Abstract: The methods of regulating the microstructure of steel castings during the solidification stage, aiming to enhance their functionality and broaden their application fields. By examining heat transfer and mass migration phenomena in the solidification process based on thermodynamic principles, and exploring the dynamic mechanisms underlying microstructure formation, we discuss the effects of critical technologies such as cooling rate, alloy composition introduction, and numerical analysis on the microstructure. Through case studies, we reveal the effectiveness of microstructure control techniques in specific environments and their impact on improving product quality. Our findings indicate that strictly adjusting the microstructure of steel castings can significantly enhance their mechanical properties and durability, playing a pivotal role in advancing materials engineering and manufacturing industries.

1. Introduction

Steel castings occupy an important position in the industrial field due to their excellent mechanical properties and widespread applications. The final properties of steel castings largely depend on the microstructure formed during the solidification process. This paper will conduct in-depth research on the control techniques of the microstructure during the solidification of steel castings, exploring how to optimize the microstructure by precisely regulating solidification conditions to improve the overall performance of steel castings.

2. Fundamental Theory of the Solidification Process of Steel Castings

2.1 Thermodynamic Principles in the Solidification Process of Steel Castings

The solidification process of steel castings follows the First and Second Laws of Thermodynamics. The First Law, also known as the Law of Conservation of Energy, ensures the conversion and transfer of energy during solidification. As the temperature of the molten steel decreases, its internal energy diminishes, releasing latent heat. This latent heat is transferred to the surrounding environment through conduction, convection, and radiation. The Second Law, or the Principle of Increasing Entropy, states that in spontaneous processes, the entropy of the system tends to increase. During the solidification of steel castings, as the solid phase forms, the system entropy increases, driving the spontaneous progression of the solidification process.

2.2 Heat Transfer and Mass Transfer Phenomena in the Solidification Process

Heat transfer and mass transfer are two crucial physical phenomena in the solidification process of steel castings. Heat transfer primarily involves the transfer of heat from high-temperature regions to low-temperature regions, occurring through three basic modes: conduction, convection, and radiation. Conduction is the primary mode of heat transfer within solids, while convection is more significant in liquids, particularly during the initial cooling stage of castings, where it can significantly accelerate heat transfer. Mass transfer involves the diffusion of alloy elements at the solid-liquid interface, determining the distribution of alloy elements in the casting and affecting its microstructure and properties.

2.3 Dynamic Mechanisms of Microstructure Formation

The formation of microstructure is a kinetic process involving the adsorption, diffusion, and arrangement of atoms or molecules at the interface. In the solidification process of steel castings, factors such as crystal growth rate, grain size, grain orientation, and nucleation and growth of the second phase are key in influencing the microstructure. The crystal growth rate depends on the temperature gradient and cooling rate, while grain size is influenced by the cooling rate and alloy element content. Grain refinement can improve the strength and toughness of castings, while the nucleation and growth of the second phase can enhance hardness and wear resistance. By precisely controlling these kinetic parameters, the microstructure of steel castings can be optimized to achieve desired properties.

3. Key Techniques for Microstructure Control

3.1 Effect of Cooling Rate on Microstructure

The cooling rate is considered one of the main variables determining the formation of microstructure in cast steel products. The speed of this cooling process directly affects the rate of crystal growth and grain size. Rapid cooling typically results in fine and dense crystals, which enhance material hardness and flexibility. However, extreme cooling rates may also induce stress accumulation and microcracks within the casting, compromising structural integrity. Conversely, during slower cooling, crystal growth may be enhanced, leading to the formation of coarser grain structures, potentially reducing hardness but enhancing ductility.

Table 1: Microstructure and Performance Data Under Different Cooling Rates and Alloy Element Addition Conditions

| Case No. | Cooling Rate (℃/s) | Added Elements | Grain Size (μm) | Yield Strength (MPa) | Impact Toughness (J/cm²) | Hardness (HB) |

|---|---|---|---|---|---|---|

| Case 1 | 50 | V, Nb | 50 | 1000 | 200 | 250 |

| Case 2 | 30 | Mn | 100 | 900 | 180 | 240 |

| Case 3 | 20 | Ti | 200 | 800 | 150 | 230 |

From Table 1, we observe that as the cooling rate increases (from 20℃/s in Case 3 to 50℃/s in Case 1), grain size significantly decreases, leading to improved yield strength and impact toughness. Case 1, with the highest cooling rate, exhibits the finest grains and thus the highest yield strength and impact toughness. The addition of different alloy elements also has a significant impact on the microstructure and properties of steel castings. For instance, adding V and Nb in Case 1 not only refines grains but also enhances material hardness.

3.2 Alloy Element Addition and Microstructure Regulation

Introducing alloy elements is an effective strategy for adjusting the microstructure of cast steel products. Different alloy elements exert varied effects on the solidification process and microstructure of cast steel. For example, carbon and manganese are well-known alloy elements that influence steel strengthening and flexibility. Carbon atoms, by forming carbides, enhance hardness and wear resistance, while manganese improves steel strength and ductility. Trace elements such as vanadium, niobium, and titanium can refine grain structure by forming stable carbides or nitrides, thereby enhancing material microstructure.

