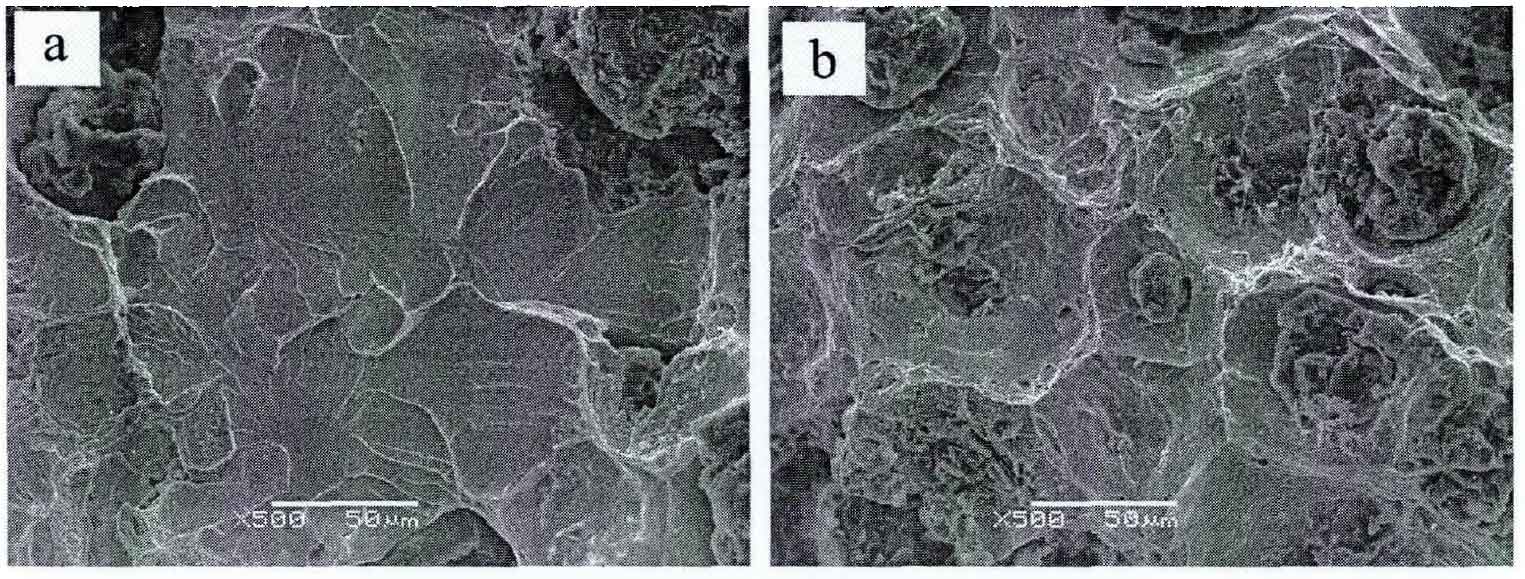

As shown in Figure 1, the scanning photo of impact fracture micro morphology of B2 sample of nodular cast iron in as cast state is shown.

It is found that the micro morphology of ductile iron fracture is composed of cleavage fracture and quasi cleavage fracture. The fracture shape of cleaved ductile iron is shown in Figure 1a, which is characterized by flat and smooth cleavage surface, obvious cleavage steps and river pattern. Cleavage fracture has little plastic deformation and obvious brittle characteristics. The fracture shape of quasi cleavage nodular cast iron is shown in Fig. 1b, which is characterized by discontinuous expansion surface, a large number of tear edges and dimple bands around the graphite ball, short and curved lines, and the grain shape is concave basin. Quasi cleavage is a discontinuous fracture process, and large plastic deformation occurs during crack connection, so it shows good toughness.

