High chromium cast iron needs heat treatment to obtain the best comprehensive properties. High temperature austenitizing destabilization treatment and medium temperature subcritical treatment are common heat treatment processes for high chromium cast iron. There are many studies on the micro transformation of high chromium cast iron in different heat treatments at home and abroad.

After treatment, the matrix structure of high chromium cast iron is transformed from original austenite (Fig. 1) to martensitic (Fig. 2) carbides, showing fine strip and chrysanthemum shape. In addition, some granular, dispersed and rod needle shaped secondary carbides are distributed around the newly formed matrix. Similar secondary carbides are also obtained by using similar high chromium cast iron components.

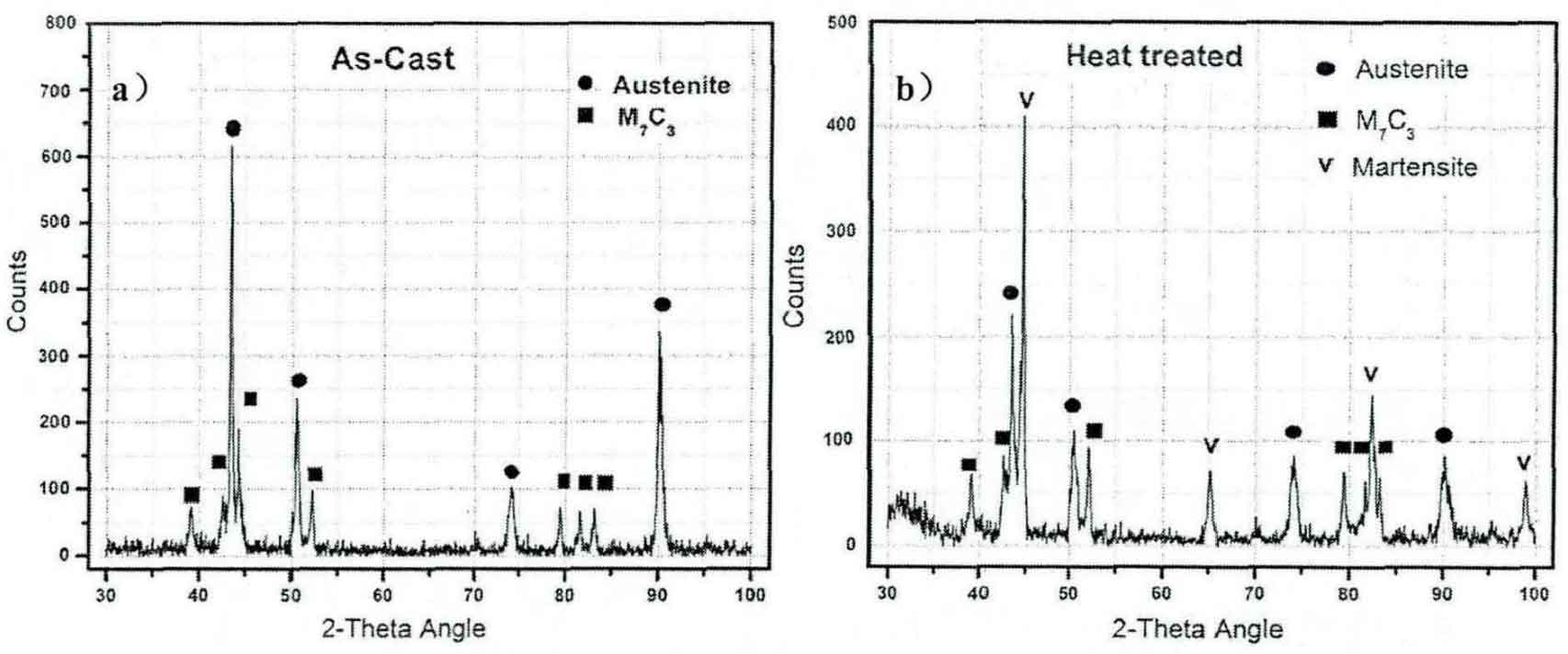

In addition, through the X-ray diffraction analysis of high chromium cast iron as cast and heat treated, as shown in Figure 3a, according to the diffraction peak, the as cast high chromium cast iron sample is mainly composed of austenite and eutectic carbide; As shown in Fig. 3b, according to the diffraction peak, the heat-treated high chromium cast iron sample is mainly composed of martensite, austenite and eutectic carbide. Compared with the diffraction results of the as cast sample, the original austenite phase diffraction peak intensity is significantly reduced, while the martensite phase diffraction peak intensity is significantly increased, The results of X-ray diffraction analysis further prove that the metallographic analysis described above is correct and reasonable.

To sum up, as cast austenite contains high carbon and chromium and is relatively stable. After destabilization heat treatment, it is reheated to the austenitizing temperature and kept warm, so that chromium and carbon precipitate in the form of secondary carbides. After destabilization, the austenite temperature increases and becomes unstable, and transformation into martensite occurs. This process is called destabilization. In addition, the destabilization effect is related to the as cast structure. According to the solidification transformation theory under equilibrium conditions, the original grains are surrounded by intermittent eutectic carbides, which are respectively pearlite zone, martensite zone and austenite zone from the edge to the center. The secondary carbides generated after destabilization are divided into rod needle, dispersed and granular, with high carbon and chromium content in the center, In order to balance its reduction, it must be through diffusion.

Due to the extremely slow diffusion in the austenite zone, it is difficult to reach equilibrium under normal heating and insulation conditions. As a result, austenite destabilization is incomplete. Secondary carbide precipitated from austenite plays a dominant role in the transformation characteristics of high complex cast iron. It occurs not only in the above austenitization process, but also in the continuous cooling process to control the destabilization during heat treatment, It is to control the phase transformation of castings during continuous cooling.