3.3 Numerical Simulation and Optimization of Microstructure

Numerical simulation provides an effective and precise means for controlling the microstructure of steel castings. Utilizing computer simulation technology, we can predict changes in the microstructure of cast steel under various cooling rates and alloy compositions. These simulations encompass dynamic processes from crystal nucleation, initial solidification of grains, to their growth, as well as the initial formation and expansion of secondary phases. Numerical simulation can assist scientists and engineers in estimating and enhancing casting performance before actual manufacturing, reducing the frequency and cost of repeated experiments.

4. Application Case Studies of Microstructure Control Techniques

4.1 Microstructure Optimization of Steel Castings Under Specific Conditions

In specialized industrial scenarios, such as the production of high-speed train wheel hubs, stringent requirements are imposed on the wear resistance and elasticity standards of cast steel materials. By altering cooling rates and alloy compositions, research teams have effectively improved the microstructure of wheel hub steel. For instance, in one experiment, by slowing the cooling rate to 50℃/s and adding appropriate amounts of vanadium and niobium, researchers successfully achieved significant grain refinement, reducing the average grain size from 200 micrometers to 50 micrometers. This microstructural transformation led to a roughly one-fifth increase in the yield strength of wheel hub steel, rising to 1000 MPa, and a nearly 30% increase in impact toughness, up to 200 J/cm². These data adequately demonstrate the effectiveness of microstructure management techniques in enhancing the quality of cast steel products.

4.2 Application of Microstructure Control Techniques in Different Industries

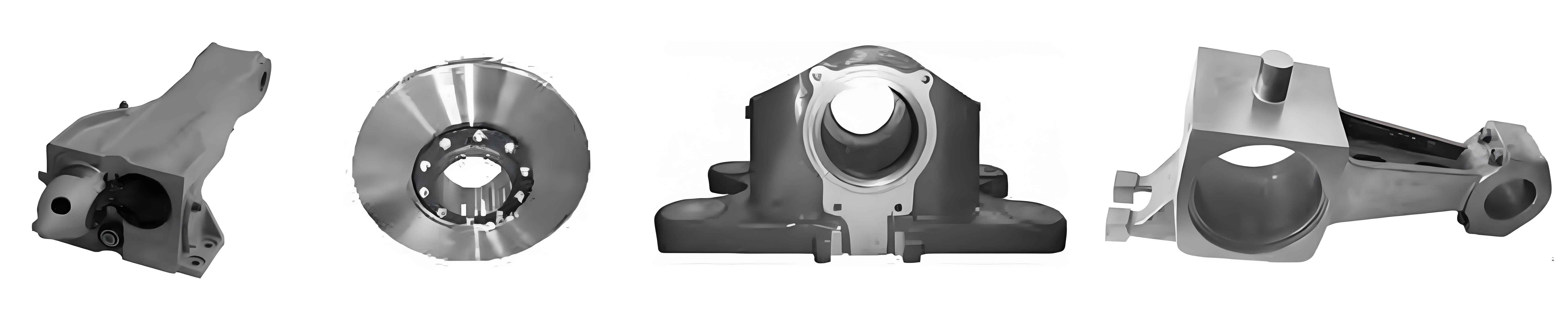

Microstructure regulation techniques are widely used in various industries. In the automotive industry, by precisely controlling cooling rates and alloy compositions, engine cylinder wall materials with exceptional fatigue resistance can be produced. In the aerospace industry, by improving microstructure, lightweight aircraft components with ultra-high endurance can be manufactured. In a research project on aluminum alloys for aerospace applications, researchers effectively increased the tensile yield strength of the alloy to 500 MPa while maintaining excellent ductility by altering cooling rates and incorporating an appropriate proportion of scandium (Sc). The application of these techniques not only enhances product stability and safety but also supports technological advancements in the industry.

4.3 Enhancement of Product Quality through Microstructure Control Techniques

Microstructure regulation techniques have a notable impact on improving product performance. In an experiment involving large steel castings, the use of computational simulation to adjust cooling rates and alloy elements effectively reduced internal defects by half and increased the durability of refined grain castings by approximately 40%. In a different study, by adjusting the microstructure of a high-manganese alloy, researchers successfully increased its hardness by 15%, reaching HB500, while maintaining its inherent high ductility. These data indicate that by employing microstructure regulation techniques, not only can the mechanical strength of cast steel products be significantly enhanced but their durability can also be increased, contributing to improved product quality.

5. Future Developments in Microstructure Control Techniques for Steel Castings

The pursuit of innovative cast steel materials aims to achieve substantial performance enhancements by meticulously adjusting chemical compositions and microstructures. A pivotal strategy in this endeavor is the incorporation of nanoscale rare earth elements into steel. These elements can dramatically refine grain structure, thereby bolstering material hardness and flexibility.

In a pioneering scientific study, the introduction of just 0.03% rare earth metals into steel resulted in a remarkable reduction in grain size, from 150 micrometers to 10 micrometers. This transformation led to a significant enhancement in the material’s resistance to deformation and impact toughness. Such findings underscore the profound impact of nanoscale rare earth components on the microstructural properties of steel.

Moreover, the exploration of novel steel grades with unique microstructure attributes, such as ultrafine-grained steel and heterogeneous microstructure steel, represents a burgeoning trend in future research. These advanced materials offer the potential for even greater performance enhancements through tailored microstructural characteristics.

The development of new steel casting materials, therefore, hinges on a deep understanding of microstructure control techniques. By leveraging advancements in materials science and engineering, researchers can fine-tune chemical compositions and microstructures to tailor the properties of cast steel to meet specific application requirements. This approach not only enhances material performance but also paves the way for the development of more efficient and sustainable manufacturing processes.