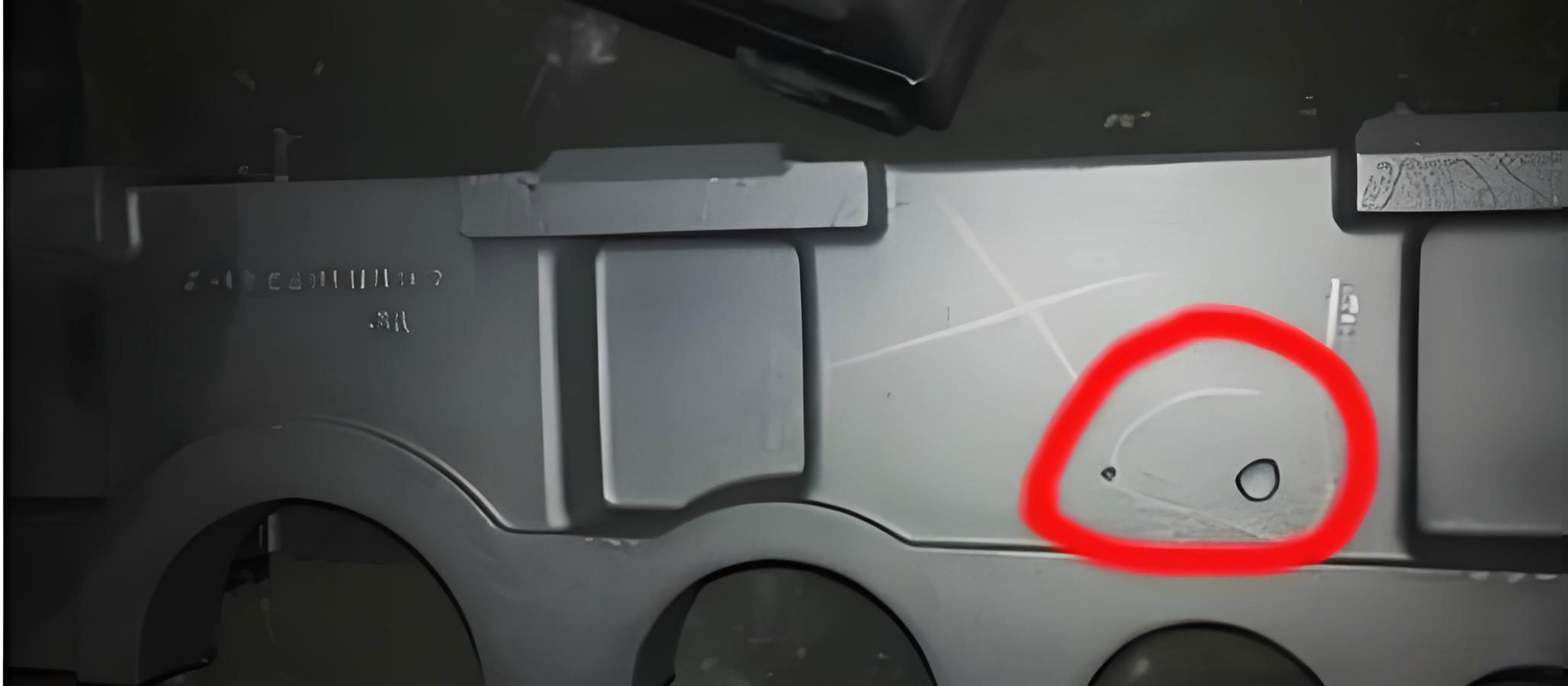

In my extensive experience spanning over fourteen years in staff training and technical management within steel foundries, I have repeatedly confronted the pervasive and costly issue of porosity in casting. This defect, manifesting as cavities or blowholes within solidified metal, severely compromises the mechanical integrity, pressure tightness, and surface quality of cast components. The financial losses from scrap and rework are substantial, not to mention the damage to customer trust. One particularly stark instance involved the production of heavy-duty hinge girders, where a batch suffered from severe porosity in casting, leading to the rejection of sixteen pieces and significant monetary loss. Expert analysis pointed unequivocally to deficiencies in the steelmaking process itself. This catalyzed the formation of a dedicated quality task force, which I led, with the singular objective of eradicating porosity in casting by fundamentally improving molten steel quality through rigorous process control.

