Abstract:

This article discusses the comprehensive design and manufacturing process of a large steel casting pump cover for marine dredging pumps. The pump cover, made of ZG270-500 cast steel, is a critical component of the dredging system, requiring strict quality control to avoid casting defects such as shrinkage porosity and shrinkage cavities. The article outlines the casting process design, including mold making, pouring system configuration, riser placement, and subsidization strategies. Additionally, it discusses the use of CASTsoft simulation software to predict and prevent casting defects. Practical insights gained from the production process are shared, emphasizing the importance of careful process planning and quality assurance measures for large steel castings.

Introduction

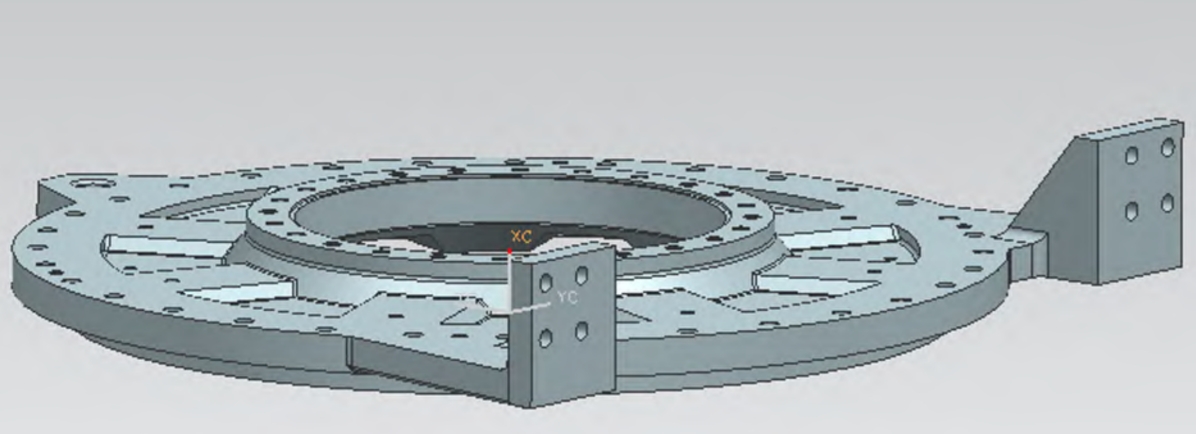

The pump cover is a vital component of marine dredging pumps, responsible for directing fluid flow within the pump assembly. As a large and complex casting, it must meet stringent quality standards to ensure reliable operation under demanding conditions. This article presents the design, manufacturing, and quality control aspects of producing a ZG270-500 steel casting pump cover for a marine dredging pump.

1. Product Requirements and Casting Challenges

1.1 Pump Cover Structure and Material Specification

The pump cover is a plate-like casting with a maximum diameter of approximately 2600 mm and a height of nearly 260 mm (excluding the feet). Key mating surfaces require a high degree of quality, with no shrinkage porosity, shrinkage cavities, or inclusions. The material specification for the pump cover is ZG270-500 cast steel, with the chemical composition and mechanical properties outlined in Tables 1 and 2, respectively.

Table 1: Chemical Composition of ZG270-500 Cast Steel

| Element | C | Si | Mn | Ni | Cr | Mo | P | S |

|---|---|---|---|---|---|---|---|---|

| Range | 0.30-0.35 | 0.15-0.20 | 0.35-0.40 | 0.60-0.90 | ≤0.30 | ≤0.20 | ≤0.04 | ≤0.04 |

Table 2: Mechanical Properties of ZG270-500 Cast Steel

| Property | Specification |

|---|---|

| Tensile Strength, R<sub>m</sub> (MPa) | ≥500 |

| Yield Strength, R<sub>p</sub> (MPa) | 270 |

| Elongation, A (%) | ≥18 |

| Impact Absorption Energy, A<sub>kv</sub> (J) | ≥27 |

| Brinell Hardness, HBW | 217-255 |

1.2 Casting Challenges

The pump cover presents several casting challenges due to its size, shape, and material properties:

- Uneven Wall Thickness: The pump cover has varying wall thicknesses, with the thickest section measuring 180 mm and the thinnest at 80 mm.

- Dispersed Hot Spots: Multiple hot spots require effective feeding to prevent shrinkage defects.

- Complex Geometry: The intricate shape and large size complicate the mold-making and pouring processes.

- Material Properties: ZG270-500 cast steel has high strength and moderate ductility, necessitating careful control during casting to avoid cracking or other defects.

2. Casting Process Design

To address the casting challenges, a comprehensive process design was developed, incorporating several key strategies.

