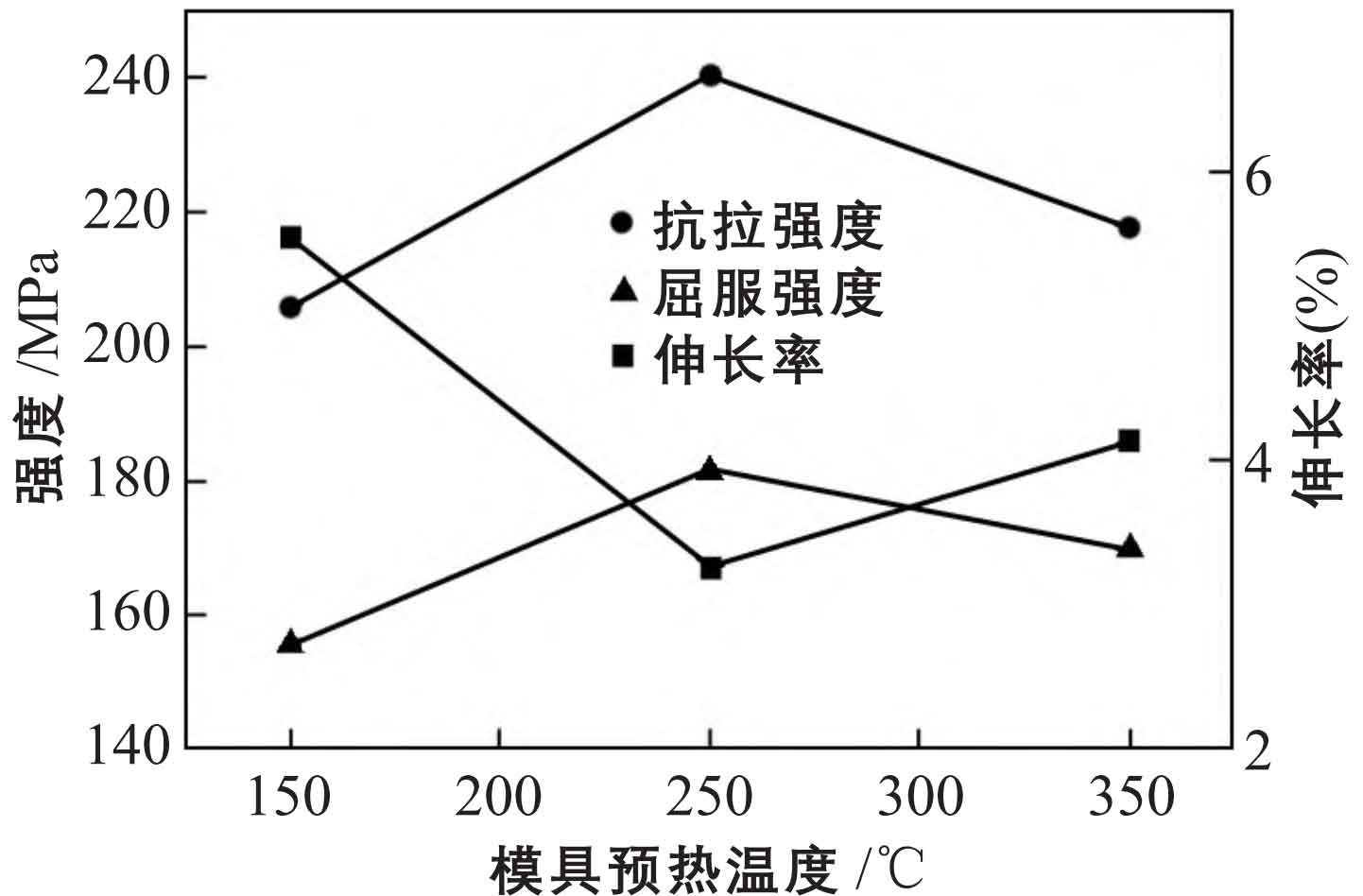

The mechanical properties of AlSi7Mg alloy specimens prepared at different mold preheating temperatures were tested under the same mold locking force, injection force, mold filling speed and casting temperature (700 ℃). The results are shown in Figure 1. It can be seen that the tensile strength and yield strength of AlSi7Mg aluminum alloy specimens show a trend of first increasing and then decreasing as the mold preheating temperature increases from 150 ℃ to 350 ℃. When the mold preheating temperature is 150 ℃, the tensile strength of the alloy is the lowest, 205.63MPa, and the yield strength is the lowest, 155.67MPa; When the preheating temperature of the die is increased to 250 ℃, the tensile strength of the alloy reaches the maximum value of 240.74MPa, the yield strength is 182.71MPa, the tensile strength is increased by 17.1%, and the yield strength is increased by 17.4%; With the preheating temperature of the die further increased to 350 ℃, the tensile strength of the alloy decreased to 217.69 MPa, the yield strength decreased to 169.79 MPa, the tensile strength decreased by 9.6%, and the yield strength decreased by 7.1%. The change of elongation of AlSi7Mg specimen is inversely proportional to the change of strength, with a trend of decreasing first and then increasing. When the mold preheating temperature is 250 ℃, the elongation of AlSi7Mg specimen is 5.47%; When the preheating temperature of the die rises to 250 ℃, the elongation decreases to the lowest, 3.23%; When the mold preheating temperature is 350 ℃, the elongation of the alloy increases to 4.10%. It can be seen from the above results that in order to obtain AlSi7Mg aluminum alloy specimens with better strength, the mold preheating temperature should be 250 ℃.

