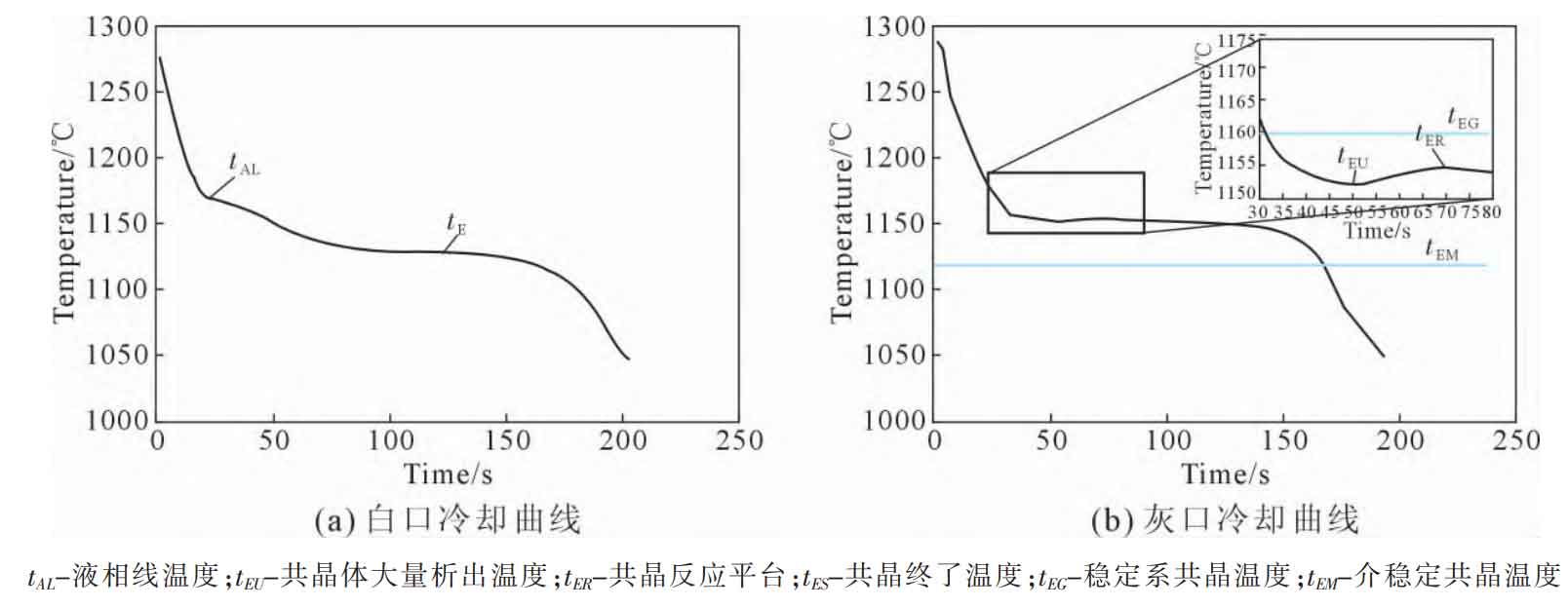

It can be seen from Fig. 1-2 that the inoculation of nodular cast iron can provide conditions for graphite nucleation, increase the number of graphite spheres and refine eutectic clusters in the production of nodular cast iron. The thermal analysis curve of molten iron provides the basis and convenience for the melt quality control of ductile iron production. It is helpful to understand the principle of melt quality control by using the thermal analysis curve of molten iron. As shown in Figure 3 (a), the white thermal analysis curve of molten iron in hypoeutectic state, tAL is the liquidus temperature, i.e. the initial crystallization point temperature, and tE is the white eutectic temperature. In Figure 3 (b), tEG is the theoretical temperature at which the graphite-austenite two-phase eutectic transformation begins. TEU is the precipitation temperature of eutectic and the lowest temperature of eutectic transformation. If there is no inoculation or insufficient inoculation after spheroidization, the number of nucleation cores is small, the number of eutectic clusters is small, resulting in little thermal effect, and the temperature of eutectic undercooling point (tEU) is low, forming a certain eutectic undercooling( Δ T=tEG-tEU)。 After tEU, a large amount of eutectic transformation and solidification latent heat were released, and the temperature rose to tER, and solidification entered the stage of eutectic austenite and graphite symbiosis. After the solidification of eutectic austenite forms a continuous solid, the non-solidified molten iron is enclosed in each isolated small molten pool. The solidification shrinkage of molten iron in the small molten pool will produce volume voids. If the liquid iron is not supplemented in time and the precipitated graphite is not expanded, these dispersed volume voids will form shrinkage porosity.

