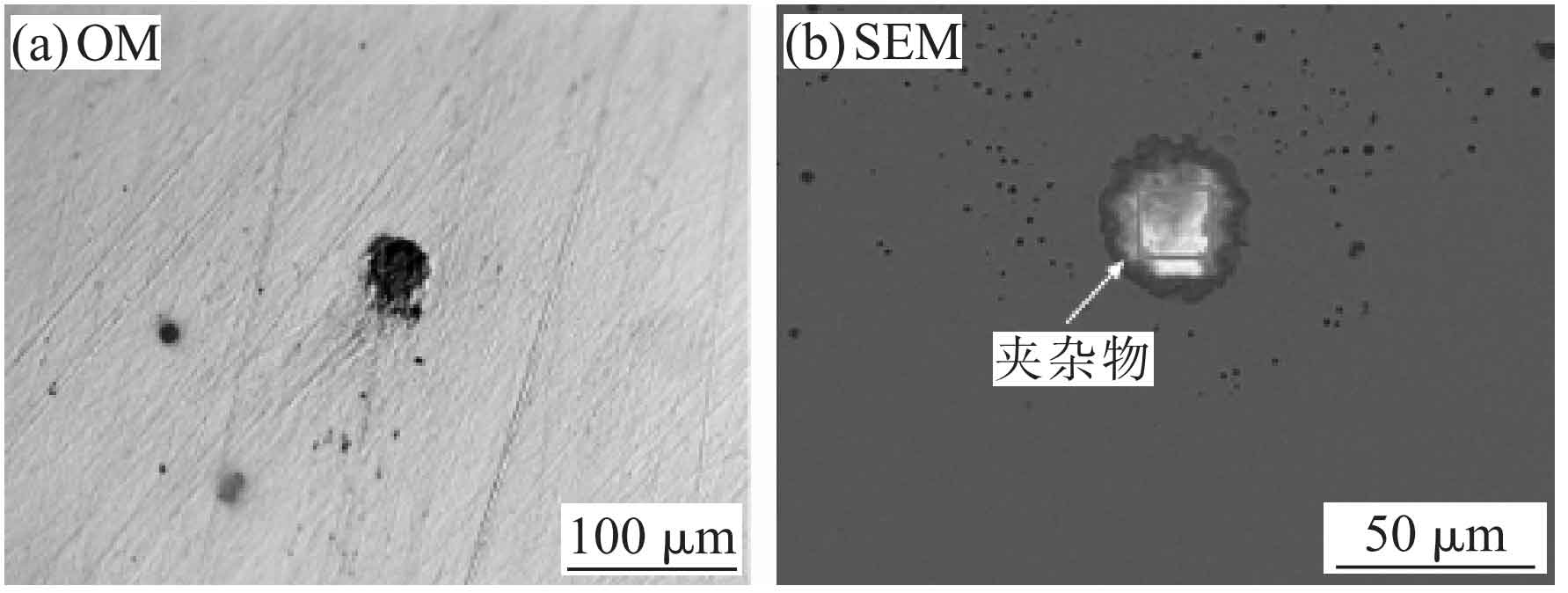

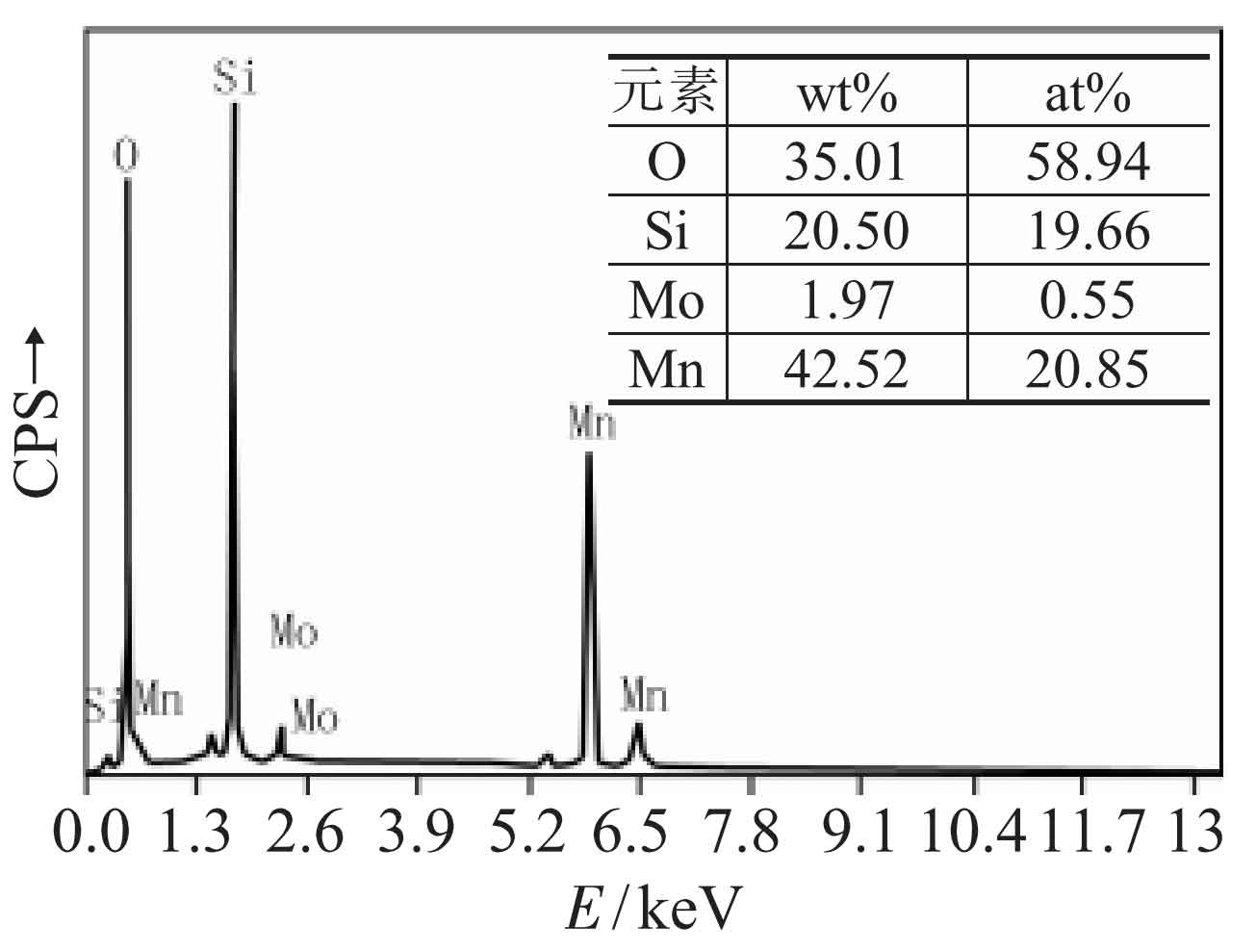

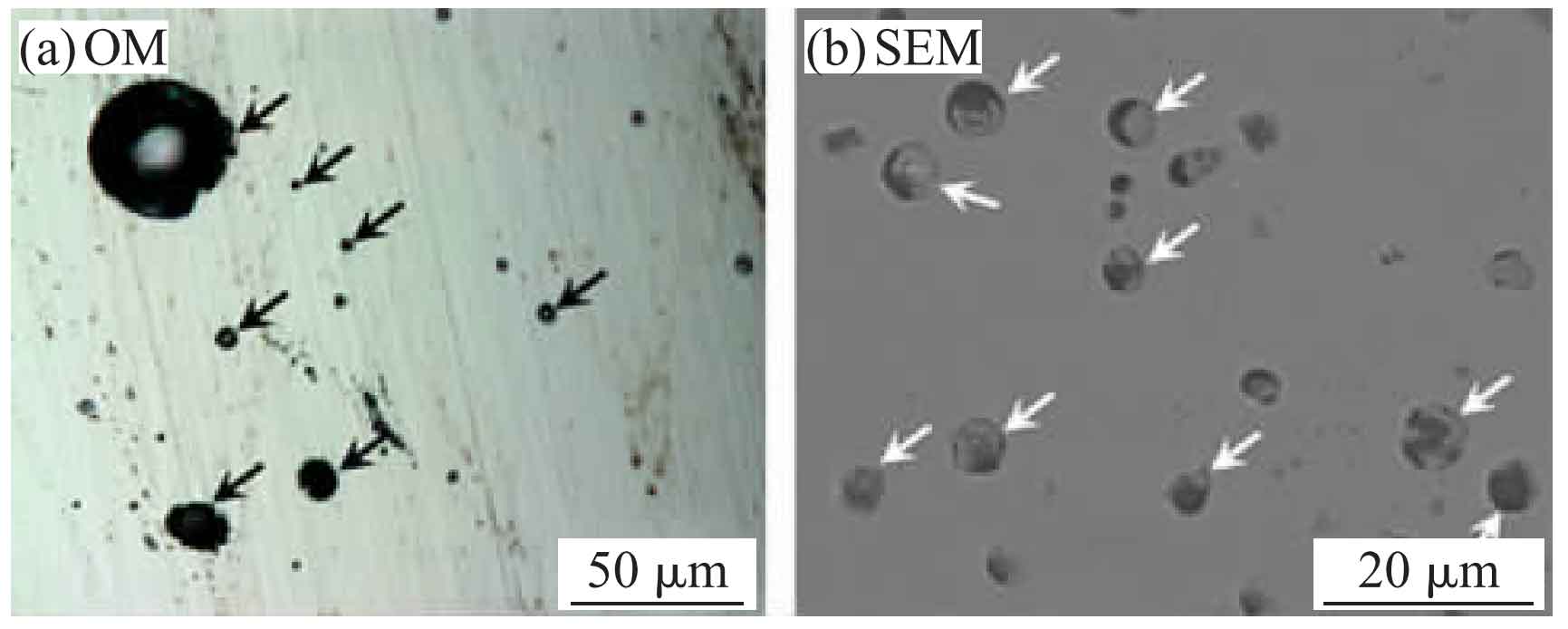

Two different MNS inclusion defects were observed in cast steel. Fig. 1 shows the microscopic morphology of the first MNS inclusion defect observed. The inclusion defect is dispersed in the cast steel and has a small number, but the size is relatively large. It can be seen from Fig. 1 (a) that such inclusion defects appear as black flocculent under the metallographic microscope. Under the backscattered electron image of SEM, it can be seen that the inclusion defect is composed of two parts, the central part is white, and the outer layer is gray (as shown by the arrow in Fig. 1 (b)). This shows that there are differences in chemical composition between the inner and outer layers of the inclusion defect. The results of energy spectrum analysis on the core region of the inclusion are shown in Figure 2. It can be seen that the central region of the inclusion mainly contains Si, Mn and O, and its atomic percentage is about 20 ∶ 20 ∶ 60, which is converted into the molecular number ratio of MnO to SiO2 is about 1 ∶ 1. Therefore, it can be basically determined that the white area in the center of the inclusion is mainly composed of MnO and SiO2 oxides, and the ratio of the two oxides is close to 1 ∶ 1, which is a mno-sio2 inclusion defect.