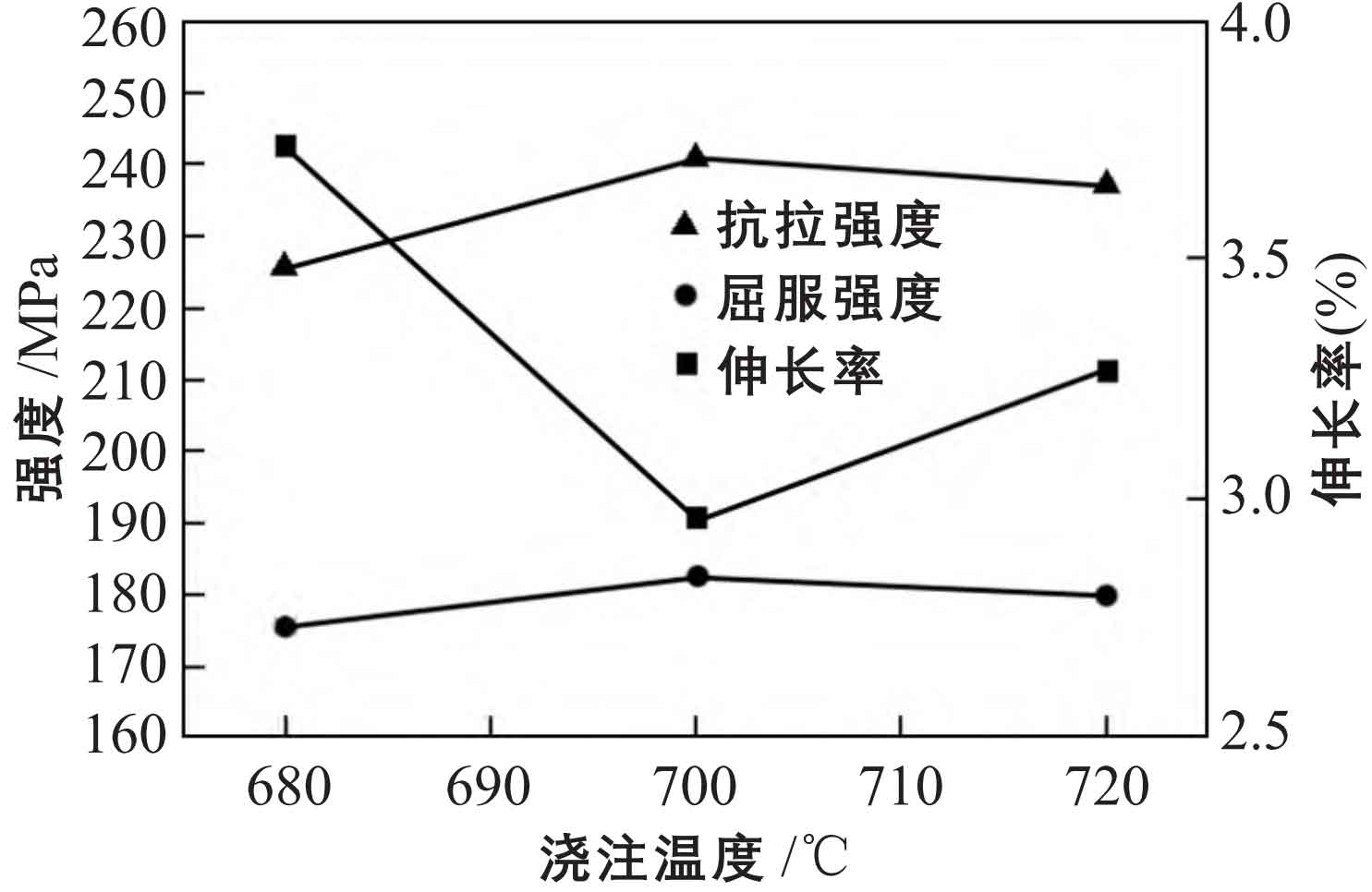

Similarly, under the same conditions of mold locking force, injection force, mold filling speed and mold preheating temperature (250 ℃), the mechanical properties of AlSi7Mg specimens prepared at different pouring temperatures were tested, and the results are shown in Figure 2. It can be seen from the figure that when the pouring temperature of die casting increases from 680 ℃ to 720 ℃, the tensile strength and yield strength of AlSi7Mg aluminum alloy specimens also show a trend of increasing first and then decreasing. When the pouring temperature is 680 ℃, the tensile strength of the alloy is at least 225.35MPa, and the yield strength is 175.61MPa; When the pouring temperature of the die casting process is raised to 700 ℃, the tensile strength of the alloy reaches the maximum value of 240.74MPa, increased by 6.8%, and the yield strength is 182.71MPa; With the pouring temperature of the die casting process further increased to 720 ℃, the tensile strength of the alloy decreased to 236.96 MPa, the yield strength was 179.19 MPa, the tensile strength decreased by 1.6%, and the yield strength decreased by 1.9%. The change trend of elongation of AlSi7Mg specimen is inversely proportional to the change of strength, which is the trend of decreasing first and then increasing. When the pouring temperature of die-casting process is 680 ℃, the elongation of AlSi7Mg specimen is 3.74%; When the pouring temperature of the die casting process rises to 700 ℃, the elongation decreases to the lowest, 2.96%; When the pouring temperature of the die casting process is 720 ℃, the elongation of the alloy increases to 3.27%. It can be seen from the above results that in order to obtain AlSi7Mg specimens with better mechanical properties, the pouring temperature of the die-casting process should be 700 ℃.