Low pressure die casting makes the metal liquid fill in the anti gravity direction by controlling the gas flow. It has the characteristics of controllable filling, continuous fluid, good mechanical properties, complex forming castings and low cost. It has been widely used in the production of automobile cylinder block. Production of cylinder block by low pressure die casting technology at home and abroad.

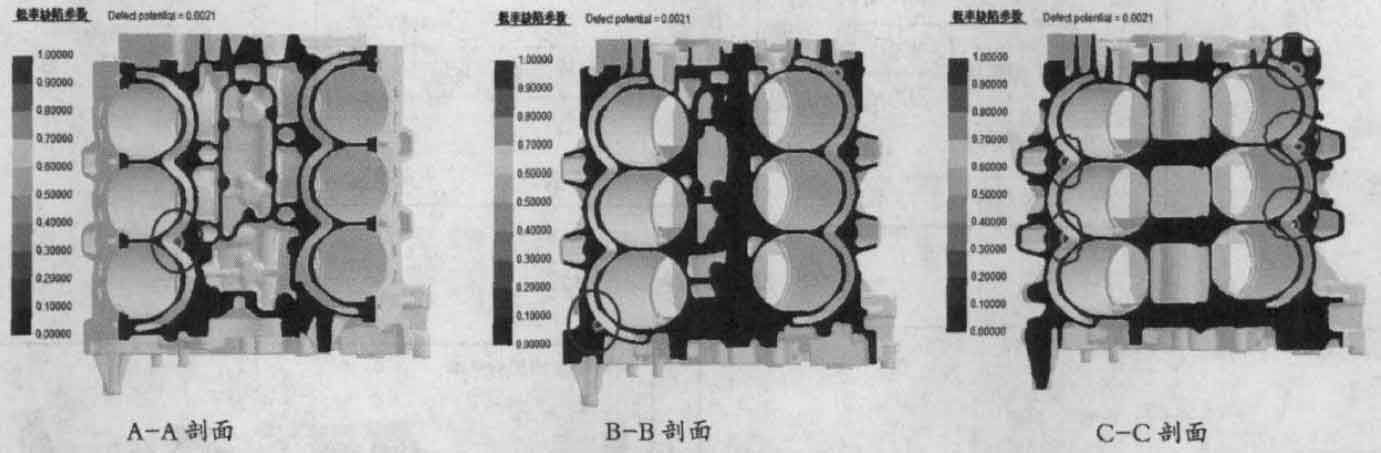

He Haitao carried out numerical simulation and process optimization of low pressure die casting process of V-type aluminum alloy cylinder block. Before the process optimization, the bolt hole of V-shaped aluminum alloy cylinder block is easy to produce shrinkage cavity and porosity defects, which is similar to the actual casting production. The defect simulation results are shown in Figure 1. After process optimization, the shrinkage porosity defect at this part of the casting can be eliminated, as shown in Figure 2.

Shang Guifan and others studied the water-cooling process of low-pressure die casting of the lower cylinder block of the engine. Without changing the structural form of other parts of the mold, they added copper plates in the upper mold and set cooling pipes in the copper plates, as shown in Figure 3. Effectively shorten the holding time and cooling time in the casting process, and improve the production efficiency.

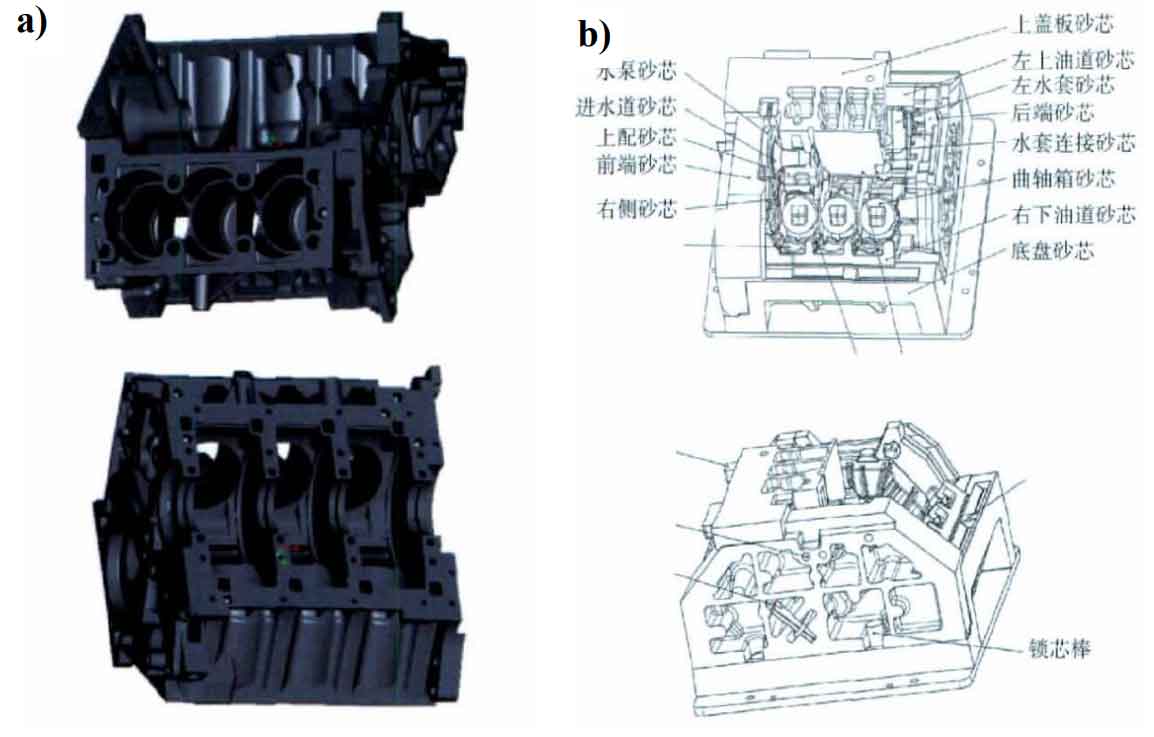

Liu Yongyue and others studied the low pressure die casting process of Al alloy cylinder block assembly core of V6 engine. As shown in Figure 4, by adopting the low-pressure die casting process, the process yield is more than 90% and the yield is 95%.