The persistent challenge of porosity in casting represents a significant hurdle in achieving high-quality, reliable aluminum die-cast components. As someone deeply involved in the intricacies of the die-casting process, I have observed that while metallurgical factors are often scrutinized, the dynamic conditions within the die cavity during filling are frequently overlooked. This article presents a comprehensive investigation into the critical relationship between injection parameters, in-cavity gas pressure, and the resultant formation of porosity in casting. The central hypothesis, confirmed through detailed experimentation, is that a direct and controllable link exists: by strategically lowering the gas pressure at the final filling locations, the local metal velocity can be significantly increased, thereby drastically reducing or eliminating defects associated with porosity in casting.

The economic and technical imperative to minimize scrap rates and enhance product integrity in die casting cannot be overstated. Defects like porosity in casting compromise mechanical strength, pressure tightness, and surface finish, leading to part rejection. The genesis of this porosity in casting is multifactorial. It stems not only from the inherent gas content of the molten aluminum alloy but, crucially, from the turbulent entrapment of air residing in the die cavity prior to injection. The conventional focus on parameters like metal temperature, die temperature, and specific pressure, while important, often misses the nuanced interplay between the advancing molten metal front and the displaced/entrapped air. My research specifically targets this gap, analyzing how the filling speed decays along the flow path and how this decay is intrinsically governed by the rising counter-pressure from compressed gases within the cavity.

The fundamental problem can be described as a competition between two opposing pressures. The driving force is the hydraulic pressure from the injection system, which imparts kinetic energy to the molten metal. The resisting force is the pressure of the gas (primarily air) being compressed ahead of the liquid front and in isolated pockets. When the local metal velocity drops below a critical threshold, it loses the energy required to force trapped gas into solution or to push it into overflow wells; instead, the gas becomes encapsulated, forming porosity in casting. This phenomenon is particularly severe in the last regions to fill, where gas is most concentrated and metal momentum is at its lowest. The relationship can be conceptualized by considering a simplified force balance at the liquid front:

$$ P_{injection}(x) – P_{gas}(x) = \frac{1}{2} \rho v(x)^2 + \text{losses} $$

Where $P_{injection}(x)$ is the effective metal pressure at point $x$, $P_{gas}(x)$ is the local gas pressure, $\rho$ is the metal density, and $v(x)$ is the local fill velocity. As $P_{gas}(x)$ increases along the filling path, $v(x)$ must decrease if $P_{injection}(x)$ cannot compensate sufficiently, leading to conditions ripe for defect formation.

Experimental Methodology

To quantify these relationships, a controlled experimental study was designed and executed. A flat-plate die-casting geometry was selected as the test specimen, providing a clear and measurable flow path. The alloy used conformed to a standard Al-Si series, similar to A360, prepared under controlled melting and degassing practices to establish a consistent baseline for gas content. A horizontal cold-chamber die-casting machine was employed for all trials.

The core of the experimental setup involved the simultaneous measurement of two key variables along the metal flow path: local metal arrival velocity and local in-cavity gas pressure.

- Velocity Measurement: Specialized flow sensors were embedded at strategic points along the cavity, from near the gate to the overflow well. These sensors detect the precise moment the molten metal passes their location. The fill velocity $v$ at a sensor located a distance $L$ from the gate is calculated from the time difference $\Delta t$ between its triggering and the gate sensor’s trigger: $$ v = \frac{L}{\Delta t} $$ The system sensitivity allowed for velocity measurements with an accuracy better than 0.1 m/s.

- Gas Pressure Measurement: To measure the transient gas pressure without metal intrusion, small vertical vents were drilled at test locations. The cavity-end of these vents was fitted with a porous ceramic plug, which allowed air to pass but blocked molten metal. The external end was connected to a high-response piezoelectric pressure transducer. This setup provided real-time pressure traces during the filling event.

The sensor positions were designated to map the progression from the gate (‘G’) to the final fill area near the overflow (‘OF’). Additional venting modifications were part of the experimental variables. A summary of the constant process parameters is provided in Table 1.

| Parameter | Value / Specification |

|---|---|

| Casting Machine Type | Horizontal Cold Chamber |

| Part Weight (approx.) | 500 g |

| Alloy Type | Al-Si (A360 equivalent) |

| Pouring Temperature | 680 ± 5 °C |

| Part Thickness | 3 mm |

| Slow Shot Speed | 0.2 – 0.3 m/s |

| Fast Shot Speed (Nominal) | 4.0 m/s |

The experimental variables were the shot profile and the venting configuration at the end-of-fill location. Three primary conditions were tested:

- Condition A (Baseline): Single-stage high-speed injection. No special venting beyond standard parting line clearance.

