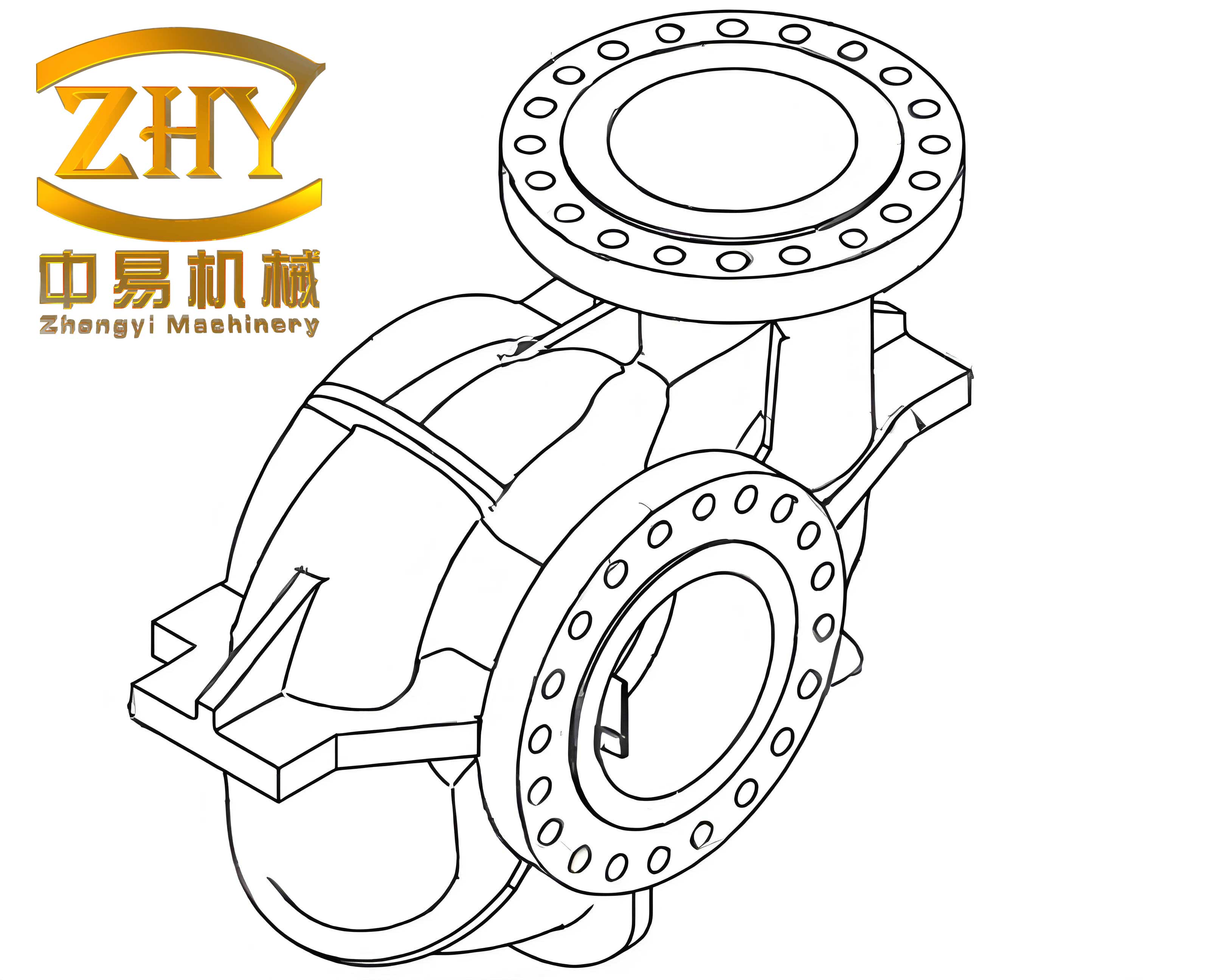

The shell castings in question are typically used in high-performance applications such as gas turbines, where structural integrity and precision are paramount. These shell castings often feature intricate geometries with varying wall thicknesses, ranging from 8 mm to 30 mm, and are composed of materials like ZG10Cr14Ni5Mo2, weighing around 104 kg. The complexity arises from non-uniform sections that predispose shell castings to thermal gradients and shrinkage defects during solidification. Traditional trial-and-error methods are time-consuming and costly, making simulation-driven approaches essential. Cast Designer provides a comprehensive environment for virtual prototyping, starting with Design for Manufacturability (DFM) analysis to assess castability before moving to detailed process optimization. In this work, we leverage Cast Designer to transform the process design for shell castings into a data-driven, intelligent endeavor, ensuring robust outcomes for industrial production.

