In order to further study the impact toughness of nodular cast iron for wind power fittings, the impact fracture of B2 and B4 attached cast samples in the later stage of the experiment was analyzed by SEM. The fracture process of nodular cast iron includes the formation and propagation of fracture cracks. By observing the macro and micro characteristics of fracture, we can understand the formation and propagation process of cracks, and analyze the reasons for the different impact toughness of nodular cast iron.

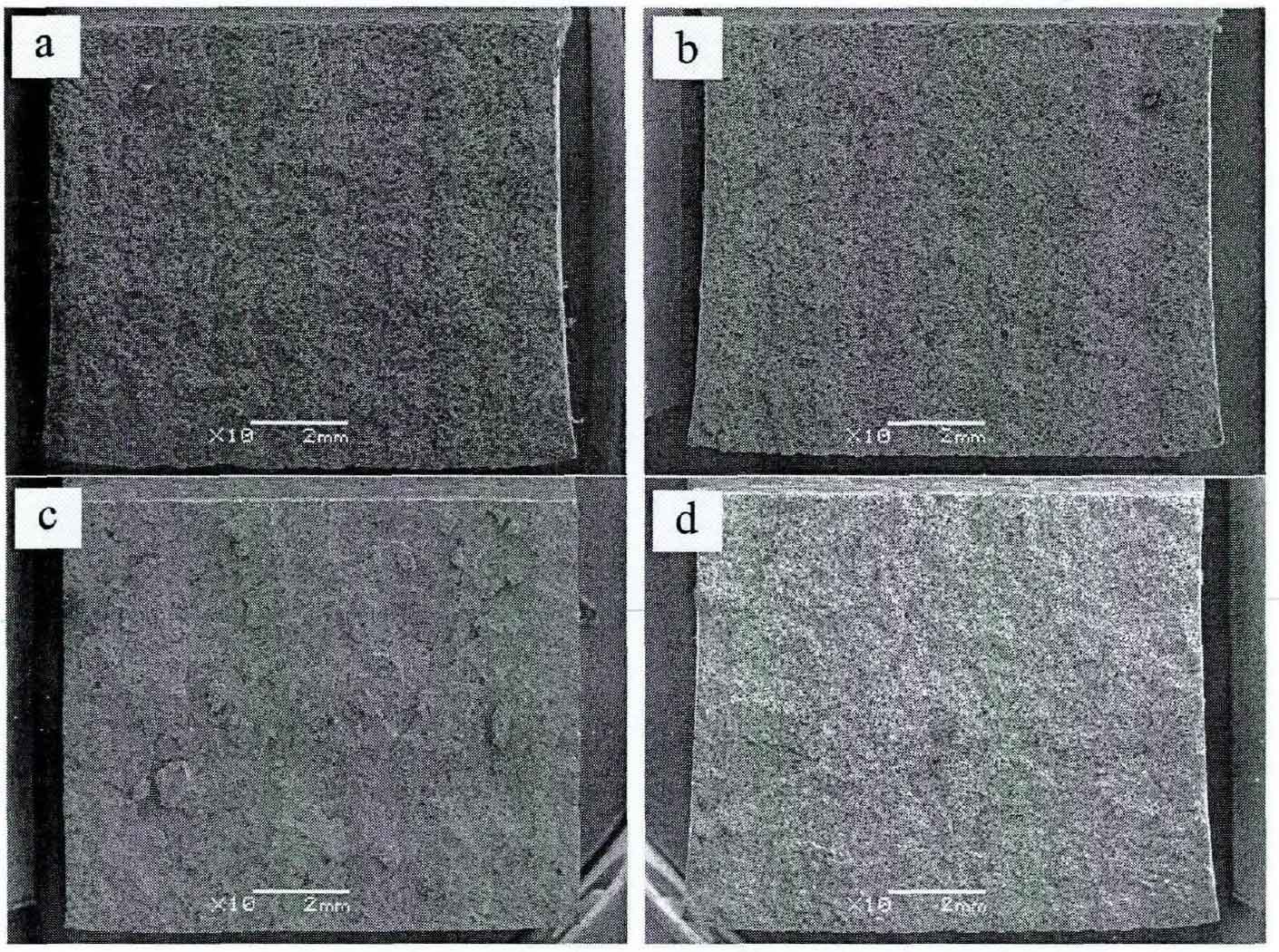

The macro morphology of each impact fracture is scanned, and the scanning photos are shown in the figure. By observing figures a and B, it is found that the macro morphology of the section of B2 in the as cast and heat-treated States is very similar, the microstructure of the whole section is uniform and dense, there is slight plastic deformation around, and the color is dark gray. There is no obvious division on the section, the morphology is similar to the fiber area of the ductile fracture, no obvious radiation area and shear lip area are found, and a large number of black dots are evenly distributed on the section. By observing figures C and D, it is found that the macro morphology of the fracture and the analysis of the macro morphology of the fracture under as cast and heat treatment are obviously different. Under the as cast condition, the surface of the section is smooth, there is no deformation around, the color is dark gray, there is no zoning phenomenon, and there are no densely distributed black dots. After heat treatment, the section structure is similar to B2, with slight plastic deformation around, silvery white color, and a large number of black dots appear on the section. It can be seen that the fracture belongs to brittle fracture in the macro morphology and analysis of fracture.