The core premise of our approach was that porosity in casting, especially of the subcutaneous and macroscopic types often observed, is predominantly a function of gas content—primarily hydrogen and nitrogen—and non-metallic inclusions in the liquid steel before pouring. During solidification, the solubility of these gases drops dramatically, causing them to nucleate and form bubbles trapped within the casting structure. Therefore, the battle against porosity in casting is won or lost during the electric arc furnace (EAF) melting and refining stages. Our initial step was a forensic, data-driven audit of past practices. We analyzed the complete melting logs for 38 heats previously used for the problematic hinge girders. The data was segmented into the three canonical phases of EAF steelmaking: melting, oxidation, and reduction. The findings, summarized below, revealed systemic inconsistencies directly linked to the occurrence of porosity in casting.

The melting period sets the stage for all subsequent refining. Its primary objectives are efficient melt-down and establishing an initial carbon content that enables effective oxidation. The carbon balance is governed by:

$$ C_{\text{charge}} = C_{\text{final}} + \Delta C_{\text{melting loss}} + \Delta C_{\text{oxidation}} $$

where \( C_{\text{charge}} \) is the charged carbon, \( C_{\text{final}} \) is the aim carbon before tap, \( \Delta C_{\text{melting loss}} \) is carbon lost during melt-down via oxidation, and \( \Delta C_{\text{oxidation}} \) is the intentional decarburization amount. Our audit showed a critical failure in this phase.

| Parameter | Condition | Number of Heats | Percentage (%) | Implication for Porosity in Casting |

|---|---|---|---|---|

| Carbon at Melt-out | Low (C < 0.45%) | 19 | 50.0 | Insufficient carbon for subsequent boiling reaction, limiting gas removal and increasing risk of porosity in casting. |

| Optimal (C = 0.45-0.65%) | 11 | 28.95 | ||

| High (C > 0.65%) | 8 | 21.05 | ||

| Primary Cause | Incorrect charge carbon calculation and/or improper oxygen lancing practice during melt-down. | |||

The oxidation period is the heart of purification. The controlled oxidation of carbon creates a violent “carbon boil”:

$$ [C] + (FeO) \rightarrow CO_{(g)} \uparrow + [Fe] $$

This evolving carbon monoxide gas stirs the bath, homogenizes temperature and composition, and most crucially, flushes out dissolved gases like hydrogen \([H]\) and nitrogen \([N]\), as well as non-metallic inclusions. The efficacy of this degassing is proportional to the volume of CO generated, which depends on the decarburization amount (\(\Delta C\)) and rate. The theoretical removal of hydrogen can be modeled by:

$$ \frac{d[H]}{dt} = -k \cdot A \cdot ([H] – [H]_{eq}) $$

where \(k\) is a mass transfer coefficient, \(A\) is the bubble interfacial area, and \([H]_{eq}\) is the equilibrium concentration with the CO bubble (near zero). A larger \(\Delta C\) creates more bubbles (increasing \(A\)) and longer agitation, enhancing degassing. Our historical data exposed major shortcomings.

| Deficiency | Metric | Heats | Percentage (%) | Consequence for Porosity in Casting |

|---|---|---|---|---|

| Insufficient Decarburization | \(\Delta C \leq 0.30\%\) | 19 | 50.0 | Inadequate gas purge, leaving high residual gas content destined to cause porosity in casting. |

| Poor End-point Carbon Control | C < 0.15% | 24 | 63.16 | Uncontrolled finish leads to over-oxidation or excessive FeO, complicating reduction and promoting re-oxidation, a source of porosity in casting. |

| C = 0.18-0.25% | 10 | 26.32 | ||

| C > 0.25% | 4 | 10.53 | ||

| Procedural Lapse | No final oxygen sample taken | 19 | 50.0 | Lack of data for informed transition to reduction, leading to guesswork and variability. |

| Temperature Excursion | Temperature > 1590°C | 30 | 78.95 | Excessive temperature increases gas solubility and refractor wear, risking later gas evolution and porosity in casting. |

The reduction (or refining) period aims to deoxidize and desulfurize the steel under a protective slag. Effective diffusion deoxygenation under a white slag is critical to prevent the formation of CO bubbles during solidification, another key mechanism for porosity in casting. The deoxidation reaction follows:

$$ [O] + (C) \rightarrow CO_{(g)} \quad \text{(undesired in mold)} $$

$$ [O] + (Si, Al, etc.) \rightarrow (SiO_2, Al_2O_3) \quad \text{(desired in ladle/furnace)} $$

