Abstract:

The numerical simulation and optimization of the investment casting process for a bypass valve casting using MAGMA software. By analyzing the flow of molten metal into the mold cavity, potential defects such as porosity and cold shuts caused by air entrainment and discontinuous liquid flow were predicted. Based on these predictions, the gating cup position was reoptimized, and the filling and solidification processes of the optimized process were simulated to predict potential shrinkage and porosity risks. The simulation results were verified through actual trial production, and the castings were found to be defect-free, satisfying technical requirements. This study demonstrates the effectiveness of numerical simulation in guiding the design and optimization of investment casting processes for complex castings.

1. Introduction

Investment casting, also known as lost-wax casting, is an advanced near-net-shape manufacturing technology capable of producing small metal castings with complex internal cavity structures, high melting temperatures, high dimensional accuracy, minimal machining requirements, and low surface roughness. It is widely used in aerospace, automotive, marine, and other fields. However, the process is complex, has a long production cycle, and is challenging to control, traditionally relying heavily on trial and error. With the development of modern industry, castings are becoming larger in size, more complex in structure, and thinner in section, making the prediction and suppression of filling and solidification defects a difficult challenge in investment casting technology. The rapid development of numerical simulation technology has provided a new means for studying the filling and solidification processes of castings and is now widely used to guide production practice.

2. Methodology

2.1. Casting Description

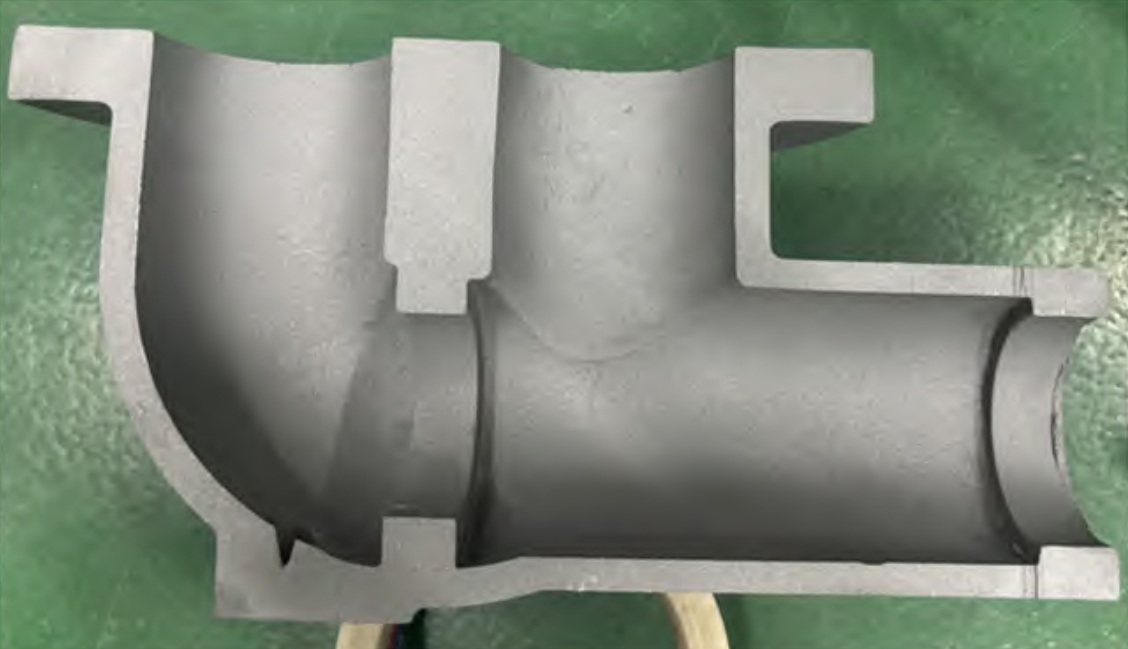

The bypass valve casting has dimensions of 120mm × 132mm × 253mm, with a wall thickness ranging from 10 to 25mm and an internal cavity diameter of φ51 to φ60mm. The casting material is 20Mn5M, with a mass of 6.7kg. The casting is required to be free of shrinkage porosity, slag inclusion, cracks, and other defects.

2.2. Numerical Simulation Using MAGMA

The three-dimensional modeling of the investment casting process for the bypass valve was performed using UG software. The numerical simulation was conducted using MAGMA software with the following parameters: a total mesh number of 5×102·K), pouring temperature of 1560°C, pouring speed of 3kg/s, and air cooling as the cooling method.

3. Results and Discussion

3.1. Filling Simulation

The filling simulation results for the original investment casting process. It can be seen that the molten metal enters the mold cavity mainly through gates 1#, 2#, and 4#, with only a small amount of molten metal entering through gate 3# in a discontinuous manner, which can easily cause cold shut defects.

To address the issue of turbulent flow, the gating cup position was reoptimized, placing it directly above gate 2# on the cross runner. The optimized filling simulation results. The molten metal enters the mold cavity smoothly through gate 2# without entering through other gates, resulting in a more stable filling process.

3.2. Solidification Simulation and Defect Analysis

It can be seen that there are no isolated liquid phases during the solidification process, indicating that the casting process achieves sequential solidification.

Larger shrinkage porosity defects appear in the gating cup and runner. Smaller shrinkage porosity defects appear in area G of the casting, which can be eliminated by wrapping the runner and gates with insulation cotton to enhance feeding.

4. Trial Production and Verification

Based on the optimized investment casting process, trial production was conducted. After removing the pouring system, the castings were cleaned, sanded, and visually inspected. The castings had a good appearance with no cracks, shrinkage porosity, sand holes, or other defects. The surface roughness of the castings was ≤6.3μm, satisfying the technical requirement of no more than 12.5μm.

X-ray inspection and dissection were performed on the first batch of castings. The X-ray inspection results showed no internal defects such as shrinkage porosity, slag inclusion, or cracks. The dissection results also confirmed the absence of visible defects.

5. Conclusion

This study demonstrated the effectiveness of numerical simulation using MAGMA software in guiding the design and optimization of the investment casting process for bypass valve castings. By analyzing the filling and solidification processes, potential defects were predicted and addressed through process optimization. The optimized process resulted in castings with good appearance, surface roughness, and mechanical properties, satisfying technical requirements. The study highlights the importance of numerical simulation in improving the efficiency and quality of investment casting processes for complex castings.

Table 1: Key Parameters of the Investment Casting Process

| Parameter | Value |

|---|---|

| Casting Material | 20Mn5M |

| Mold Material | Zircon Sand |

| Mold Temperature | 950°C |

| Heat Transfer Coef. | 500W/(m^2·K) |

| Pouring Temperature | 1560°C |

| Pouring Speed | 3kg/s |

| Cooling Method | Air Cooling |

| Gating Cup Position | Above Gate 2# |

Table 2: Defect Prediction and Mitigation Measures

| Defect Type | Predicted Location | Mitigation Measure |

|---|---|---|

| Cold Shut | Gate 3# | Optimize gating cup position |

| Shrinkage Porosity | Runner, Gates, Area G | Wrap runner and gates with insulation cotton |

In conclusion, the numerical simulation using MAGMA software played a crucial role in predicting and mitigating potential defects in the investment casting process of the bypass valve casting. The optimized process resulted in high-quality castings that satisfied technical requirements, demonstrating the effectiveness of numerical simulation in guiding the design and optimization of investment casting processes.