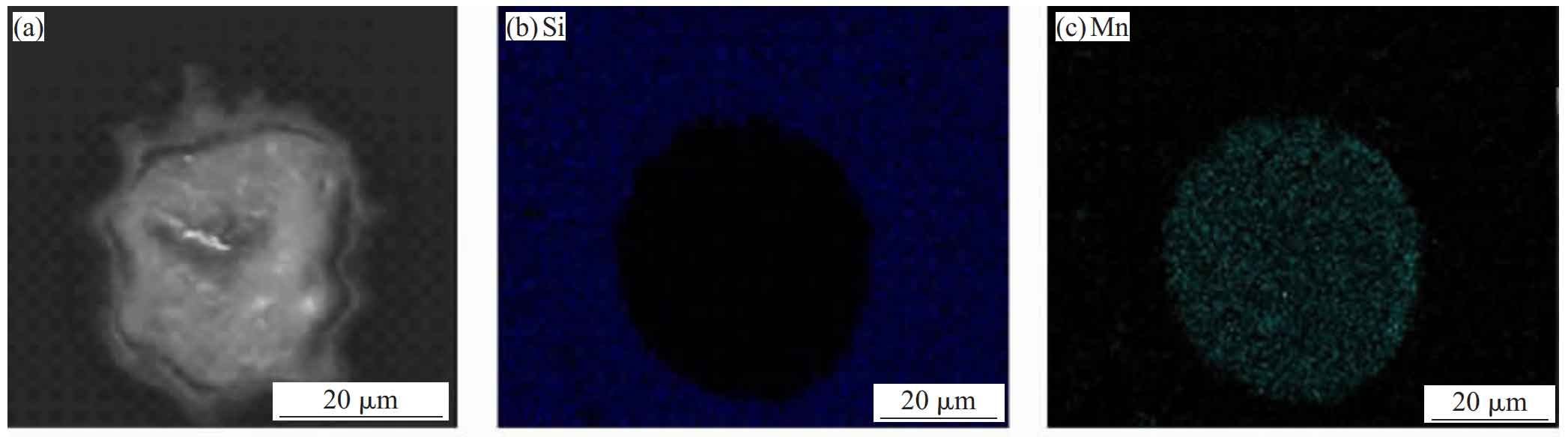

In order to further analyze the element distribution of each part of the inclusion defect, EDX surface scanning analysis is carried out for the inclusion defect, and the analysis results are shown in Fig. 3. It can be seen from Figure 3 that in addition to Si, Mn and O, there is a small amount of S element in the inclusion defect, as shown in Figure 3 (E). S element is mainly distributed in the peripheral black area of the inclusion defect. Combined with the distribution of Mn and O elements shown in Fig. 3 (c) and (d), it can be determined that the white area in the center of the inclusion defect is mainly composed of MnO and SiO2 oxides, while the peripheral black area is mainly composed of MNS. Therefore, the inclusion defect is a mixed inclusion covered with MNS on the surface of mno-sio2 inclusion defect.

