Shrinkage defects are a common concern in metal casting processes that can negatively impact the quality and integrity of cast components. These defects occur due to the volumetric contraction that takes place during solidification. While process parameters and material properties play significant roles in shrinkage control, the casting design itself can also influence the occurrence and severity of shrinkage defects. Understanding the relationship between casting design and shrinkage defects is crucial for optimizing the design process and minimizing the occurrence of defects. In this article, we delve into the factors related to casting design that can affect shrinkage defects.

- Casting Section Thickness: The section thickness of a casting has a direct influence on the solidification rate and subsequent shrinkage. Thick sections solidify more slowly, leading to a higher risk of shrinkage defects. Designers should consider the appropriate thickness for each section of the casting to ensure uniform solidification and minimize the potential for shrinkage defects.

- Geometry and Complexity: The complexity of a casting’s geometry can affect the solidification pattern and create regions prone to shrinkage defects. Sharp corners, thin projections, and intricate features can impede the proper flow of molten metal and result in localized solidification and subsequent shrinkage defects. Designers should aim for smooth and gradual transitions in the geometry to promote uniform cooling and solidification.

- Feeding and Riser Design: Adequate feeding and riser design are critical for compensating for solidification shrinkage. The design should incorporate properly sized and positioned risers to act as reservoirs, supplying molten metal to the solidifying casting and compensating for volumetric contraction. Insufficient or improperly designed feeders and risers can lead to inadequate feeding and increased shrinkage defects.

- Mold Design and Venting: The mold design and venting system play crucial roles in the solidification and cooling of the casting. Proper mold design should consider factors such as mold material, mold surface finish, and the arrangement of vents and gates. Effective venting allows the escape of gases generated during solidification, preventing the formation of voids and promoting sound castings.

- Material Selection: The selection of casting materials can impact the shrinkage behavior. Some materials have wider solidification temperature ranges, increasing the likelihood of shrinkage defects. Designers should carefully consider material properties, including solidification characteristics, to select alloys that minimize shrinkage defects and promote sound castings.

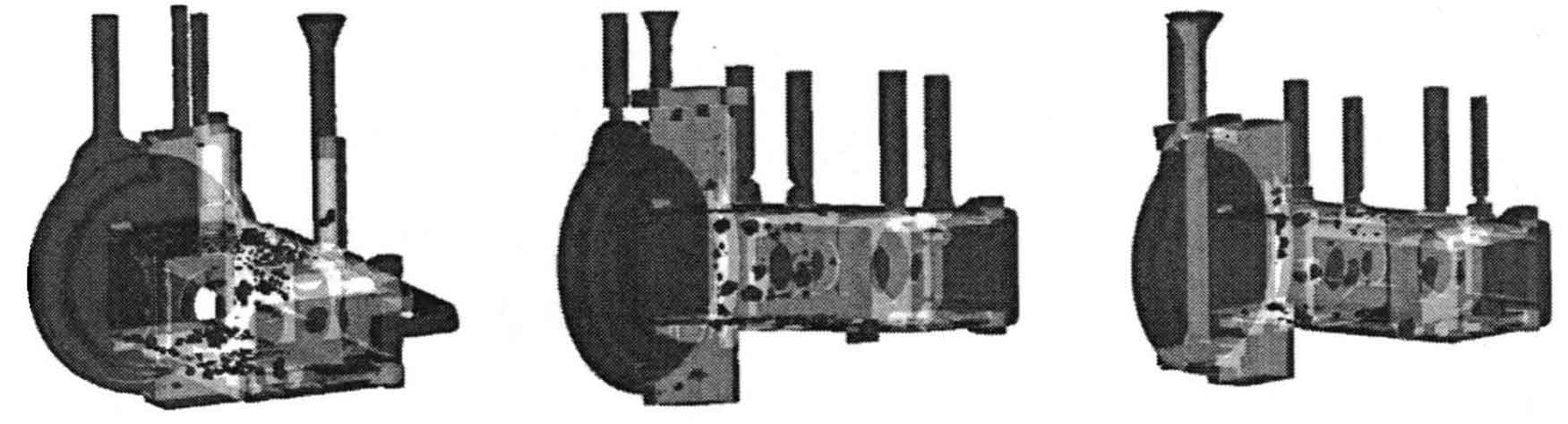

- Simulation and Analysis: Utilizing casting simulation software can provide valuable insights into the solidification and shrinkage behavior of castings. By simulating the casting process, designers can identify potential areas of concern and optimize the design parameters to minimize shrinkage defects. Simulation allows for virtual testing of different design iterations, leading to improved casting designs that reduce the occurrence of shrinkage defects.

Investigating the relationship between casting design and shrinkage defects is essential for achieving high-quality castings. By considering factors such as section thickness, geometry, feeding and riser design, mold design, material selection, and utilizing advanced simulation tools, designers can optimize the casting design to minimize shrinkage defects. Collaboration between design engineers, foundry personnel, and casting simulation experts is crucial for effectively addressing shrinkage concerns and ensuring the production of defect-free castings.