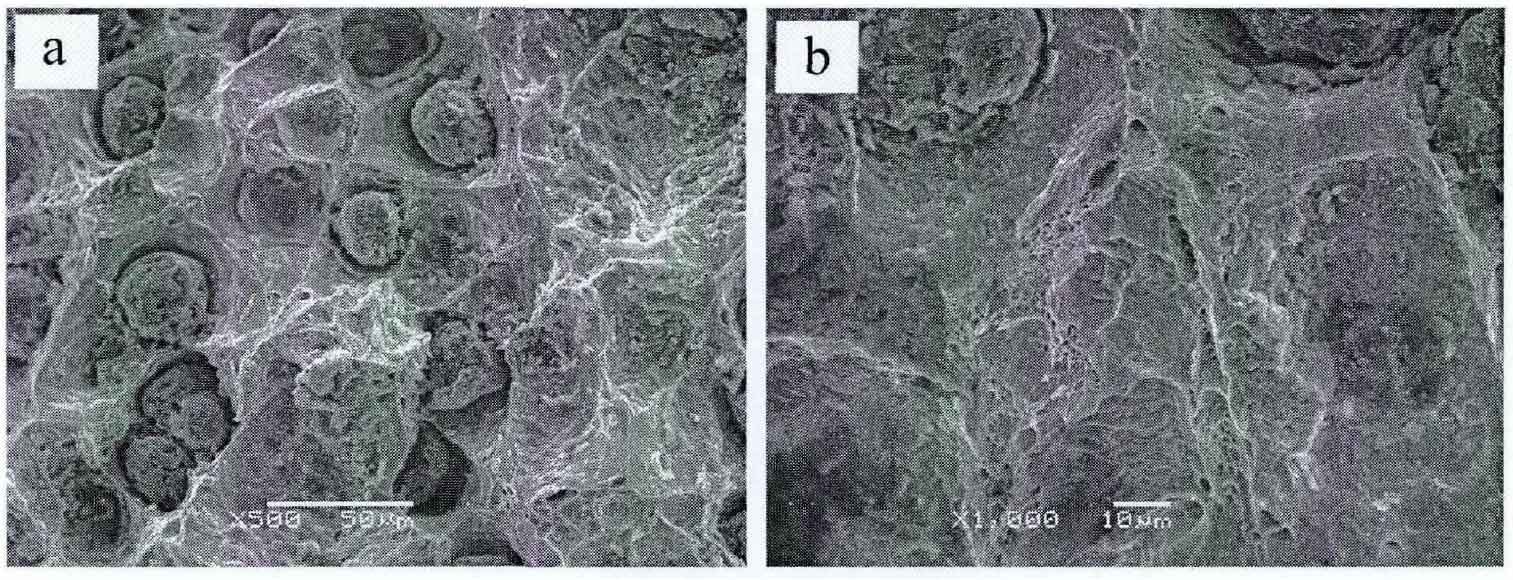

Fig. 2 is a scanning photo of the micro morphology of impact fracture of nodular cast iron under heat treatment.

It is found that the micro morphology of the fracture of nodular cast iron under heat treatment is a quasi cleavage fracture with good toughness. The graphite ball is embedded in the matrix, as shown in Fig. 2A. There are a large number of tearing edges and dimples around nodular cast iron graphite balls, which are more densely distributed, as shown in Fig. 2B. This shows that the impact toughness of the sample is improved after heat treatment.

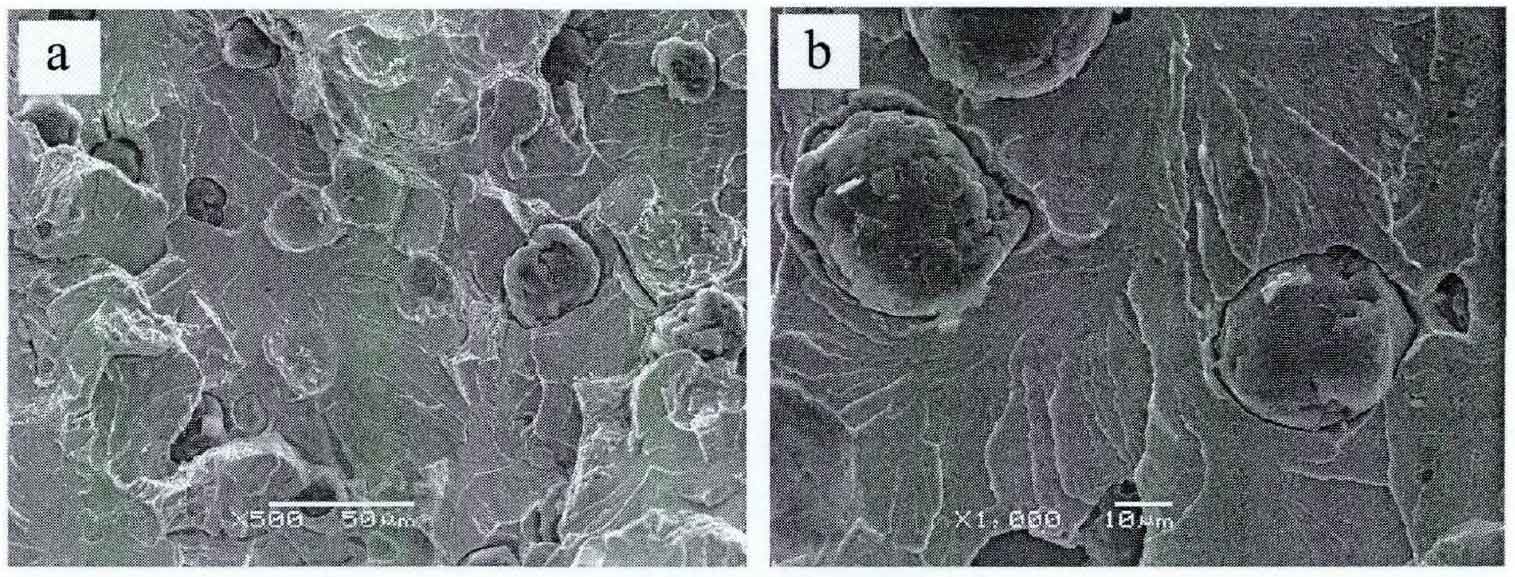

Fig. 3 is a scanning photo of the micro morphology of impact fracture of nodular cast iron in as cast state.