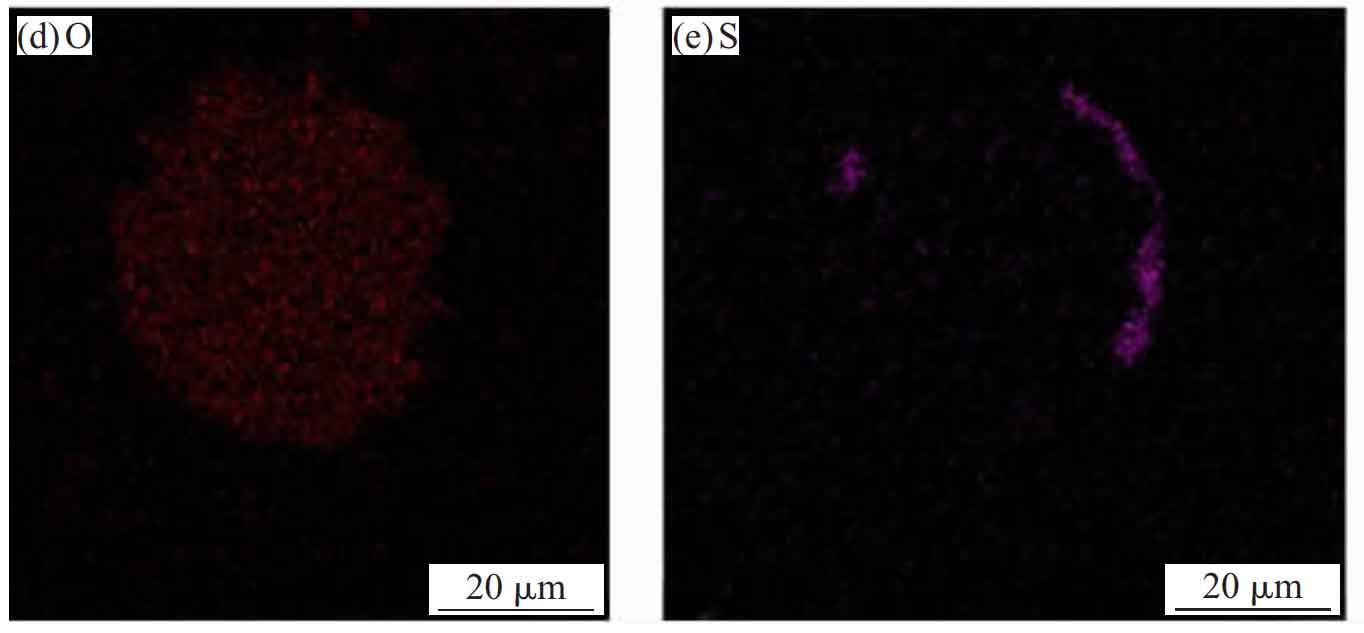

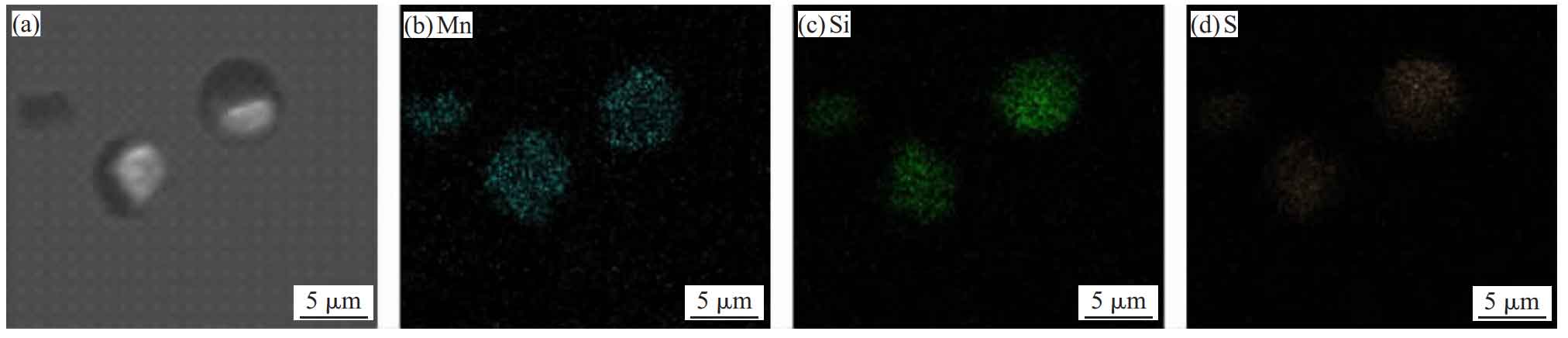

Figure 4 shows the microstructure of the second MNS inclusion defect observed in cast steel. When observed under the metallographic microscope, this MNS inclusion defect is a black and spherical inclusion with regular shape (shown by the black arrow in Fig. 4 (a)). When the backscattered electron image is used for observation under the scanning electron microscope, the inclusion is half black and half gray white spherical (shown by the white arrow in Fig. 4 (b)), indicating that the MNS inclusion defect has a certain regionality in the element distribution, and there is a difference in the element composition between the black region and the gray white region. In terms of size, the diameter of such MNS inclusion defects ranges from a few microns to tens of microns. In terms of distribution, the number of such MNS inclusion defects in steel castings is more, but the distribution is very uneven, showing a concentrated distribution in some areas.

Figure 5 shows the EDX surface scanning analysis results of the second MNS inclusion defect. It can be seen from the surface scanning analysis results that the gray white area of MNS inclusions shown in Fig. 5 (a) is mainly composed of Mn and Si elements, which are oxides of Mn and Si; The black area is mainly composed of Mn and S elements, which is MNS. It can be seen that the MNS inclusion defect is very similar to the MnO MNS inclusion defect shown in Figure 1 in chemical composition, which is composed of Mn and Si oxides and MNS attached to them. Although the two kinds of MNS inclusion defects have some differences in microstructure, their morphological characteristics show that there is a close relationship between the formation of MNS inclusion defects and oxidized inclusions such as MnO and SiO2.