A white slag, rich in CaO and with low FeO, facilitates oxygen diffusion from metal to slag. The kinetics are governed by Fick’s law, requiring sufficient time. Our audit revealed critical gaps here as well.

| Parameter | Condition | Heats | Percentage (%) | Impact on Porosity in Casting |

|---|---|---|---|---|

| Final Carbon Control | Low (C < 0.27%) | 8 | 21.0 | Requires risky late carbon addition (e.g., electrode immersion), which can introduce gases and cause localized boiling, seeding porosity in casting. |

| Optimal (C = 0.27-0.35%) | 20 | 52.7 | ||

| High (C > 0.35%) | 10 | 26.3 | ||

| White Slag Time | Insufficient (< 20 min) | 15 | 39.5 | Incomplete deoxidation, leaving high dissolved oxygen to form CO pores during casting solidification. |

| Reduction Duration | Outside 30-50 min range | 6 | 15.8 | Either insufficient for slag-metal reactions or excessive leading to temperature loss and reabsorption risks. |

The root cause analysis was clear: erratic control of carbon throughout the process—charge carbon, melt-out carbon, decarburization amount, end-point carbon, and final carbon—was the primary driver of process instability. This instability directly compromised degassing and deoxidation efficiency, making porosity in casting a statistically probable outcome. To combat this, we designed and implemented a comprehensive corrective action plan centered on process standardization, real-time control, and performance motivation.

Our first strategic move was to establish unambiguous, quantified technical indices for each process phase and link them to a transparent incentive scheme. This shifted focus from mere completion of tasks to achieving specific quality parameters known to suppress porosity in casting. The key performance indicators (KPIs) are summarized below.

| Process Phase | Control Parameter | Technical Index (Target) | Incentive Weight & Remarks |

|---|---|---|---|

| Melting | Melt-out Carbon Content | Conformance to SOP > 80% of heats | Critical metric. Failure to take corrective action if low is a veto for reward. |

| Corrective Action for Low C | 100% implementation when required | Veto item. Essential for enabling subsequent decarburization to prevent porosity in casting. | |

| Oxidation | Decarburization Amount (\(\Delta C\)) | \(\Delta C \geq 0.30\%\) (0.40% for critical castings) | Veto item. Fundamental for gas removal to avoid porosity in casting. |

| End-point Carbon Control | Conformance to SOP range (e.g., 0.18-0.25%) in > 70% of heats | Directly linked to reduction stability. | |

| Bath Temperature | Conformance to SOP > 90% of heats | Prevents overheating and associated gas solubility issues. | |

| Reduction | Final Carbon before Tap | Control within lower limit +0.03% to mid-range (e.g., 0.27-0.32%) in > 80% of heats | Minimizes need for late additions that can reintroduce porosity in casting. |

| Chemical Composition | 100% within specification limits | Veto item. Basic quality requirement. | |

| Reduction Time | 30 min ≤ t ≤ 50 min in > 90% of heats | Ensures adequate reaction time without excessive hold. | |

| White Slag Maintenance Time | ≥ 20 minutes as per SOP | Veto item. Critical for deep deoxidation to eliminate a root cause of porosity in casting. | |

| Tap Temperature | 100% conformance to SOP | Veto item. Affects fluidity and solidification pattern. | |

| Overall | General SOP Adherence | 100% for all other stipulated operations | Veto item. Ensures holistic discipline. |

Secondly, we overhauled the operational documentation. The existing操作规程 were revised and superseded by detailed, step-by-step Work Instructions (WIs). These WIs included decision trees for scenarios like low melt-out carbon. For instance, the procedure mandated: If \( C_{\text{melt-out}} < C_{\text{min, required}} \), then add calculated amount of recarburizer \( W_{\text{carb}} \) before oxidation, where:

$$ W_{\text{carb}} (kg) = \frac{(C_{\text{target}} – C_{\text{measured}}) \times \text{Heat Weight} (kg)}{\text{Recovery Factor} \times 100} $$

We conducted intensive training sessions for all furnace chiefs and operators, emphasizing the “why” behind each step—specifically its role in preventing porosity in casting. Supervisors were tasked with real-time monitoring and auditing to enforce compliance.