DFM analysis in Cast Designer serves as the foundational step for evaluating the manufacturability of shell castings. It includes metrics such as Mass Distribution Index (MDI) and Heat Distribution Index (HDI), which predict potential issues like hot spots and shrinkage zones without requiring full simulation. For shell castings, HDI analysis is particularly valuable as it correlates well with solidification patterns, identifying regions with significant thickness variations that could lead to defects. In our case, the HDI map revealed pronounced thermal disparities in the upper and lower sections of the shell castings, indicating high risk for shrinkage cavities. This pre-emptive insight guided the initial riser placement, ensuring that feeding systems are strategically located to address these critical areas. Additionally, DFM tools assess draft angles, undercuts, and ejection forces, which are crucial for the moldability of complex shell castings. By integrating DFM early in the design phase, we can avoid costly redesigns and establish a solid baseline for subsequent optimization steps focused on shell castings quality.

Following DFM, the gating and risering system design for shell castings is optimized using Cast Designer’s automated wizards. The software calculates key parameters such as filling time, gate velocities, and runner dimensions based on the casting’s mass, geometry, and material properties. For shell castings, initial riser configurations—such as two top risers and two side risers—were evaluated through HDI, but results showed inadequate feeding in central and bottom regions. This prompted a redesign to one top riser and four side risers, improving thermal distribution and reducing shrinkage risks in shell castings. The gating system was similarly tuned to ensure smooth metal flow and minimize turbulence, which is critical for defect-free shell castings. The interplay between riser volume, placement, and gating design directly impacts both quality metrics (e.g., shrinkage volume) and economic factors (e.g., yield rate), setting the stage for DOE analysis to quantify these relationships for shell castings.

DOE analysis in Cast Designer enables a systematic investigation of how various process factors influence the quality of shell castings. We selected five key variables for shell castings: top riser size, side riser 1 size, side riser 2 size, chill application, and pouring temperature. Each factor was assigned multiple levels—for instance, riser sizes had small, medium, and large options, while chills had none, one, or two units. Pouring temperature ranged from 1540°C to 1580°C. A full factorial design resulted in 162 simulations, with output responses being shrinkage cavity volume (indicative of quality) and yield rate (indicative of cost). The DOE results for shell castings can be summarized in a relationship between yield rate and shrinkage volume, often expressed as:

$$ \text{Objective Function} = \min(\text{Shrinkage}) \quad \text{and} \quad \max(\text{Yield}) $$

where Yield Rate is defined as:

$$ \text{Yield Rate} = \frac{\text{Mass of Shell Castings}}{\text{Total Mass of Metal Poured}} \times 100\% $$

and Shrinkage Volume is a function of process parameters:

$$ V_s = f(R_t, R_{s1}, R_{s2}, C, T_p) $$

Here, \( V_s \) is shrinkage volume, \( R_t \) is top riser size, \( R_{s1} \) and \( R_{s2} \) are side riser sizes, \( C \) is chill design, and \( T_p \) is pouring temperature for shell castings. The DOE data revealed that side riser dimensions are the most influential factors, followed by top riser size, whereas chills and pouring temperature had lesser effects on shell castings. This insight is crucial for prioritizing adjustments in the optimization phase.

| Factor | Level 1 | Level 2 | Level 3 | Unit |

|---|---|---|---|---|

| Top Riser Size | Small | Medium | Large | Volume (mm³) |

| Side Riser 1 Size | Small | Medium | Large | Diameter (mm) |

| Side Riser 2 Size | Small | Medium | Large | Diameter (mm) |

| Chill Application | None | One Chill | Two Chills | Count |

| Pouring Temperature | 1540 | 1560 | 1580 | °C |

The DOE outcomes for shell castings are visualized in scatter plots showing yield rate versus shrinkage volume. Optimal points lie in the lower-right region, indicating high yield and low shrinkage. However, DOE alone may not capture the global optimum, as it relies on predefined levels. This limitation motivates the use of Genetic Algorithm (GA) for continuous optimization of shell castings parameters. GA mimics natural selection to iteratively improve solutions based on a fitness function that balances shrinkage and yield. For shell castings, we defined the fitness as:

$$ F = w_1 \cdot \text{Yield Rate} – w_2 \cdot \text{Shrinkage Volume} $$

where \( w_1 \) and \( w_2 \) are weights reflecting the importance of cost and quality, respectively. The GA operates on variables like top riser height, top riser angle, side riser diameter, and riser height-to-diameter ratio, exploring a broader design space than DOE. Through generations of selection, crossover, and mutation, GA converges to Pareto-optimal solutions for shell castings, represented as a curve where improving one objective worsens the other.