- Condition B (Enhanced Venting): Single-stage high-speed injection, but with an additional dedicated vent channel (cross-sectional area ~20 mm²) installed at the final fill location.

- Condition C (Profiled Injection): Two-stage injection profile: a slow fill phase until approximately 60% of the cavity volume was filled, followed by a rapid switch to high-speed fill for the remaining 40%.

- Condition D (Combined Strategy): Application of both the profiled injection (Condition C) and the enhanced venting (Condition B).

Post-casting evaluation involved measuring the density (specific gravity) of sectioned samples from different locations using the Archimedes principle. The density drop from the theoretical maximum is a direct indicator of volumetric porosity in casting. Furthermore, to assess the susceptibility of the castings to blistering or inflation, samples were subjected to a solution heat treatment at 500°C for 1 hour. The post-treatment density drop and visual inspection of blistered surfaces provided a severity index for subsurface porosity in casting.

Results and Analysis: Unveiling the Pressure-Velocity-Defect Nexus

The data collected paints a clear and compelling picture of the mechanisms driving porosity in casting formation.

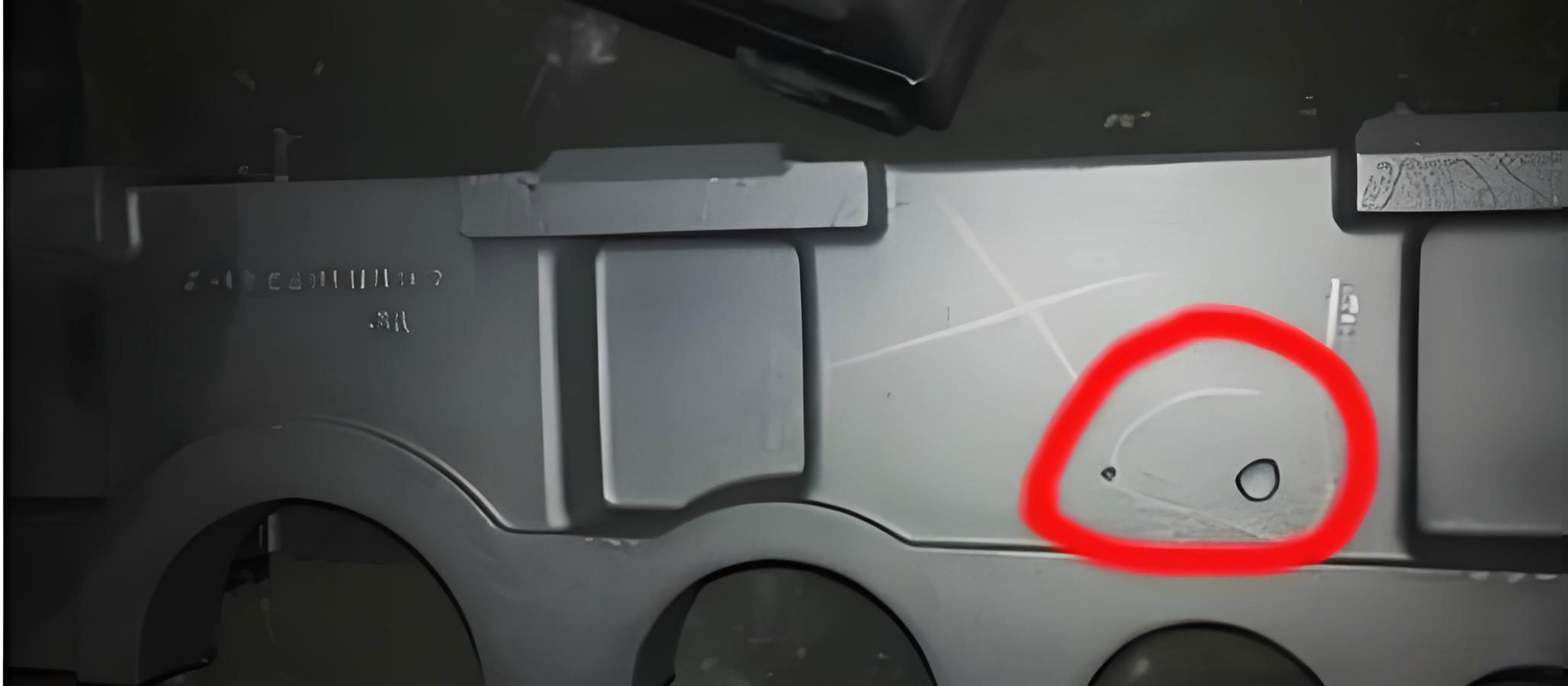

Condition A: Baseline High-Speed Fill

Under the conventional single-stage high-speed fill, the results confirmed the suspected adverse dynamics. The gas pressure $P_{gas}$ started near atmospheric levels (~100 kPa absolute) at the gate but rose precipitously along the flow path due to rapid compression and turbulent entrapment. At the final fill point near the overflow, $P_{gas}$ peaked at approximately 400 kPa—a fourfold increase. Concurrently, the metal fill velocity $v$ exhibited a dramatic decay. Starting at around 45 m/s near the gate, it plummeted to below 10 m/s in the final regions. The local specific gravity (SG) of the casting mirrored this velocity drop, falling from near-theoretical values (>2.60) to below 2.55 in low-velocity zones.

The correlation is summarized in the following relationship derived from the data set:

$$ v(x) \approx v_0 \cdot e^{-k \cdot P_{gas}(x)} $$

$$ \text{SG}(x) \approx \text{SG}_{max} – \alpha \cdot (v_0 – v(x)) $$

where $v_0$ is the gate velocity, $k$ is a damping constant related to flow resistance, and $\alpha$ is a material/process constant. Locations with SG < 2.57 consistently revealed macro-porosity upon sectioning. This established the critical benchmark: high end-of-fill gas pressure leads to low fill velocity, which directly causes severe porosity in casting.

| Location (Distance from Gate) | Gas Pressure, $P_{gas}$ (kPa) | Fill Velocity, $v$ (m/s) | Specific Gravity (SG) | Qualitative Porosity |