2.1 Mold Design and Preparation

The mold was designed using resin sand with a false box molding technique, suitable for mass production of large castings requiring core removal. The following steps were taken to ensure mold quality:

- Sand Mixing and Compaction: High-quality resin sand was mixed and compacted to ensure uniform density and strength.

- Coating Application: A high-quality coating was applied to prevent gas porosity and adhere to the mold surface.

- Ventilation Channels: Proper ventilation channels were incorporated to facilitate gas escape during pouring.

2.2 Pouring System Configuration

The pouring system was designed to ensure smooth and rapid filling of the mold cavity while minimizing turbulence and oxidation. A bottom-pour gating system was selected due to its ability to promote stable metal flow and reduce the risk of turbulence and air entrapment.

Table 3: Pouring System Dimensions

| Component | Dimension (mm) |

|---|---|

| Sprue | φ110 |

| Runner | 100×120 |

| Ingate | 15×60 (10 inlets per side) |

2.3 Riser Design and Placement

Effective feeding was crucial to prevent shrinkage defects. Risers were strategically placed at hot spots identified through solidification simulations. A combination of elliptical heating risers and conventional risers was used to provide ample feeding material.

Table 4: Riser Dimensions

| Riser | Dimensions (mm) | Material |

|---|---|---|

| Riser 1 | 200x300x500 | Elliptical heating |

| Riser 2 | 160x240x350 | Conventional |

2.4 Subsidization

To ensure adequate feeding to distant hot spots, subsidization was employed by adding extra material beneath the risers. This ensured a continuous feeding channel during solidification.

3. Simulation-Aided Process Optimization

CASTsoft simulation software was used to predict solidification behavior and identify potential defects. The software provided valuable insights into metal flow patterns, temperature distributions, and the formation of shrinkage porosity and cavities.

The simulation revealed the need for additional subsidies and risers in specific regions to prevent shrinkage defects. Adjustments were made based on the simulation results, and the process was refined accordingly.

4. Casting Execution and Quality Control

The optimized casting process was executed, with strict quality control measures in place throughout.

4.1 Pouring and Solidification

The molten steel was poured at a controlled temperature to ensure consistent filling of the mold. The pouring rate was adjusted to minimize turbulence and promote stable solidification.

4.2 Defect Inspection

Upon cooling, the castings were inspected for defects such as shrinkage porosity, shrinkage cavities, and cracks. Non-destructive testing methods like ultrasonic inspection and magnetic particle inspection were used to detect internal and surface defects.

Table 5: Defect Inspection Methods

| Inspection Method | Purpose |

|---|---|

| Visual Inspection | Surface cracks, porosity, inclusions |

| Ultrasonic Inspection | Internal defects, porosity, cracks |

| Magnetic Particle Inspection | Surface cracks, defects near surface |

4.3 Heat Treatment

The castings underwent heat treatment to improve mechanical properties and relieve residual stresses. The heat treatment cycle included austenitizing, quenching, and tempering, as per the material specification.

5. Results and Discussion

The final pump covers met all specified requirements, with no detectable defects and excellent mechanical properties. The optimized casting process resulted in a significantly reduced defect rate and improved process efficiency.

Table 6: Mechanical Properties of the Final Pump Covers

| Property | Measured Value | Specification |

|---|---|---|

| Tensile Strength, R<sub>m</sub> (MPa) | 620 | ≥500 |

| Yield Strength, R<sub>p</sub> (MPa) | 320 | 270 |

| Elongation, A (%) | 19.4% | ≥18% |

| Impact Absorption Energy, A<sub>kv</sub> (J) | 28 | ≥27 |

| Brinell Hardness, HBW | 235 | 217-255 |

The success of the project underscores the importance of comprehensive process planning, simulation-aided optimization, and rigorous quality control measures in the production of large steel castings.

6. Conclusion

The development and production of the ZG270-500 steel casting pump cover for marine dredging pumps required a meticulous approach to casting process design and execution. The integration of simulation software, strategic riser placement, and subsidization strategies enabled the production of defect-free castings with excellent mechanical properties. This project highlights the critical role of advanced simulation tools and rigorous quality control in ensuring the success of large steel casting projects.

References

- Zeng, M. (2010). Application of Tilt Pouring Process in Steel Casting Production. Casting Technology, 10, 1372-1373.

- Zhao, Y. (2008). Design Principles of Gating System for Large Steel Castings. Casting Technology, 10, 1425-1426.

- China Machinery Engineering Society, Casting Professional Society. (2011). Casting Handbook: Volume 5 – Casting Process (3rd ed.). Beijing: China Machine Press.

- Liu, X., & Liang, H. (2009). Casting Defect Prediction Based on CASTsoft_CAE Software. Mechanical Engineering, 4, 60-63.

- Wang, Y., & Jin, S. (2007). Metallic Materials and Heat Treatment. Beijing: China Machine Press.