It can be seen from Figure 3 that the micro morphology of ductile iron fracture is mainly composed of cleavage fracture in river pattern. Some graphite balls in the matrix are stripped off, as shown in Fig. 3a. There are obvious cleavage steps on the matrix, and the lines of river pattern are connected with the gap between the graphite ball and the matrix, which expands and intersects outward from the graphite ball, as shown in Fig. 3B. It can be seen that nodular cast iron graphite ball is the root of crack, and a large number of cracks will be produced in the matrix during the fracture process. When the roundness of graphite ball is not high and there is a sharp angle at a certain place, it will promote the rapid formation and propagation of cracks and cleavage fracture of the matrix.

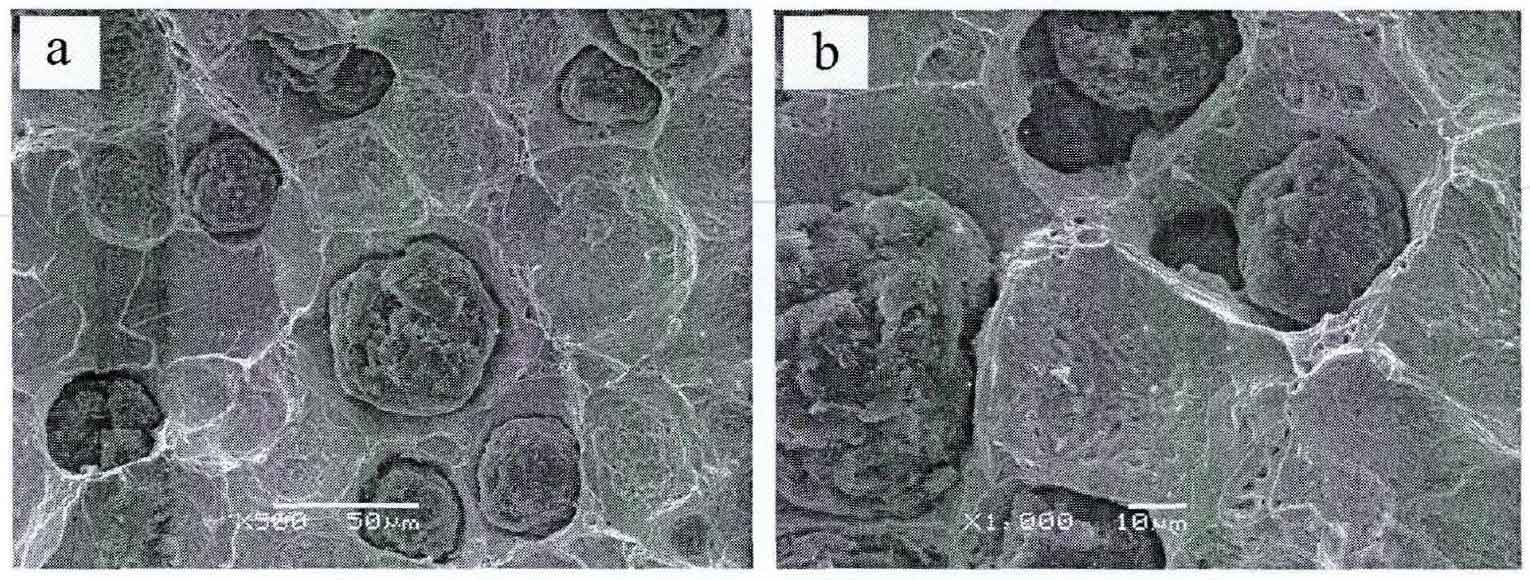

Fig. 4 is a scanning photo of the impact fracture micro morphology of the sample of nodular cast iron under heat treatment. It can be seen from FIG. 4A that the micro morphology of ductile iron fracture is composed of cleavage fracture and quasi cleavage fracture. A few cleavage fractures are found in the figure, and there are a few river patterns on the cleavage surface, which is characterized by brittle fracture. At the same time, it can also be seen that there are obvious tearing edges and dimple bands around the graphite ball of nodular cast iron. As shown in Fig. 4b, the matrix has undergone large plastic deformation, making the graphite ball embedded in it.

Through the analysis of the micro morphology of the impact fracture of nodular cast iron, it can be seen that when nodular cast iron shows great brittleness, the micro morphology is mainly smooth cleavage fracture, the graphite ball appears peeling, and the gap between the graphite ball and the matrix will become the root of the crack. At this time, the influence of graphite morphology on the impact toughness will be more obvious. When nodular cast iron shows certain toughness, the micro morphology is quasi cleavage fracture, a large number of tear edges and dimple bands appear around the graphite, and the matrix produces large plastic deformation, so that the graphite ball is embedded in it. In order to improve the impact toughness of nodular cast iron, the shape of graphite ball should be round while ensuring the toughness of matrix, so as to avoid crack sensitive areas such as sharp corners.