Third, we attacked potential external sources of gases. All furnace additives—lime, fluorspar, carburizer, and ferroalloys—were subjected to mandatory pre-heating or baking schedules to drive off moisture, a primary source of hydrogen. Lime showing signs of hydration and powdering was strictly quarantined. We switched from coarse to fine carbon powder for slag reduction, as its faster reaction speed promoted quicker formation of white slag, enhancing deoxidation efficiency and reducing the time window for gas pick-up.

Fourth, raw material management was tightened. Scrap and other charge materials were segregated and stored systematically to improve the accuracy of charge carbon calculations, directly addressing the main melting period flaw. The theoretical charge carbon was now calculated with a safety margin:

$$ C_{\text{charge, aim}} = C_{\text{final}} + \Delta C_{\text{ox, min}} + \Delta C_{\text{melting loss, max}} + \delta $$

where \( \delta \) is a small safety factor accounting for scrap variability.

Fifth, we institutionalized a culture of continuous learning and data analytics. Each shift began with a pre-heat meeting to review the previous heat’s data, discuss anomalies, and reinforce best practices. Every heat’s data was logged into a statistical process control (SPC) system. Monthly, we performed detailed analysis, calculating process capability indices like \( C_{pk} \) for key parameters:

$$ C_{pk} = \min\left(\frac{\text{USL} – \mu}{3\sigma}, \frac{\mu – \text{LSL}}{3\sigma}\right) $$

where USL/LSL are specification limits and \( \mu, \sigma \) are the process mean and standard deviation. Trends in these indices guided our technical meetings. For example, when end-point carbon control showed low \( C_{pk} \), we introduced a procedural change: mandatory slowdown of decarburization in the late oxidation phase with multiple carbon checks to improve hit rate. Such proven improvements were formally incorporated into the WIs.

The results of this multi-pronged assault on the process variables causing porosity in casting were systematically evaluated and were profoundly positive.

| Performance Metric | Pre-Intervention (Audit Phase) | Post-Intervention (First 3 Months) | Improvement & Significance |

|---|---|---|---|

| Hinge Girder Casting Yield (No Porosity) | ~80% | 100% | Elimination of scrap due to porosity in casting for this critical component. |

| Melt-out Carbon Conformance Rate | ~29% (in optimal range) | > 85% | Stable foundation for oxidation established. |

| Decarburization Amount Conformance (\(\Delta C \geq 0.3\%\)) | 50% | 100% (Veto enforced) | Guaranteed active carbon boil for degassing, directly attacking a root cause of porosity in casting. |

| White Slag Time Conformance (\(\geq 20\) min) | 60.5% | 100% (Veto enforced) | Ensured thorough deoxidation, removing another primary source of porosity in casting. |

| End-point Carbon Control (\(C_{pk}\) estimate) | < 0.5 (Poor) | > 1.33 (Capable) | Reduced variability, stabilizing the reduction period. |

| Overall Scrap Rate due to Gas Defects | High (Dominant cause) | Reduced by over 90% | Porosity in casting ceased to be the leading quality issue. |

The technical and cultural transformation was evident. The team’s theoretical understanding of the metallurgical principles behind gas defect formation deepened. Operatives moved from executing rote steps to actively controlling a process, understanding that each adjustment on carbon, temperature, or slag condition was a deliberate move to prevent porosity in casting. The SPC system provided objective evidence of improvement, fostering a sense of ownership and achievement. The success with the 35CrMo grade hinge girders was seamlessly replicated across other low-alloy steel grades, proving the robustness of the methodology. The financial impact was substantial, turning losses from porosity in casting into reliable profit. More importantly, it restored and enhanced customer confidence, securing future business.

In conclusion, the persistent challenge of porosity in casting is not an inevitability but a manageable consequence of process variability. Our experience demonstrates that a systematic, data-centric approach focusing on carbon control as the process linchpin is extraordinarily effective. By establishing clear, measurable indices, enforcing procedural discipline through training and incentives, controlling input materials, and fostering a culture of analysis and continuous improvement, it is entirely possible to master the melting process. The result is steel of consistently high purity, fundamentally incapable of forming the gaseous defects that manifest as porosity in casting. This holistic strategy of standardization, control, and refinement transcends a single product or furnace; it represents a blueprint for any foundry seeking to eradicate the scourge of porosity in casting and achieve world-class quality and reliability.