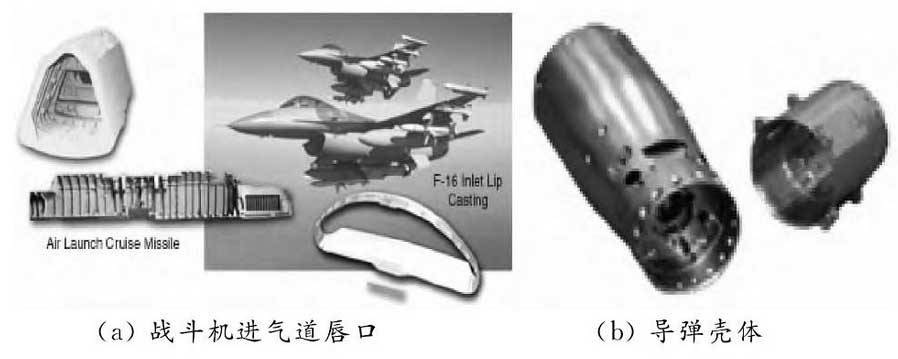

Aluminum alloy castings are widely used in advanced weapons because of their low density, high specific strength, good corrosion resistance, easy forming and low cost. Aluminum alloy precision casting technology refers to the casting of large, thin-walled, complex, integral and high-performance aluminum alloy components without or with little allowance. The outline size is generally 1500 mm, and the wall thickness is about 3 mm. The casting performance basically reaches the performance index of medium deformation alloy, which is no or with little machining allowance [7]. Developed countries such as Europe and the United States have widely used integrated precision casting technology to develop various kinds of large-scale thin-walled integrated aluminum alloy precision castings [8], which are used in advanced combat aircraft and airframe, missile engine and missile body, high motor armored vehicle engine and other key parts, and replace some aluminum alloy forgings and sheet metal parts [9, 10]. For example, the complex thin-walled integral gearbox and shell of the Black Hawk helicopter engine; the inlet lip of the F-16 fighter (see Figure 2a); and the advanced missile shells such as the U.S. Tomahawk cruise missile and BAT missile are also made of aluminum alloy integral precision castings (see Figure 2b).

In recent years, with the rapid development of numerical simulation technology, the computer-aided design and process optimization of thin-walled complex integral aluminum alloy precision casting have been realized, the process design level has been improved, and the product development cycle has been shortened.