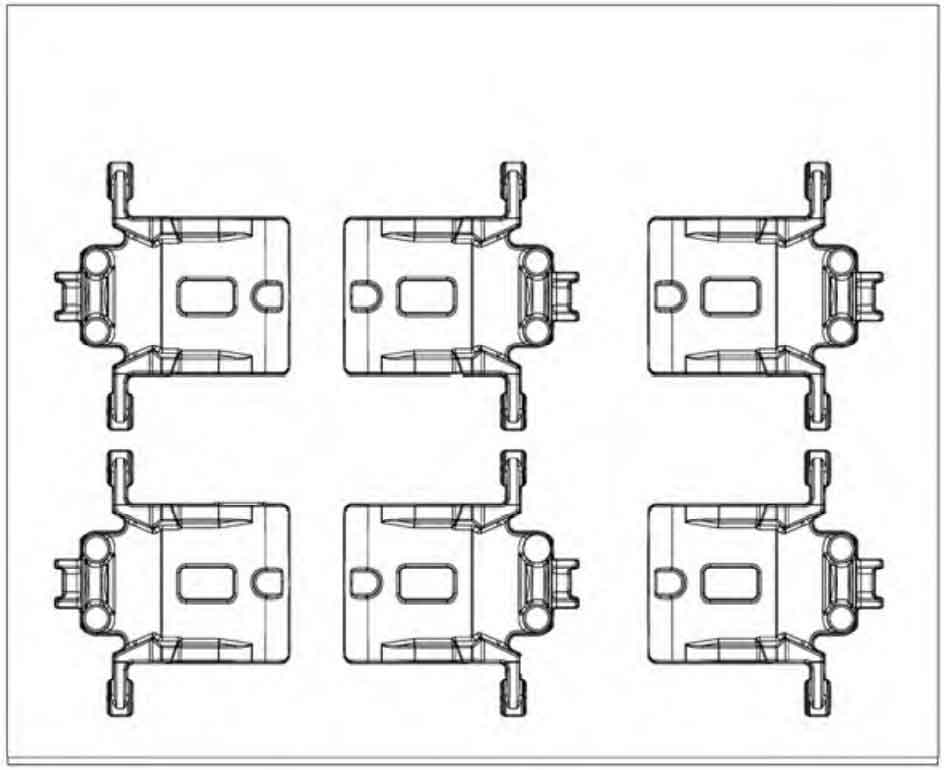

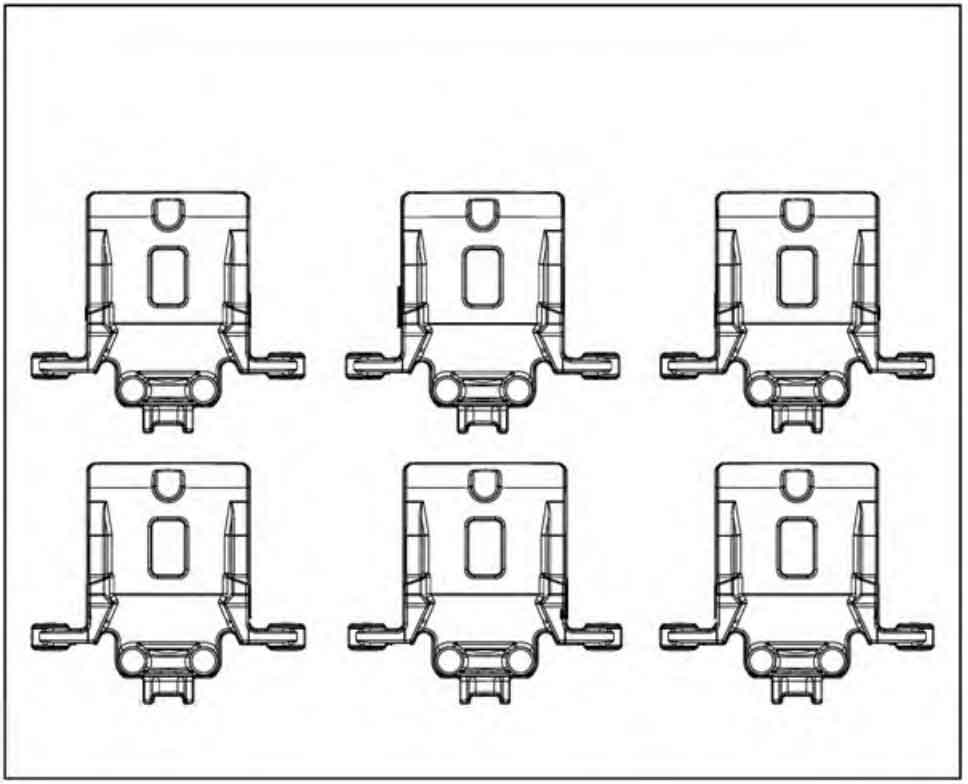

The DISA230B vertical parting boxless injection molding machine is used, and the size of the molding plate is 650 mm × 535 mm。 According to the conventional process layout (vertical placement of cylinder barrel), if 6 ductile iron castings are placed, the gating system cannot be placed on both sides, and the sand intake is insufficient, as shown in Figure 1, so only 4 ductile iron castings can be placed on each type, as shown in Figure 2.

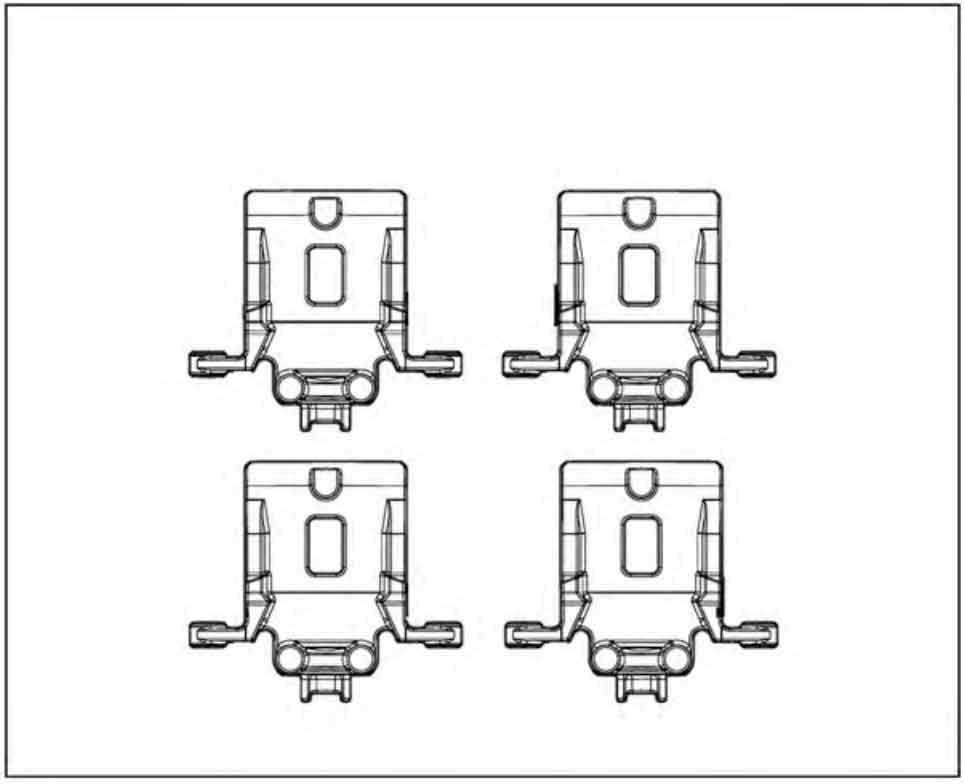

If the cylinder barrel is horizontally placed, the horizontal space of the molding plate can be saved, so three ductile iron castings can be placed in the horizontal direction, and two ductile iron castings can be placed in the vertical direction, that is, six ductile iron castings. As shown in Figure 3, the process yield reaches 61.6%, which is 19% higher than the conventional process.

By adjusting the distribution of the distance between ductile iron castings, the process layout shown in Figure 3 is adopted. Among them, 4 pieces are placed in the same direction, and the remaining 2 pieces are placed in the opposite direction, which is conducive to placing the riser and arranging the gating system.