However, if the spheroidized molten iron is fully incubated, the nucleation conditions are good, and the number of eutectic clusters is large, the eutectic supercooling point at the beginning of eutectic solidification can be increased. Eutectic undercooling Δ T decreases, reducing the shrinkage probability. At the same time, the precipitation of eutectic graphite with more nucleation cores must be accompanied by graphitization expansion. After the eutectic austenite forms a continuous solid, the precipitated graphite fills the solidification shrinkage closed in the small molten pool, which can eliminate the shrinkage defects of cast iron and improve the quality of molten iron. As shown in Table 1, corresponding to the process parameters of different inoculation combinations, the liquid iron is close to the eutectic composition by adjusting the chemical composition. As the eutectic degree approaches to 1, the undercooling is also getting smaller and smaller.

Inverted inoculation and flow inoculation belong to strong inoculation and instantaneous inoculation, which is the most effective way to reduce undercooling. Strong inoculation and instantaneous inoculation can give a large number of core particles to molten iron, and prevent inoculation decay, which can ensure that there are enough graphite spheres in spheroidal graphite cast iron during eutectic solidification; The large and small graphite balls reduce the distance from the transfer of C in the liquid to the graphite core, accelerate the graphitization speed, and a large amount of eutectic solidification in a short time can release more latent heat of crystallization, reduce the degree of supercooling, not only prevent the formation of white mouth, but also strengthen the graphitization expansion.

| Serial number | Liquidus temperature tAL/℃ | Eutectic temperature tE/℃ | w(C)/% | w(Si)/% | Eutectic degree, Sc/℃ | Supercooling, Δ T/℃ | Spheroidization rate |

| ① | 1164 | 1123 | 3.67 | 1.69 | 0.97 | 6.7 | 84% |

| ② | 1161 | 1122 | 3.68 | 1.75 | 0.99 | 5.6 | 87% |

| ③ | 1155 | 1123 | 3.64 | 1.75 | 0.99 | 1.7 | 88% |

| ④ | 1154 | 1123 | 3.75 | 1.71 | 1.00 | 0.7 | 91% |

Therefore, strong inoculation is very important to improve the self-feeding ability of nodular cast iron. It can not only make the eutectic cluster small, achieve the purpose of fine grain strengthening, but also maintain high elongation while maintaining high strength of the casting body, so it is the key to do a good job of strengthening inoculation of nodular cast iron. The production of automobile steering knuckles uses the above inoculation principles to carry out multiple inoculation, including SiC pretreatment, floating silicon inoculation, wire feeding inoculation, ladle inoculation and flow inoculation. Through fine management, the eutectic degree of molten iron was adjusted to close to 1, and the eutectic undercooling of the solidification temperature curve was adjusted to the minimum value close to zero, eliminating shrinkage porosity. It is well known that the shrinkage porosity of castings will seriously affect the elongation. As shown in Table 2, the elongation of castings with shrinkage porosity defects is only 12.6%, while the elongation of the test bar of the steering knuckle body without shrinkage porosity reaches 20%, above 500 MPa, the yield strength is around 360 MPa, and the hardness is slightly increased.

| Metallurgical quality | Tensile strength/MPa | Yield strength/MPa | Elongation/% | Hardness (HB) |

| Steering knuckle casting with shrinkage porosity | 463 | 328 | 12.6 | 174 |

| Steering knuckle casting without shrinkage porosity | 508 | 360 | 20 | 188 |