|---|---|---|---|---|

| Near Gate (0 mm) | 105 ± 5 | 45 ± 2 | 2.68 | None |

| Mid-Cavity (100 mm) | 220 ± 15 | 18 ± 3 | 2.63 | Minor |

| End-of-Fill (200 mm) | 395 ± 20 | 8 ± 2 | 2.52 | Severe |

Condition B: Effect of Strategic Venting

Introducing a dedicated vent at the end-of-fill location produced a transformative effect. While the gate pressure and initial fill velocity remained similar to Condition A, the story at the final location changed drastically. The peak $P_{gas}$ was capped at approximately 180 kPa—less than half the baseline value. This pressure relief had an immediate effect on the metal dynamics: the fill velocity $v$ at the same end point increased to about 25 m/s, a more than threefold improvement. The specific gravity in this region rose accordingly to 2.65, indicating a near-sound casting. The density drop after heat treatment was minimal, and blister count reduced from dozens to just a few. This single modification demonstrated that targeted reduction of $P_{gas}$ is a potent method for mitigating porosity in casting.

Condition C: Effect of Profiled Slow-Fast Injection

Altering the injection profile itself, without extra vents, also proved highly effective. By using a slow shot to fill the first 60% of the cavity, the air is displaced more gently, allowing it more time to escape through standard vents. When the switch to high speed occurs, the volume of remaining air to be compressed is significantly smaller. The data showed that the peak $P_{gas}$ under this regime was reduced to about 250 kPa. More importantly, the metal velocity in the final stage remained high, measured at ~30 m/s, because it was not fighting against an already-high pressure built up from the start. The resultant SG was high and uniform (>2.66) across the casting. This confirms that managing the gas compression history is key to controlling the final porosity in casting.

Condition D: The Synergistic Optimal Solution

The most impressive results were achieved by combining both strategies: profiled injection and enhanced end-of-fill venting. This approach minimized the initial gas volume (via slow fill) and provided an optimal escape path for the remaining compressed gas (via dedicated vent). The recorded peak $P_{gas}$ was the lowest of all conditions, at approximately 150 kPa. Consequently, the end-of-fill velocity soared to over 35 m/s. The castings produced were exceptionally sound, with specific gravity measurements consistently at the theoretical maximum across all sections. Even after the aggressive 500°C heat treatment, no blisters or measurable density drop occurred, indicating the virtual elimination of subsurface porosity in casting. This condition represents the process optimum derived from this study.