| Parameter | Start Value | End Value | Step Size | Unit |

|---|---|---|---|---|

| Top Riser Height | 120 | 160 | 10 | mm |

| Top Riser Angle | 60 | 64 | 2 | ° |

| Side Riser Diameter | 90 | 110 | 5 | mm |

| Riser H/D Ratio | 1.0 | 1.5 | 0.1 | Dimensionless |

The GA optimization for shell castings yielded a best compromise solution: a top riser height of 130 mm, angle of 62°, side riser diameter of 90 mm, and H/D ratio of 1.0. This configuration achieved a yield rate of 65.1% with a shrinkage volume of 254.64 mm³, demonstrating significant improvement over initial designs. The Pareto front from GA analysis clearly shows the trade-off between yield and shrinkage, enabling decision-makers to select a point aligned with production goals for shell castings. Moreover, the integration of DOE and GA in Cast Designer provides a robust framework for tackling multi-objective challenges in casting process design, especially for complex components like shell castings where small changes can have large impacts.

To further elucidate the relationships, we can model the shrinkage formation in shell castings using solidification principles. The shrinkage volume \( V_s \) often relates to thermal parameters such as modulus \( M \), which for a riser can be approximated as:

$$ M = \frac{V}{A} $$

where \( V \) is volume and \( A \) is surface area. For effective feeding in shell castings, risers must have a higher modulus than the casting sections they feed. The required riser volume \( V_r \) can be estimated from:

$$ V_r \geq \frac{V_c \cdot \alpha}{1 – \alpha} $$

with \( V_c \) being the casting volume and \( \alpha \) the shrinkage allowance (typically 3-6% for steel). In practice, simulation refines these estimates by accounting for three-dimensional heat transfer. For shell castings, the use of chills alters the cooling rate, modeled by Fourier’s law:

$$ q = -k \nabla T $$

where \( q \) is heat flux, \( k \) is thermal conductivity, and \( \nabla T \) is temperature gradient. By optimizing chill placement and riser design, we can manipulate \( \nabla T \) to reduce shrinkage in shell castings.

| Design Phase | Yield Rate (%) | Shrinkage Volume (mm³) | Key Parameters |

|---|---|---|---|

| Initial Design | ~50 | >300 | Two top risers, two side risers |

| DOE-Based Design | 58-63 | 260-290 | Adjusted riser sizes, chills varied |

| GA-Optimized Design | 65.1 | 254.64 | Top riser: 130 mm height, 62° angle; Side risers: 90 mm diameter |

The economic implications for shell castings are substantial. A higher yield rate reduces raw material costs, while minimized shrinkage enhances mechanical properties and reduces scrap. For shell castings produced in batches, even a 1% yield improvement can translate to significant savings. Additionally, the reduced defect rate lowers post-casting inspections and rework, streamlining the supply chain for shell castings. Cast Designer’s ability to simulate and optimize these factors virtually shortens development cycles and fosters innovation in designing shell castings for demanding applications.

Beyond the technical aspects, the adoption of Cast Designer for shell castings aligns with Industry 4.0 trends, where digital twins and AI-driven optimization become standard. The software’s user-friendly interface allows foundry engineers to iterate designs rapidly, testing scenarios that would be impractical physically. For shell castings with thin walls and complex cores, this is invaluable. Future enhancements could integrate real-time data from production sensors, creating a closed-loop system that continuously refines process parameters for shell castings based on actual outcomes.

In conclusion, the synergy of DFM, DOE, and GA in Cast Designer provides a powerful toolkit for optimizing the casting process of shell castings. By systematically analyzing factors like riser dimensions, chills, and pouring temperature, we achieve an optimal balance between quality (low shrinkage) and cost (high yield). The case study demonstrates that for shell castings, side riser sizes are critical, and GA can uncover superior designs beyond manual intuition. This methodology not only improves the manufacturability of shell castings but also sets a precedent for data-driven foundry practices. As simulation technology evolves, its role in crafting reliable, efficient shell castings will only grow, driving advancements in sectors like aerospace, marine, and energy where shell castings are pivotal components.

The journey from design to optimized production for shell castings underscores the importance of virtual tools in modern manufacturing. With Cast Designer, we can preempt defects, conserve materials, and accelerate time-to-market for shell castings. This holistic approach, combining simulation with intelligent algorithms, ensures that shell castings meet stringent performance criteria while remaining economically viable. As we continue to refine these techniques, the future of shell castings manufacturing looks increasingly precise, sustainable, and innovative.