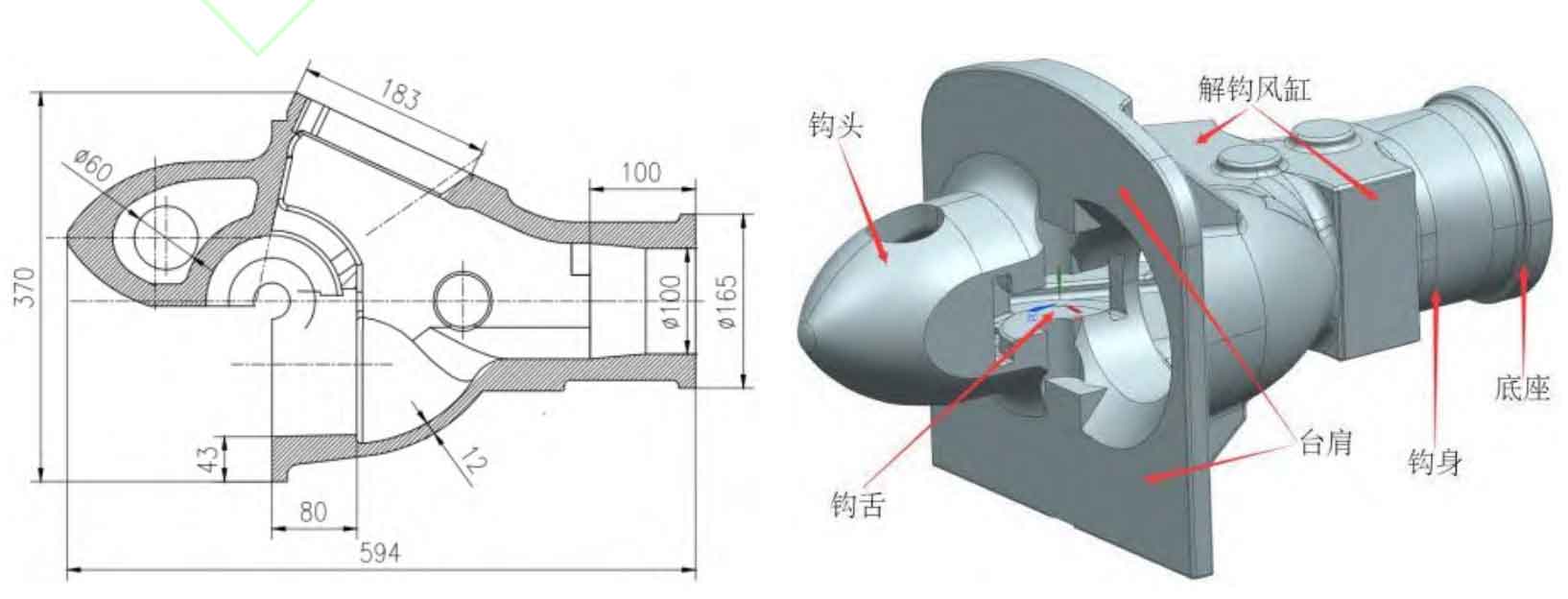

The blank size of coupler parts is large, and the outline is 594mm × 370mm × 350mm, which is a large investment casting with complex structure. The inner diameter of the bottom round hole R1 = 50mm, the radius of the round holes on both sides of the hook tongue R2 = 30mm, the thickness H1 of the thinnest part of the investment casting is about 12mm, the thickness H2 of the thickest part is 43mm, and the average wall thickness is greater than 15mm. The volume of the investment casting is v ≈ 9534593mm3, the surface area is S0 ≈ 871430mm2, the blank weight is about M ≈ 70kg, and the structure is shown in the figure.

The coupler has complex structure, wall thickness and large variation of wall thickness. The overall quality requirements of investment casting are high, and crack defects are not allowed. The material is domestic high-strength low-alloy Grade E steel ZG25MnCrNiMo, and its main chemical element content is shown in the table. Due to the existence of many small corners in investment castings, the mold filling capacity is reduced, and it is easy to produce defects such as under casting, inclusion, air entrainment and so on; At the same time, the wall thickness of investment castings varies greatly and the section mutation is more, which is easy to lead to hot spots and thermal stress, and finally form shrinkage, deformation, crack and other defects.

| Main chemical elements | C | Si | Mn | Cr | Ni | Mo | P | S | Fe |

| Regulations | 0.25-0.32 | 0.40-1.50 | 1.30-1.85 | 0.50-0.60 | 0.45-0.50 | 0.25-0.30 | ≤0.35 | ≤0.35 | — |

| Actual | 0.26 | 0.45 | 1.40 | 0.55 | 0.45 | 0.25 | ≤0.35 | ≤0.35 | Other |