| Process Condition | Peak Gas Pressure, $P_{gas, max}$ (kPa) | Local Fill Velocity, $v$ (m/s) | As-Cast Specific Gravity | Post-HT Blister Severity | Overall Porosity Rating |

|---|---|---|---|---|---|

| A: Baseline High-Speed | 395 | 8 | 2.52 | Very High | Severe |

| B: High-Speed + Vent | 180 | 25 | 2.65 | Low | Minor |

| C: Profiled Injection | 250 | 30 | 2.66 | Moderate | Very Low |

| D: Profiled + Vent | 150 | 35 | 2.68 | None | Negligible |

The integrated analysis leads to a definitive empirical model. The final quality metric $Q$ (where higher $Q$ indicates less porosity in casting) can be expressed as a function of the key controllable variables:

$$ Q \propto \frac{v_{end}}{P_{gas, end}} \approx \beta \cdot \frac{1}{V_{gas, initial}} \cdot A_{vent} \cdot f(t_{slow}) $$

Here, $v_{end}$ and $P_{gas, end}$ are the velocity and pressure at the end-of-fill, $\beta$ is a machine/die constant, $V_{gas, initial}$ is the volume of air to be compressed, $A_{vent}$ is the effective venting area, and $f(t_{slow})$ is a function describing the efficacy of the slow-shot phase in reducing $V_{gas, initial}$. Maximizing $Q$ requires minimizing $P_{gas, end}$ and maximizing $v_{end}$, which is precisely what Conditions B, C, and D achieved through different means.

Discussion and Implementation Strategy

The implications of this research are profound for practical die-casting operations focused on reducing porosity in casting. The study moves defect control from a trial-and-error approach to a principle-based strategy centered on in-cavity gas dynamics.

1. Diagnostics First: The experimental methodology itself can be adapted for production troubleshooting. Identifying locations of low fill velocity (through short-shot studies or simulation) directly points to potential zones of high gas pressure and hence porosity in casting.

2. Venting as a Precision Tool: Vents should not be an afterthought. Their size, location, and timing (via valving systems) must be engineered based on the filling pattern. The goal is to provide a low-resistance escape path for air from the last areas to fill, keeping $P_{gas}$ below a critical threshold—empirically found to be around 200 kPa for the tested geometry to avoid severe porosity in casting.

3. Injection Profiling is Non-Negotiable: A single-stage high-speed shot, while seemingly efficient, is fundamentally flawed for complex cavities. A properly tuned slow-fast profile is essential to stage the gas displacement. The optimal switchover point from slow to fast shot must be determined for each die, often between 50-70% cavity fill volume.

4. The Synergy Principle: For critical components, especially those requiring subsequent heat treatment or holding pressure, the combined use of profiled injection and optimized venting (Condition D) offers the highest guarantee against porosity in casting. This approach addresses both sides of the equation: reducing the source of pressure (trapped air volume) and providing a relief valve for the remainder.

5. Quantifiable Process Windows: The research establishes quantifiable targets:

- Target End-of-Fill Gas Pressure: $P_{gas, end} < 200$ kPa.

- Target End-of-Fill Metal Velocity: $v_{end} > 20$ m/s (geometry dependent).

- Target As-Cast Specific Gravity: $SG > 2.65$ for A360-type alloy.

Monitoring these parameters, possibly via advanced process control sensors, can provide real-time quality assurance.

Conclusion

This investigation systematically decouples the factors leading to porosity in casting in aluminum die casting, shifting the spotlight onto the previously underrated variable of in-cavity gas pressure. The evidence conclusively demonstrates that the decay in metal fill velocity along the flow path is not an inevitable characteristic but a direct consequence of increasing gas counter-pressure. Therefore, the strategic mitigation of porosity in casting is fundamentally a gas pressure management problem.

The key findings are:

- A strong inverse correlation exists between the local gas pressure and the local metal fill velocity. High $P_{gas}$ causes low $v$, which in turn leads to high levels of porosity in casting and low specific gravity.

- Introducing dedicated venting at final fill locations can reduce peak gas pressure by over 50%, correspondingly increasing fill velocity by a factor of three or more, and significantly reducing defect severity.

- Implementing a slow-fast injection profile effectively reduces the initial volume of air to be compressed, lowering peak gas pressure and preserving end-of-fill velocity, thereby yielding castings with minimal porosity in casting.

- The synergistic application of both optimized venting and profiled injection represents the process optimum. This combination reduces end-of-fill gas pressure to its lowest achievable level, maximizes metal velocity, and produces die castings that are essentially free from porosity in casting, even when subjected to demanding post-casting heat treatments.

In essence, controlling the journey and destination of the air inside the die is as critical as controlling the journey of the metal. By adopting the principles outlined here—actively managing gas pressure through intelligent venting and shot profile design—die casters can transform their approach to quality control, moving predictably toward the goal of eliminating porosity in casting and achieving consistently sound, high-integrity aluminum components.